Tapered-land thrust pad with elastic supporting structures

A technology of elastic support and thrust pad, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of unbalanced load of bearings, reduction of bearing lubrication performance, large thrust bearing pad force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

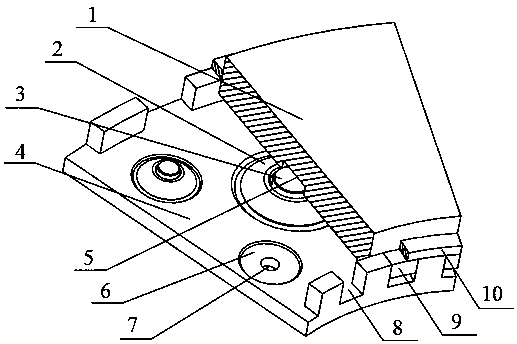

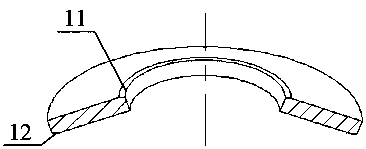

[0012] In combination with the illustrations, an inclined thrust pad with an elastic support structure is composed of an inclined thrust pad 1, a disc spring 2, a positioning column 3 and a cage 4; its characteristic is that the geometric center of the cage 4 and the corners around it are , a total of 5 positioning columns 3 are installed, and a butterfly spring 2 is installed on each positioning column 3; the inclined thrust tile 1 is placed on the cage 4 equipped with positioning columns and butterfly springs, and the upper pressure plate 10 is welded to form A sloped thrust shoe with an elastic support structure is proposed. The inclined-plane thrust pad 1 is a fan-shaped tile, and flanges 9 are processed at the inner and outer circular edges of the fan-shaped tile, and the bottom surface of the fan-shaped tile is at the position where the positioning columns are distributed, and the circles that the positioning columns can enter are respectively processed. Groove 5, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com