Electronic cigarette with MEMS micropump

An electronic cigarette and micro-pump technology, applied in the field of electronic cigarettes, can solve the problems of uncontrollable oil conduction rate, uncertain inhalation safety of discharges, oil frying, etc., to avoid smoking odor and release toxic and harmful substances, consumption Experience convenient and humanized better effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

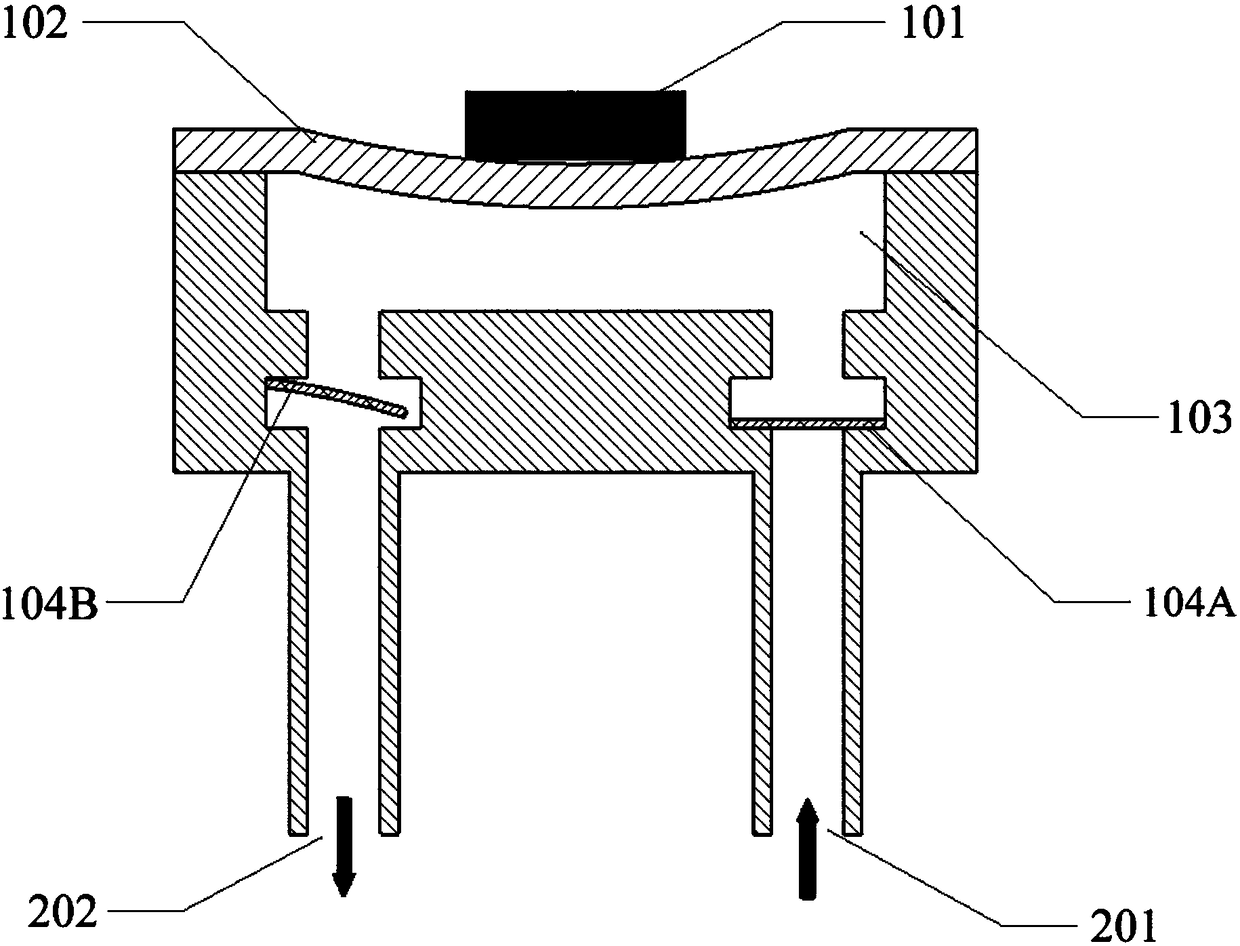

[0029] When smoking the electronic cigarette with the MEMS micropump of the present invention, first inject the smoke oil into the oil storage bin 304 from the smoke oil injection port 303, press the power switch 311 provided on the electronic cigarette housing, and the The battery 307 is electrically connected to the micropump 305 and the heater 309, and the heater 309 is in a preheating state. Under the action of the microcomputer control system 306, the driver 101 drives the elastic pump membrane 302 to generate Vibrate up and down, when the pump membrane 102 protrudes upwards, the volume of the pump chamber 103 increases, at this time the pressure in the pump chamber 103 decreases, and the inlet pump valve 104A at the inlet 201 of the micropump is opened , the outlet pump valve 104B at the micropump outlet 202 is closed, the e-liquid in the oil storage chamber 304 is sucked into the pump cavity 103, when the driver 101 makes the pump membrane 102 sink downward , the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com