Potato planter

A planter and potato technology, applied in potato planters, planting methods, plant protection, etc., can solve problems such as low degree of automation and limited sowing ridge spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

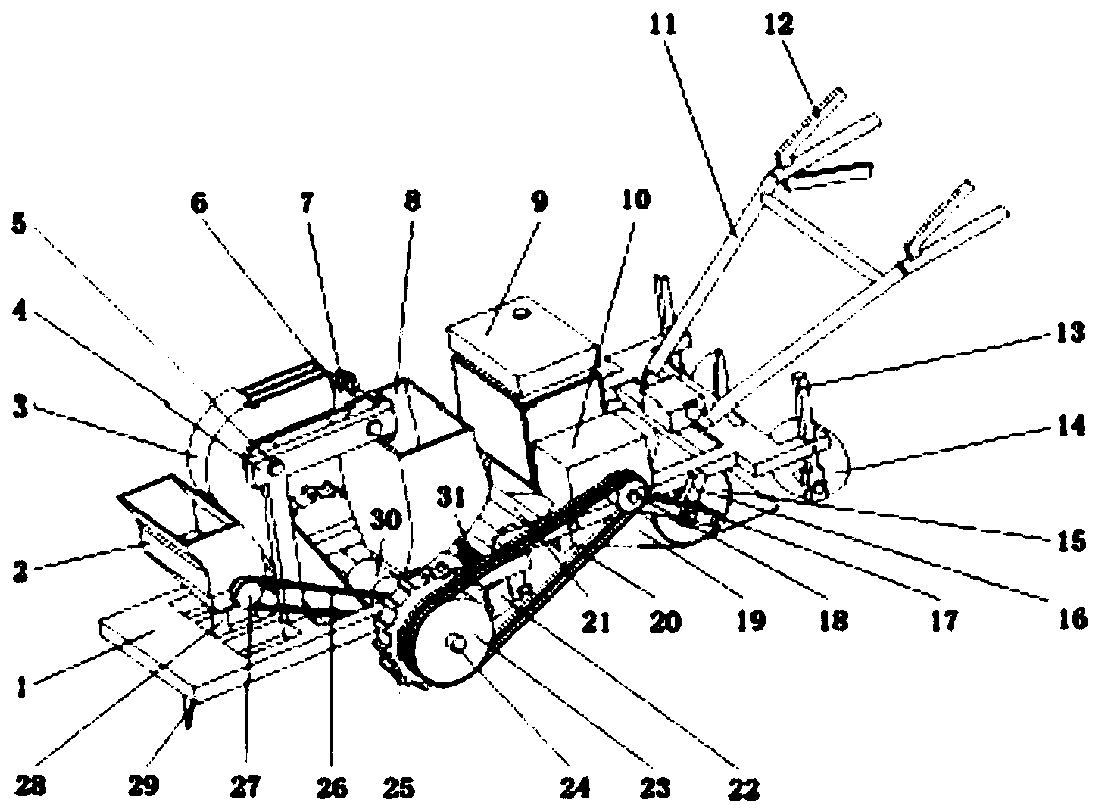

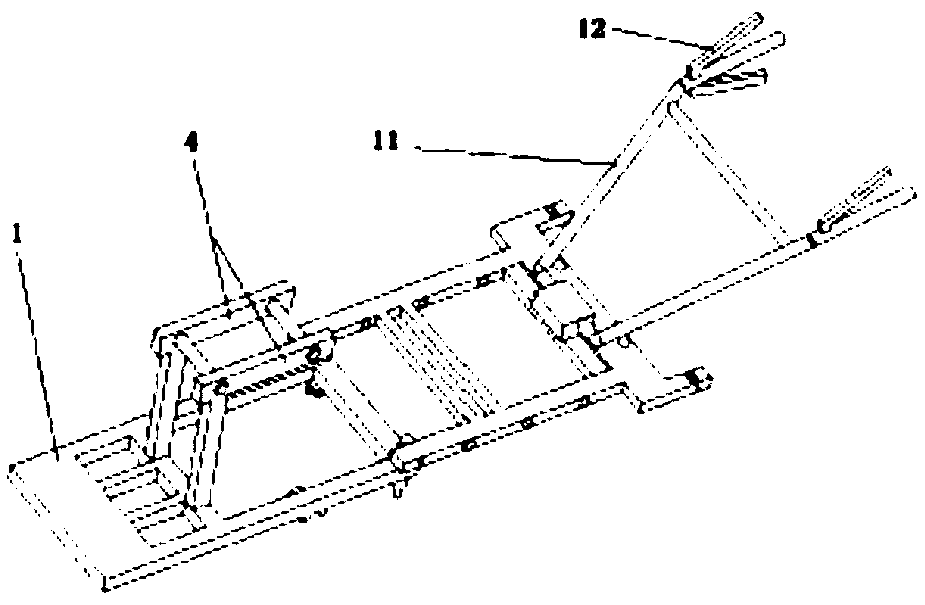

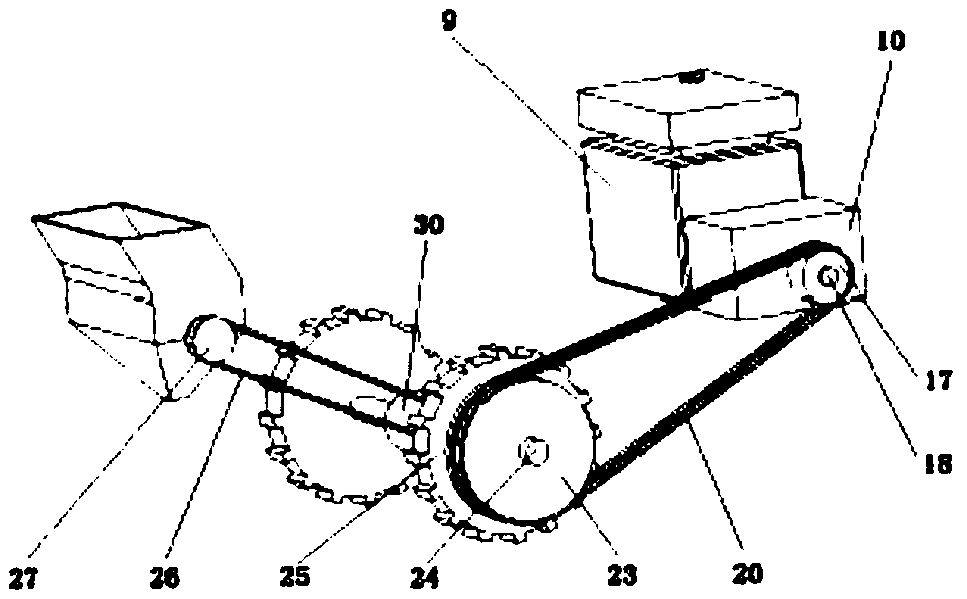

[0021] The present embodiment is a potato planter.

[0022] refer to Figure 1-Figure 7 , the present embodiment potato planter is made up of chassis, seeding mechanism, power transmission mechanism, fertilization mechanism, laminating mechanism, chassis 1 provides support for other parts, and power transmission mechanism is fixed on chassis 1, is installed in the rear portion of sowing mechanism; The fertilization mechanism is installed at the front of the seeding mechanism, and the film covering mechanism is fixed at the lower rear of the chassis 1, which is used for mulching after sowing; a main shaft 24 is installed in the middle of the chassis 1, and the two ends of the main shaft 24 are fixedly connected to the walking wheels 25 and adopt shaft shoulders and openings pin positioning. The planter handle 11 is fixed on the rear end of the chassis 1, and the clutch 12 and the throttle switch on the planter handle 11 control the planter's start, stop and sowing speed. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com