18-phase wind generator direct current grid-connected structure and control method thereof

The technology of a wind turbine and a control method is applied to the DC grid-connected structure of an 18-phase wind turbine and its control field, and can solve the problems of low speed of high-power direct-drive permanent magnet wind turbine, difficult to increase terminal voltage, and different output voltages, etc. , to achieve the effect of reducing wire diameter, reducing insulation level and voltage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

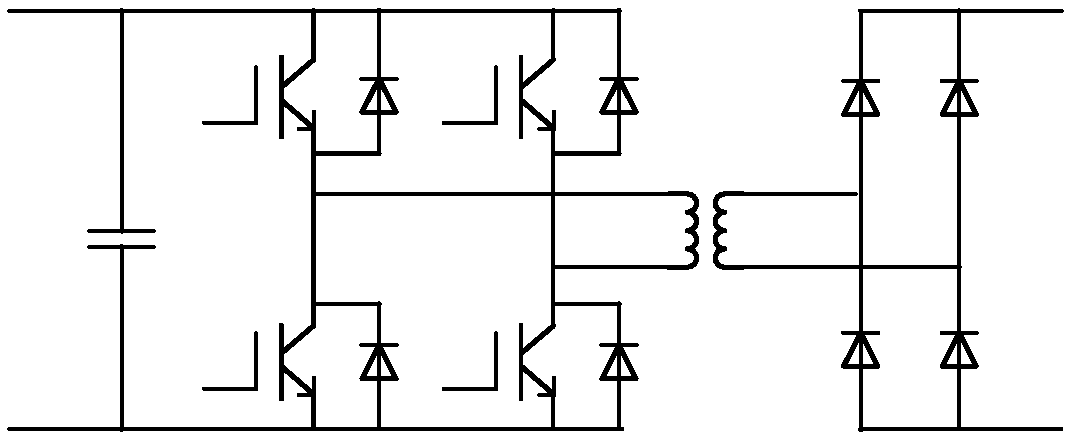

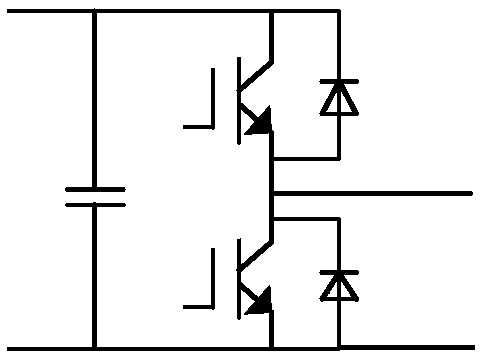

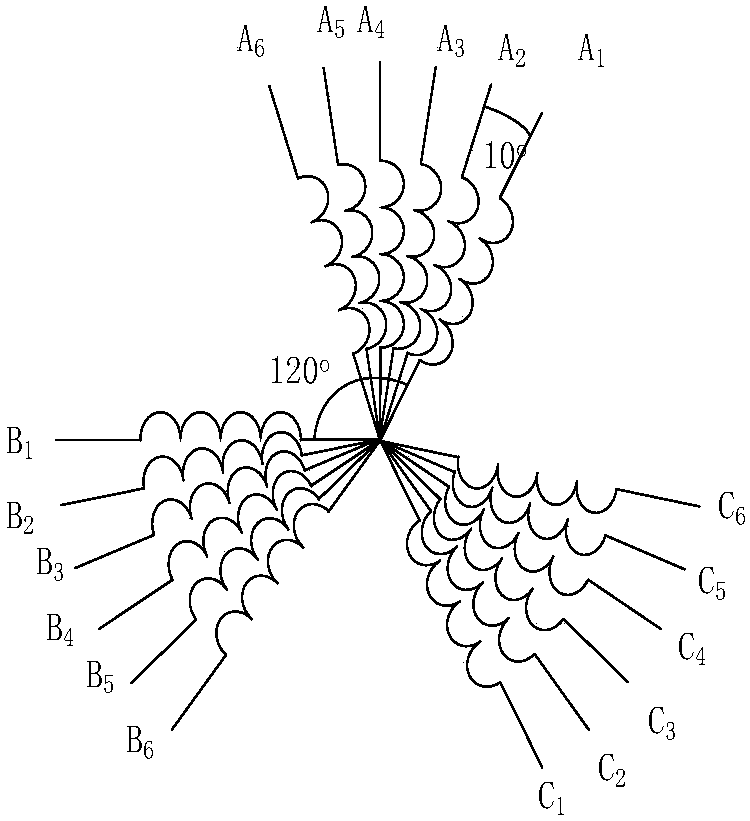

[0054] Figure 4 It is a DC grid-connected structure diagram of 18-phase wind turbines, which includes 18-phase direct-drive permanent magnet wind turbines, 6 three-phase uncontrolled rectifier bridges, 6m parallel isolated full-bridge DC-DC converters and 6m half-bridges submodule. The rotor of the 18-phase generator is coaxially connected with the wind turbine installed in the wind farm. The stator of the 18-phase generator has 18 windings, and every 3 windings form a set of three-phase AC windings, and a total of 6 sets of three-phase AC windings are formed. Each set of windings is commutated by a three-phase uncontrolled rectifier bridge, and then connected to m parallel isolated full-bridge DC-DC converters. Each parallel isolated full-bridge DC-DC converter is connected to a half-bridge sub-module. The positive and negative poles of the output terminals of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com