Button type battery assembly mechanism

A battery assembly and button technology, which is applied in the field of button battery assembly mechanism, can solve the problems of high-speed production and low efficiency, and achieve the effects of simple structure, accurate assembly efficiency and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

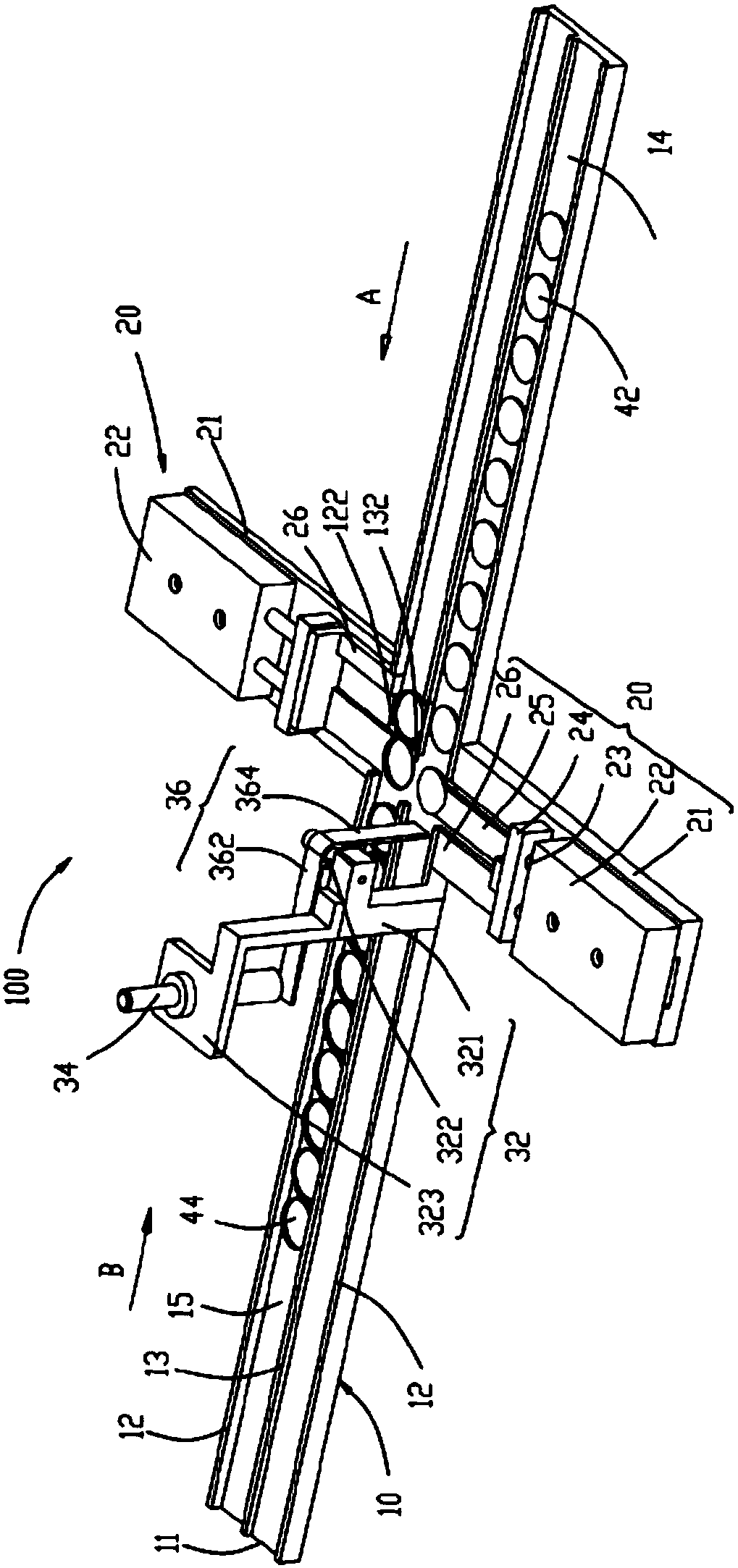

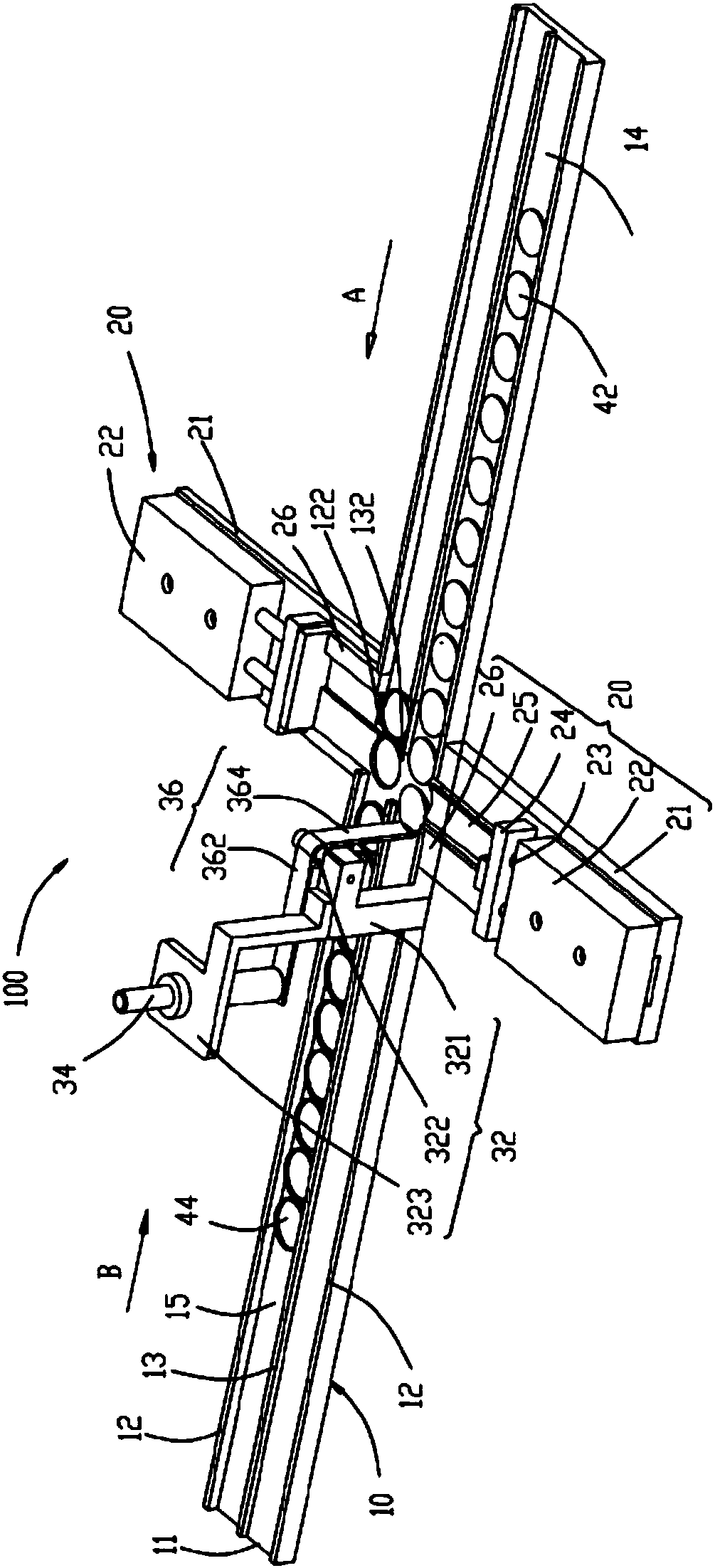

[0019] see figure 1 A preferred embodiment of the present invention discloses a button-type battery assembly mechanism 100, including a guide rail 10, two driving mechanisms 20 oppositely arranged on two sides of the guide rail 10, and an alarm mechanism 30 arranged on one side of one of the driving mechanisms 20. The guide rail 10 includes a base plate 11, side walls 12 formed on both sides of the base plate 11, and a partition wall 13 formed in the middle of the base plate 11 parallel to the side walls 12, thereby dividing the guide rail 10 into parallel first flow passages 14 and second flow passages. Runner 15. A notch 122 is defined on each side wall 12 , and the notch 122 is roughly located at the middle section of the side wall 12 for matching the driving mechanism 20 . A communication port 132 is defined on the partition wall 13 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com