Fabricated frame-shear structure wall split-level connecting structure and splicing method

A frame-shear structure and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as poor structural integrity, and achieve the effects of enhancing integrity, saving learning costs, and speeding up construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Such as Figure 1-Figure 33 As shown, the assembled frame-shear structure wall split-level connection structure of the present invention mainly includes: prefabricated lower column ( Image 6 ), prefabricated upper columns ( Figure 9 ), prefabricated bottom half-floor / top half-floor walls ( Figure 15 ), prefabricated middle wall ( Figure 18 ), prefabricated roof beams ( Figure 21 ) and foundation beam ( Figure 24 ) and the I-shaped column-wall connection key used for the connection between the above components ( Figure 22 ) and channel beam-wall connection key ( Figure 23 ).

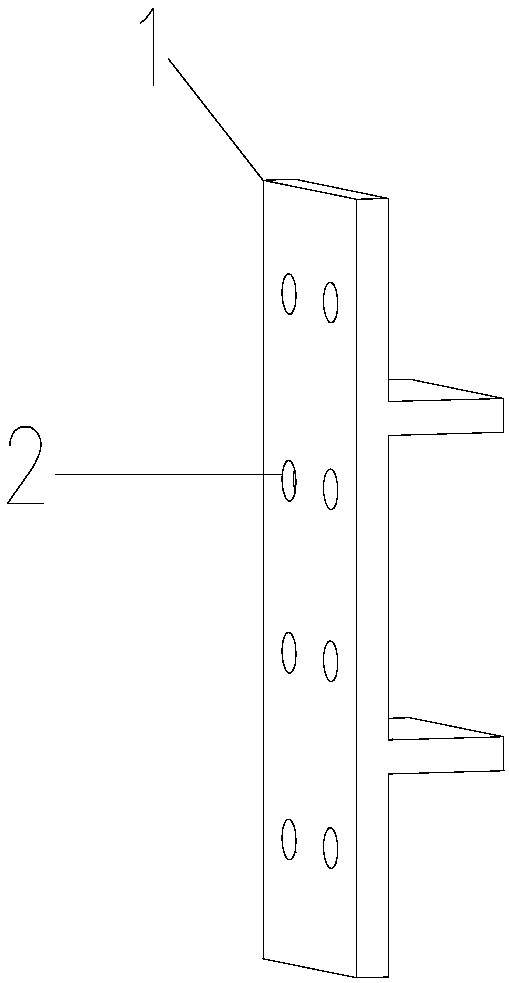

[0070] (1) if figure 1 As shown, the specific structure and production process of the column-wall embedded parts are as follows:

[0071] Column-wall embedded parts ( figure 1 ) consists of a ribbed steel plate I1 and a round hole I2, one side of the ribbed steel plate I1 is provided with ribs in parallel up and down, and the other side of the ribbed steel plate I1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com