Slant supporting member

A component and oblique technology, applied in the field of oblique support components, can solve problems such as damage, loss, deformation of yacht stern plates, etc., and achieve the effect of preventing accidental fall, reasonable structure, and adjustable overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

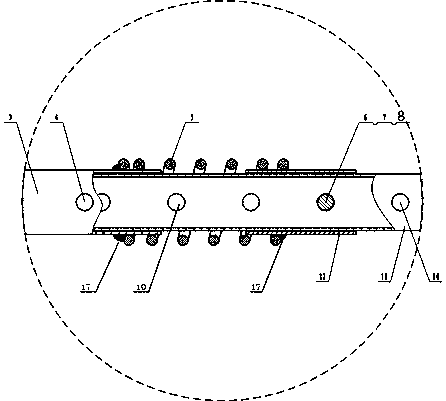

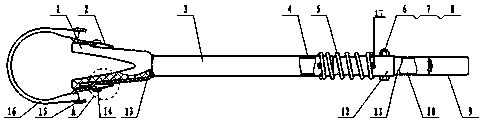

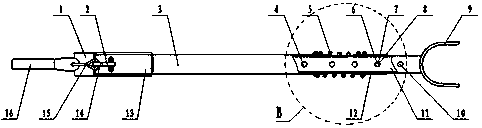

[0015] Embodiment 1, reference Figure 1-4 , an obliquely supported member, including a hollow tubular fixed guide rod 3, a hollow tubular movable guide rod 12 with the same inner diameter as the fixed guide rod 3, shorter in length and arranged in gaps, the fixed guide rod 3 and the movable guide rod The rods 12 are respectively fixed with retaining rings 17, and the fixed guide rod 3 and the movable guide rod 12 between the two retaining rings 17 are provided with damping springs 5. The first fixing hole 6 on the side; the left end of the fixed guide rod 3 is fixed with a V-shaped bracket 13, and the two branches of the V-shaped bracket 13 are respectively punched out to bend out the hanging ears 14, and the elastic locking pieces are fixed respectively. 2. The free end of the elastic locking piece 2 abuts against the inner side of the hanging ear 14, and a V-shaped buffer block 1 is embedded in the two branches of the V-shaped bracket 13, and the V-shaped buffer block 1 can...

Embodiment 2

[0016] Embodiment 2, the other is the same as the embodiment, the difference is that the tube wall of the fixed guide rod 3 on the left side of the retaining ring 17 offers a third fixing hole 4 that runs through both sides of the tube wall, and a bolt can pass through the tube wall. After entering the third fixing hole 4 and one of the second fixing holes 10, screw the self-locking nut to fix the fixed guide rod 3 and the guide post 11 together. In this way, it is converted into a rigid support, because the third fixing holes 4 can be aligned with the remaining second fixing holes 10 respectively, and then pass through them with connecting bolts, and tighten and fix them with self-locking nuts. There are seven combinations of rigid support lengths in total. , so that it matches the distance from the supporting wheel of the trailer to the supported position of the yacht motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com