Cylindrical battery cap

A battery and cylindrical technology, applied in the field of cylindrical battery cap structure, can solve the problems of battery leakage and explosion-proof pressure failing to meet battery requirements, poor control of internal air pressure, damage to explosion-proof wire structure, etc., so as to achieve a firm and reliable surrounding connection , Easy to assemble, good explosion-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

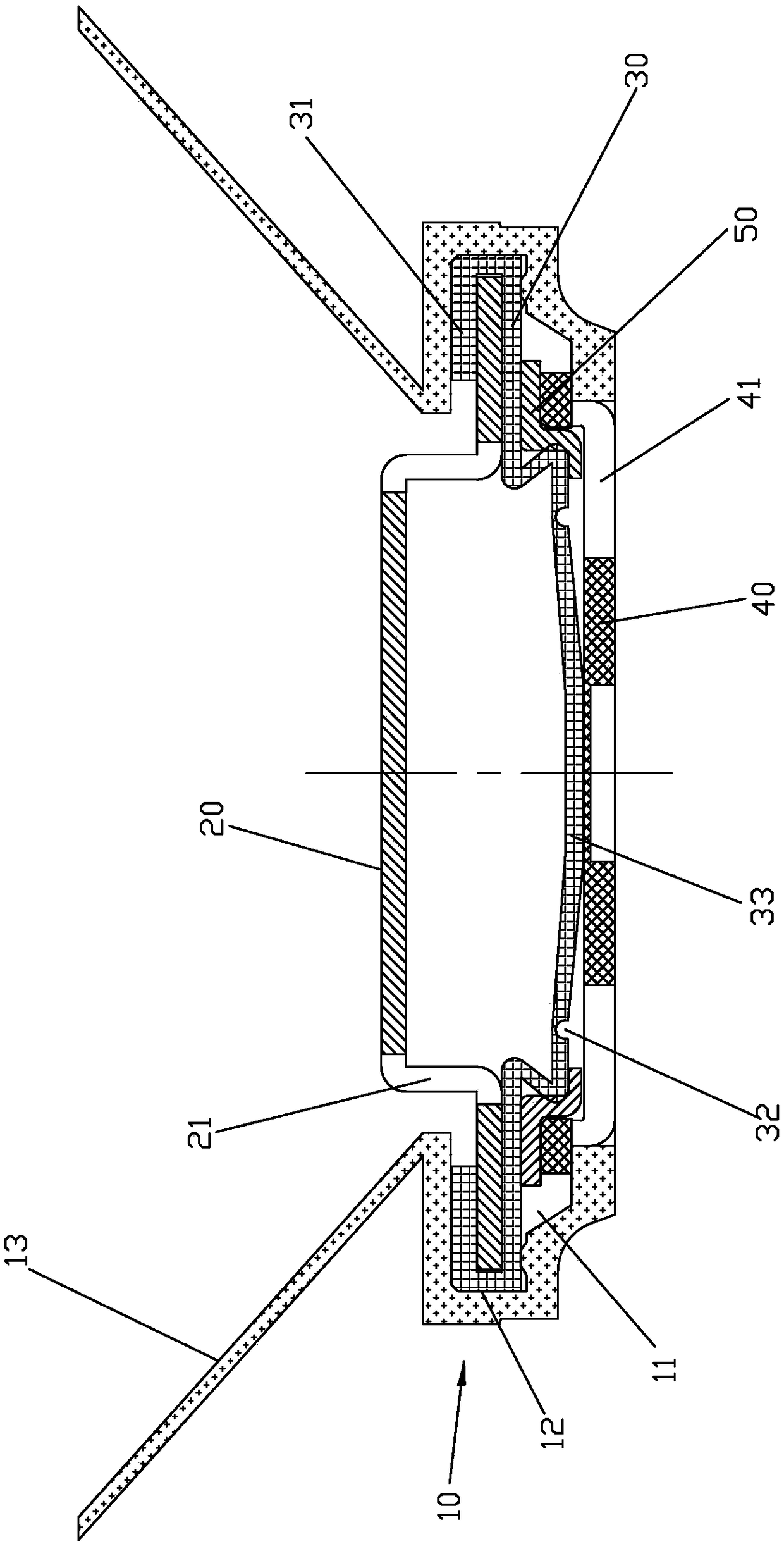

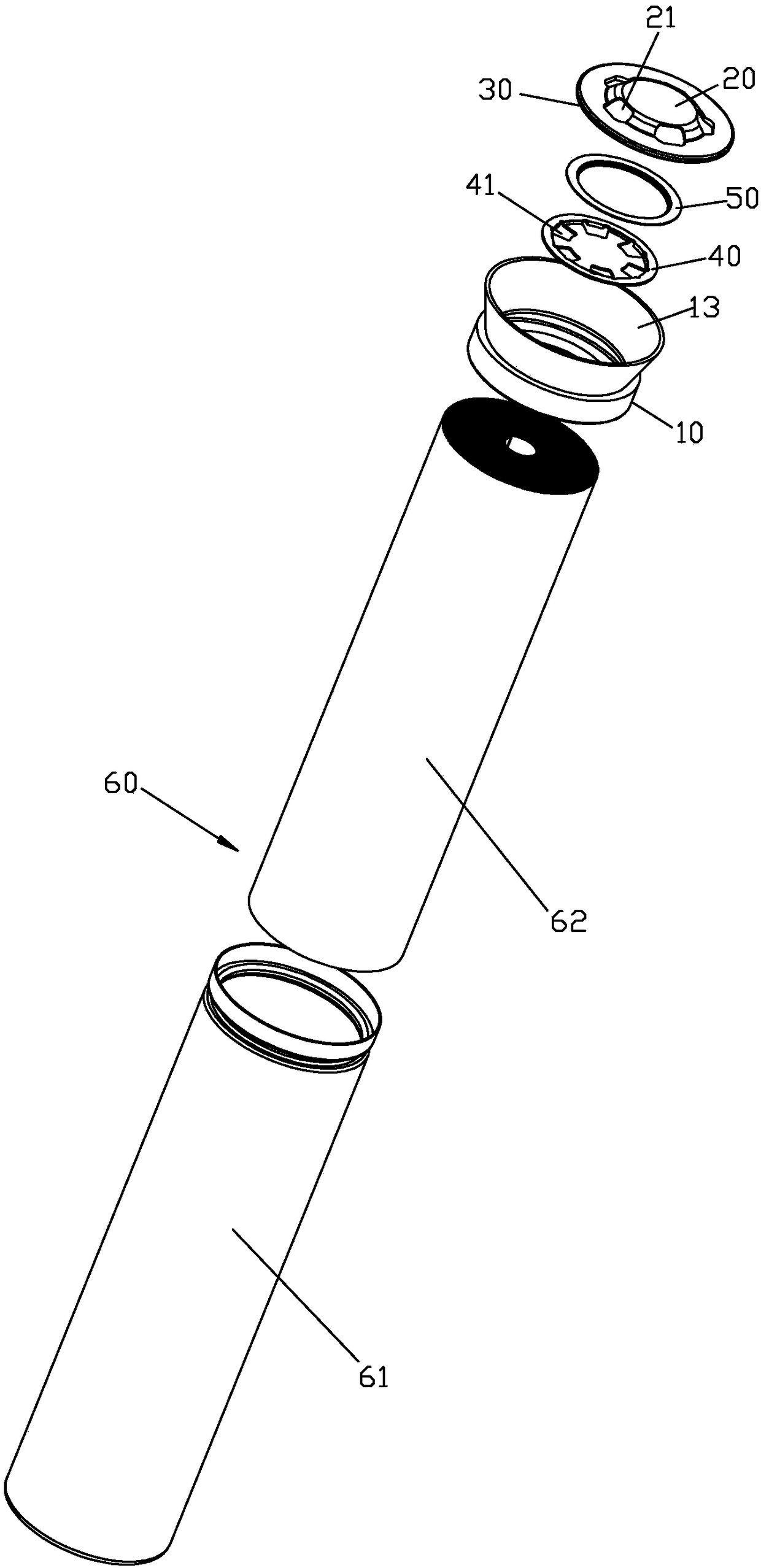

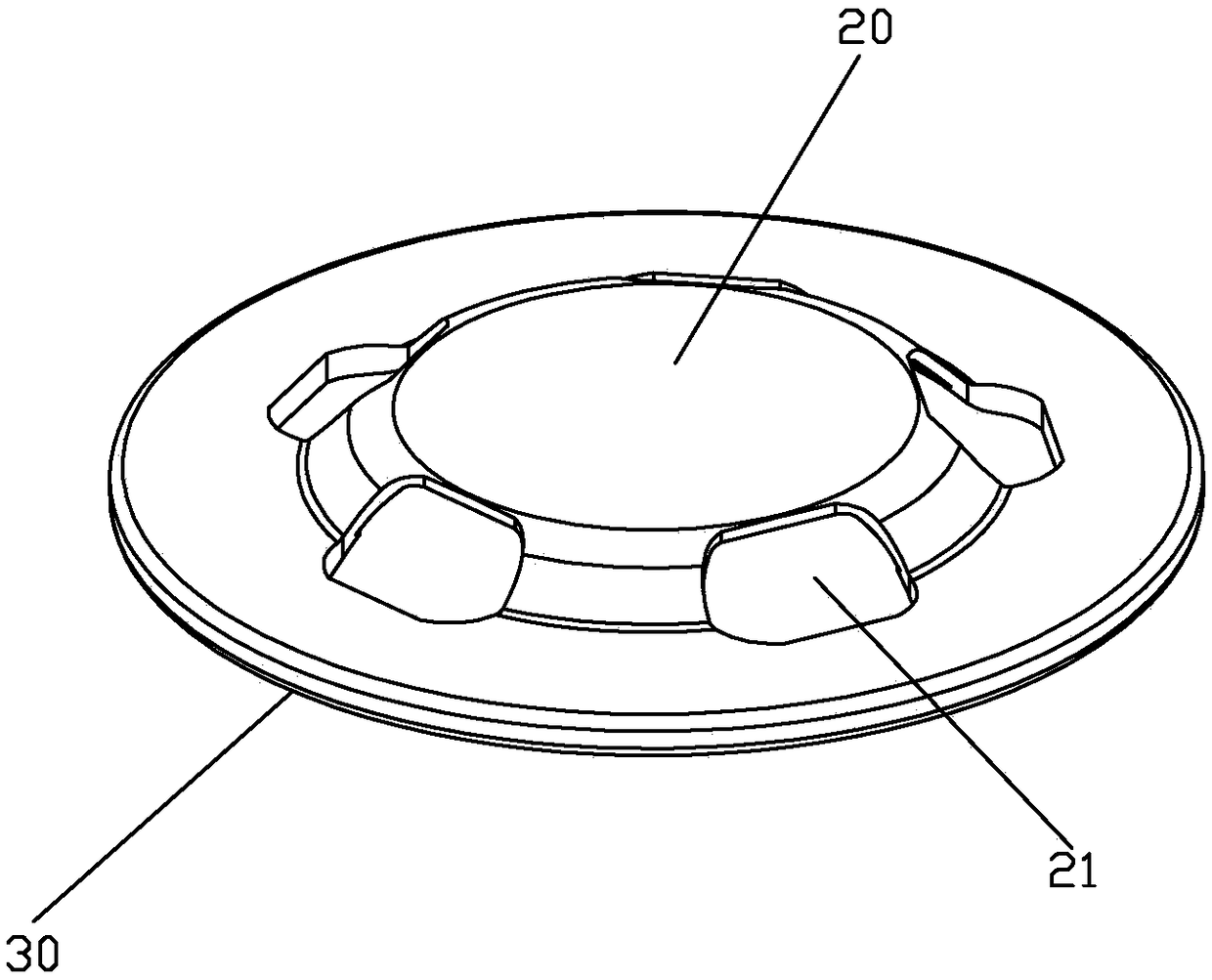

[0032] Cylindrical battery cap, see Figure 1 to Figure 5 , including the mounting seat 10 attached to the cylindrical battery 60 and the cap part installed in the mounting seat 10; the cap part includes a top cover 20, a conductive explosion-proof diaphragm 30, a conductive sheet 40 and an insulating ring 50. This specific Among the embodiments, the conductive explosion-proof diaphragm 30 adopts an aluminum sheet, and the conductive sheet 40 also adopts an aluminum sheet; the top cover 20 is arranged on the conductive explosion-proof diaphragm 30 and the conductive explosion-proof diaphragm 30 circles partially contact and surround the top cover 20 circle parts; the top cover 20 is provided with a first air hole 21 that penetrates up and down, and the conductive explosion-proof diaphragm 30 is provided with an explosion-proof line 31 that can rupture when the internal pressure of the cylindrical battery increases. The explosion-proof line 31 is as The ring-shaped structure, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com