Condensation water recycling heat-supply system based on water-water ejector

A water-water ejector and heating system technology, which is applied in the heating system, hot water central heating system, household heating and other directions, can solve problems such as the drop of condensate water, increase the return water temperature, reduce the deaerator and High steam extraction, flexible peak shaving and thermo-decoupling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

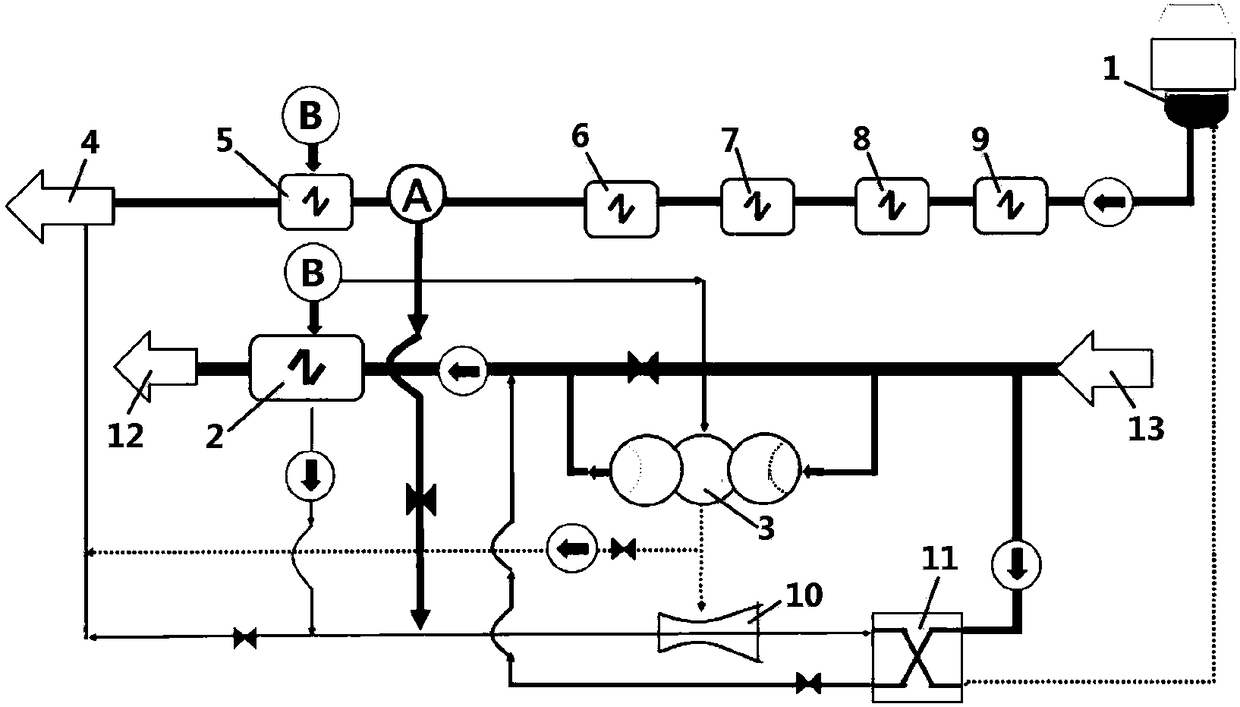

[0016] Example 1: A power plant has installed two 1000MW direct air cooling units. A single steam turbine provides heat.

[0017] The hot well of the condenser is connected to the heat recovery system. The heat recovery system includes 9# low-pressure heater, 8# low-pressure heater, 7# low-pressure heater, 6# low-pressure heater, 5# low-pressure heater, and deaerator, connected in series Connection, the 9# low-pressure heater is connected to the condenser hot well; the heat network water supply and return system includes an absorption heat pump and a heat network heater. The return water of the heating network is connected to the input of the heating network heater, and the output provides heated water supply for the heating network. The heat absorption end of the absorption heat pump is connected to part of the return water of the heat network as the heat absorption medium. (not shown in the figure) is used as a heat release medium for recovering the waste heat of exhaust s...

Embodiment 2

[0038] Embodiment 2: similar to embodiment 1,

[0039] A power plant installed two 1000MW direct air cooling units. A single steam turbine provides heat.

[0040]The hot well of the condenser is connected to the heat recovery system, and the heat recovery system includes 9# low pressure heater, 8# low pressure heater, 7# low pressure heater, 6# low pressure heater, 5# low pressure heater, deaerator, connected in series Connection, the 9# low-pressure heater is connected to the hot well of the condenser; the heating network supply and return water system includes the heating network heater. The return water of the heating network is connected to the input of the heating network heater, and the output provides heated water supply for the heating network.

[0041] First, high temperature hydrophobic.

[0042] The heating steam of the heat network heater comes from the five-stage extraction steam B or the middle exhaust steam.

[0043] Part of the five-stage extraction steam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com