New energy battery cap full inspection machine

A battery cover and new energy technology, applied in the field of new energy battery cap detection equipment, can solve problems such as affecting the test results, damage to the new energy battery cap, and inability to ensure the accuracy of the test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

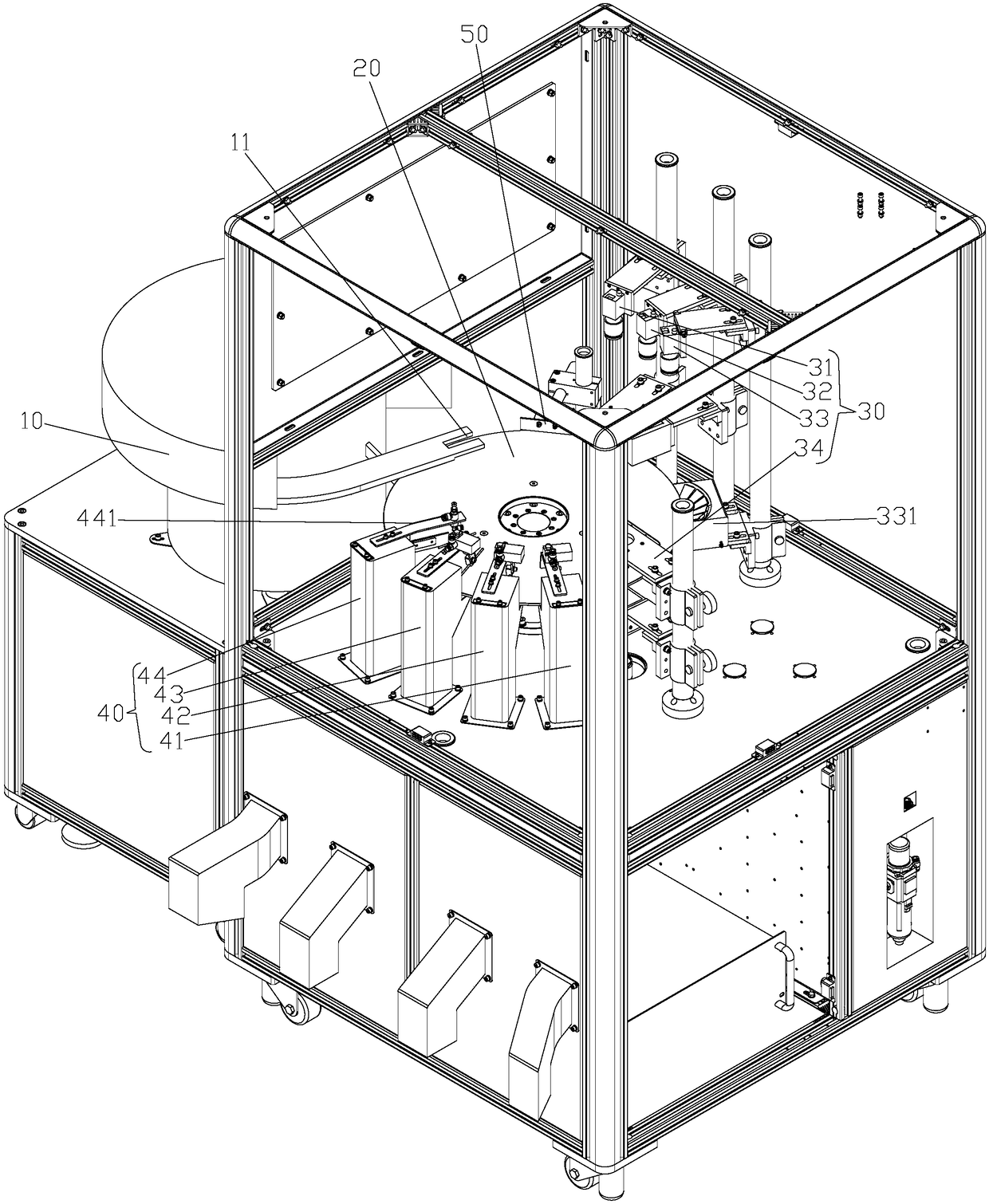

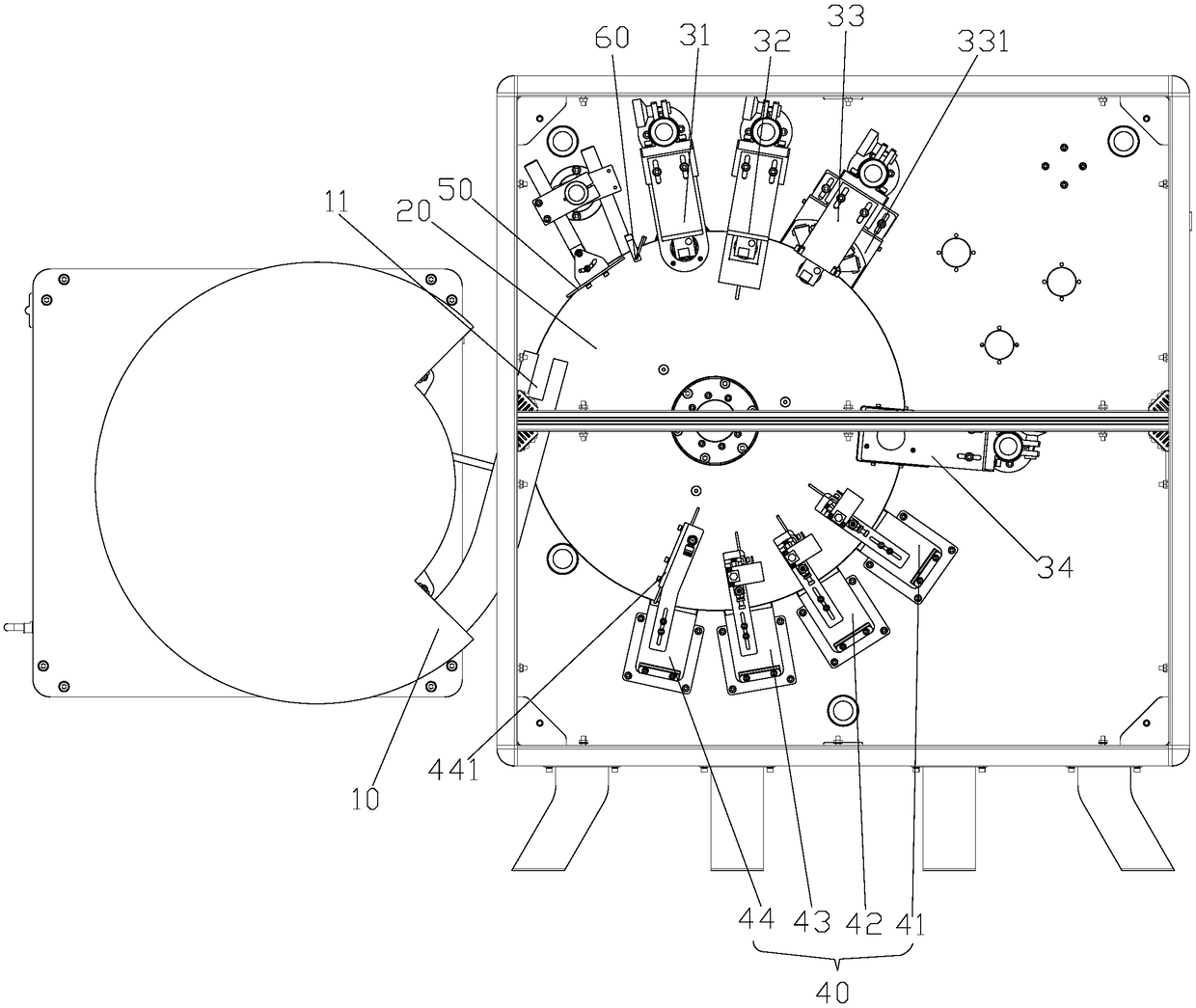

[0020] Referring to the accompanying drawings, a new energy battery cap full inspection machine includes a vibrating feeder 10 arranged in sequence, a glass disc 20, a full inspection mechanism 30 and a screening and rejecting mechanism 40, and the glass disc 20 is located on the vibrating feeder 10. The lower position of the discharge end is provided with a limit stopper 50, and the lower position of the limit stopper 50 is provided with a photoelectric detection switch 60;

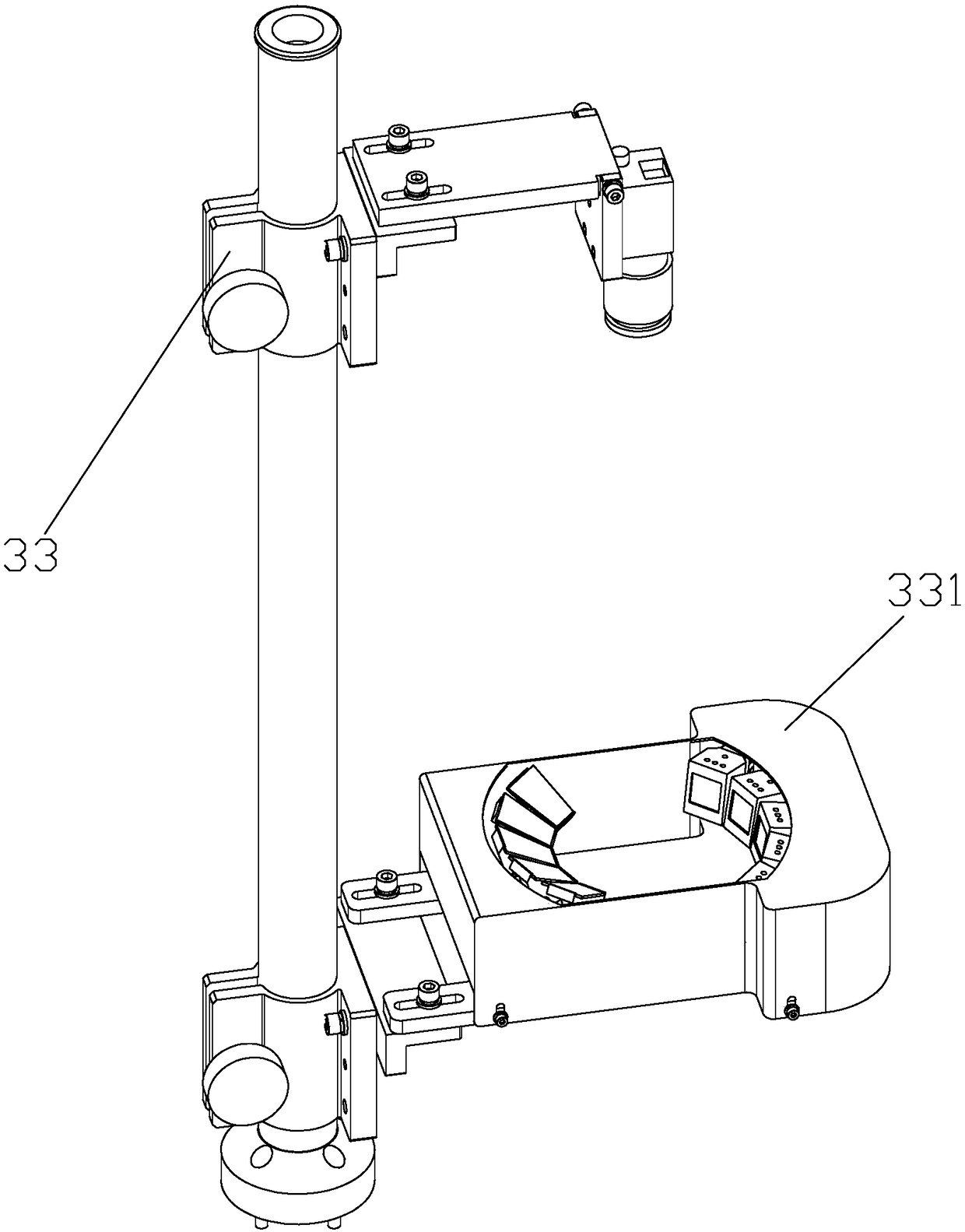

[0021] The full inspection mechanism 30 is arranged at the lower position of the photoelectric detection switch 60, and the full inspection mechanism 30 includes a cap upper surface detection mechanism 31, a cap size detection mechanism 32, a cap inner hole detection mechanism 33, and a cap lower surface arranged in sequence. The detection mechanism 34, the cap inner hole detection mechanism 33 includes a third adjustment pole, a camera assembly is arranged on the third adjustment pole above the glass dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com