Multistage spiral feeding mechanism for automatic powder filling line

A technology of automatic filling and feeding mechanism, which is applied in the direction of solid materials, packaging, transportation and packaging, etc., to achieve the effect of reasonable structure design and solving the accuracy and stability of feeding control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

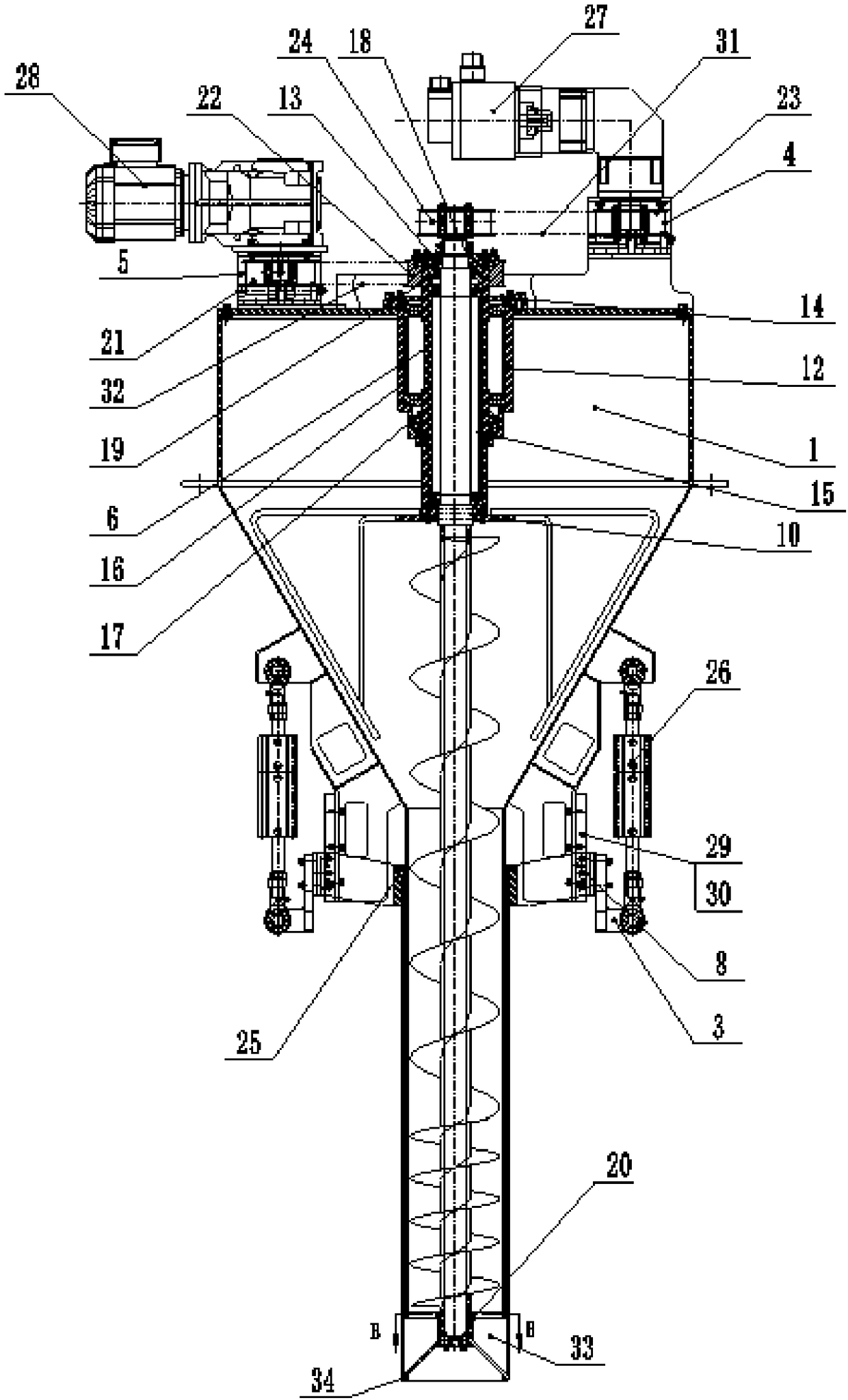

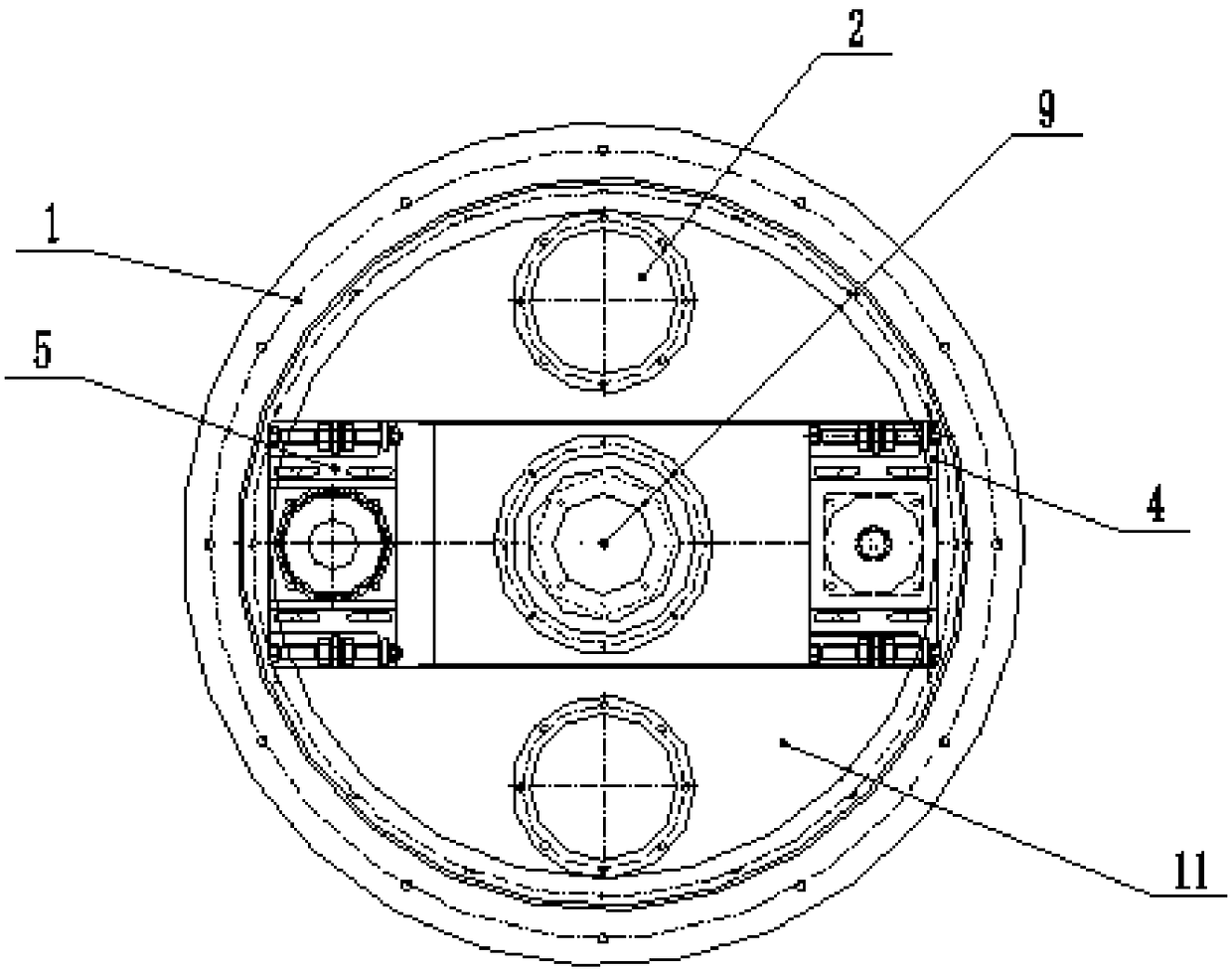

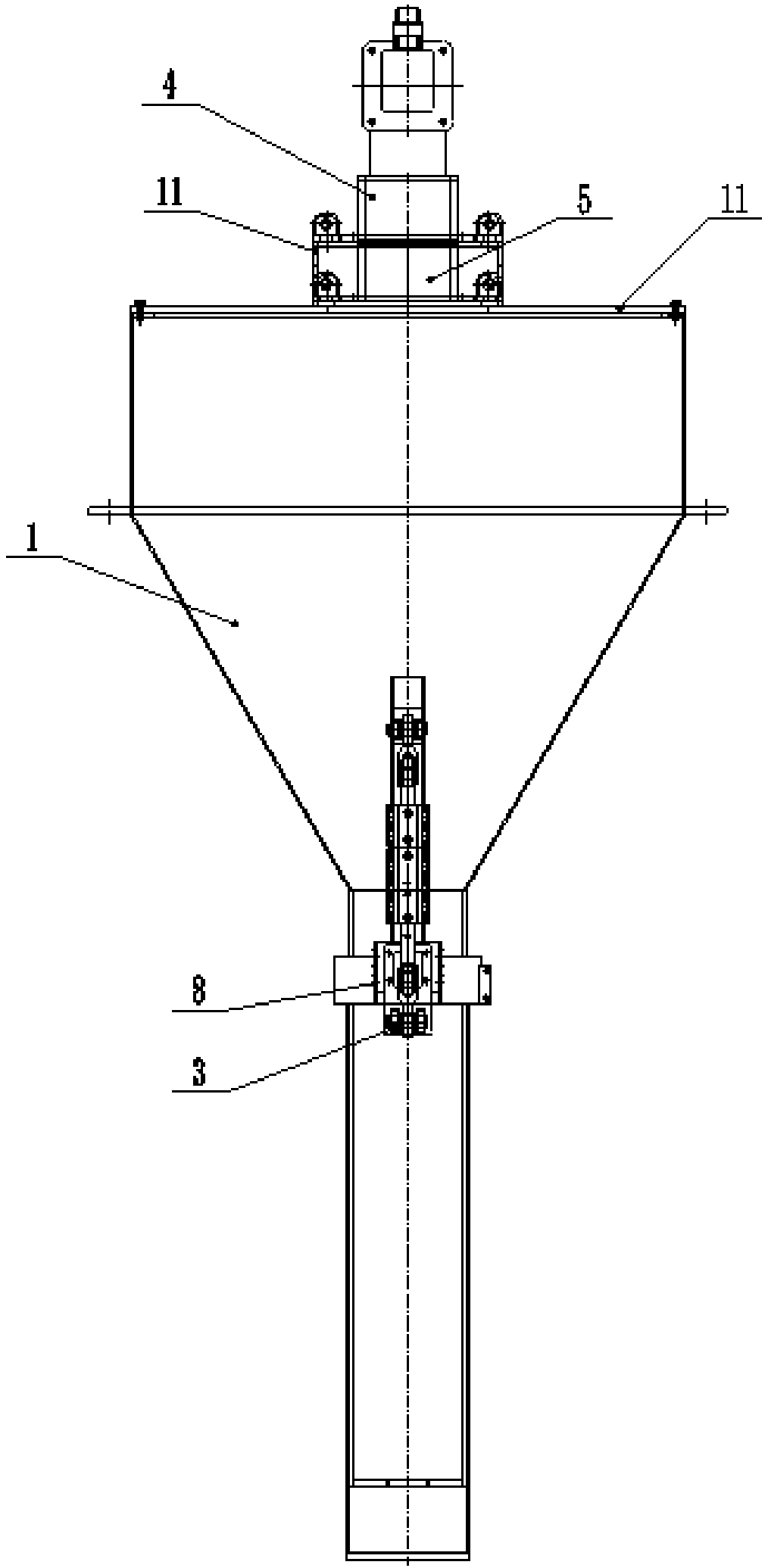

[0018] See attached picture.

[0019] A multi-stage auger feeding mechanism for an automatic powder filling line, including a funnel-type storage tank 1, an end cover 14 is provided on the top of the storage tank 1, and a feed port 2 is provided on the end cover. The bottom of the barrel is connected with a multi-stage feed pipe 7, and the multi-stage feed pipe 7 includes an inner discharge pipe 35, and the inner discharge pipe 35 is covered with an outer discharge pipe 36 that can slide up and down; A longitudinal hollow shaft 6 is installed, and an auger shaft 9 is installed in the rotation of the hollow shaft 6. The top of the auger shaft 9 extends outside the hollow shaft 6. The feed pipe protrudes from the inner discharge pipe, the protruding end of the auger bottom is fixed with a closed cone 34, and an adjustable annular discharge opening is formed between the outer discharge pipe 36 and the closed cone 34; A material leveling motor 28 is installed, and the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com