Automobile part assembling auxiliary device

A technology of auto parts and auxiliary equipment, which is applied in the field of auto parts assembly auxiliary equipment, which can solve the problems of assembly errors, cumbersome and complicated, poor clamping force, etc., and achieve the effect of precise positioning and installation, flexible use angle, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

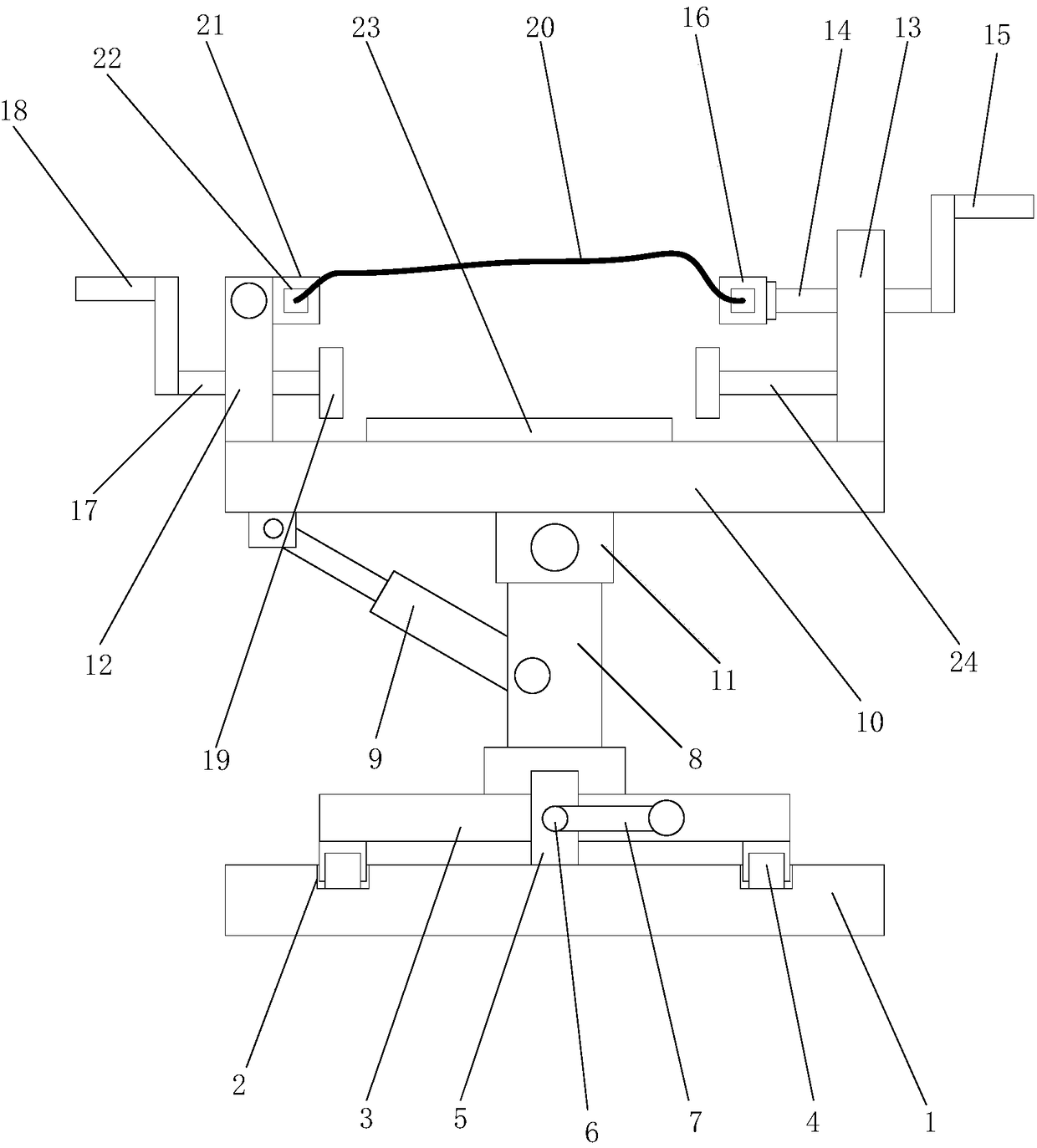

[0010] Such as figure 1 As shown, the automobile parts assembly auxiliary equipment disclosed by the present invention includes: a base 1, a support plate 3, a support column 8, a load plate 10 and an electric telescopic rod 9; two track grooves 2 are arranged in parallel above the bottom plate 1; Four track wheels 4 are installed on the lower side of the plate 3; the track wheels 4 are embedded in the track groove 2, so that the support plate 3 slides in parallel with the bottom plate 1; a front side plate 5 is vertically arranged on the front side of the base 1; On the front side plate 5, a horizontal drive screw rod 6 is rotatably installed; on the front side of the support plate 3, a drive screw hole is provided; The other end is screwed on the driving threaded hole, and the axial direction of the horizontal driving screw 6 is parallel to the slotting direction of the track groove 2; On the center of the lower side of the bearing plate 10; the lower end of the electric te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com