Rotating furnace scrap steel feeding hopper

A technology of feeding into the converter, which is applied in the field of feeding hoppers and scrap steel into the hopper, which can solve the problems of accumulation at the furnace mouth and increasing the proportion of scrap steel into the converter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

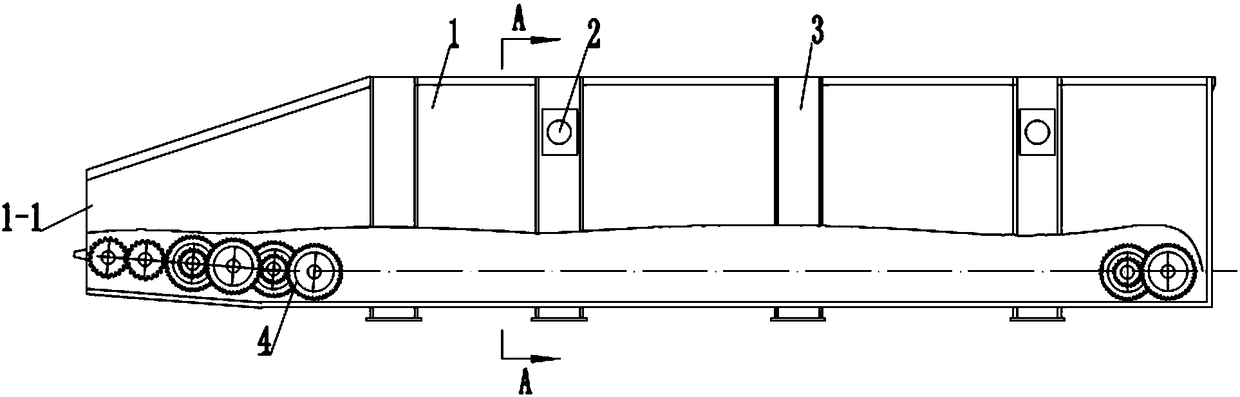

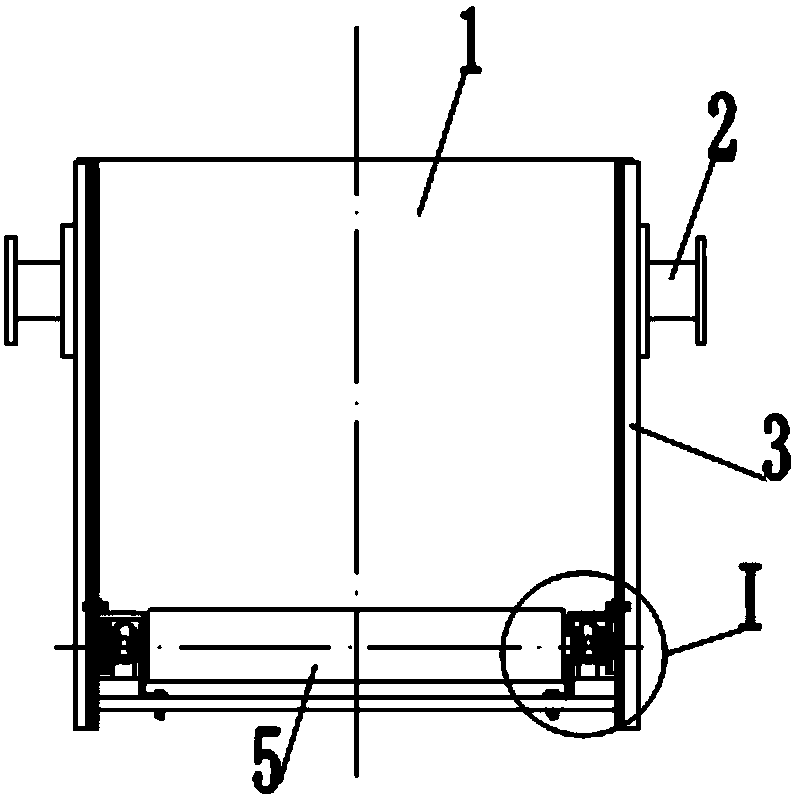

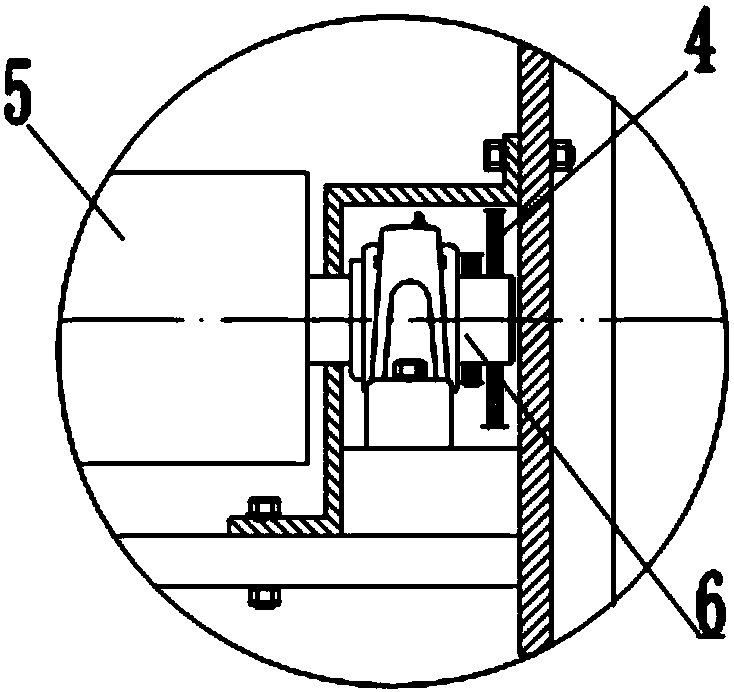

[0023] see figure 1 , figure 2 ,, image 3 , Figure 4 , Figure 6 , the present invention is a hopper for adding scrap steel to a converter, which includes a box body 1, lifting lugs 2 and reinforcing ribs 3; Port 1-1, a group of reinforcing ribs 3 are arranged outside the two side walls of the box body 1; the reinforcing ribs 3 adopt a channel steel structure with a thickness of 10mm, and are fixed on the side walls of the box body 1 by welding; Four sets of ears 2 are symmetrically arranged in front, back, left and right, and are respectively fixedly installed on the reinforcing ribs 3 at the corresponding positions; the special feature is that a row of rollers 5 are arranged on the bottom surface of the box body 1, and the rollers 5 Arranged perpendicular to the central axis in the length direction of the bottom surface of the box bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com