Small-scale micro tillage machine with composite walking wheels

A technology of walking wheels and micro-tillers, which is applied to the wheel rim, the chassis of agricultural machinery, agricultural machinery and machinery, etc. It can solve the problems of poor reliability, the rearward shift of the center of gravity of the whole machine, and the weight of the rear of the whole machine, so as to prevent deformation or Effects of damage, increase in effective width, and ease of assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

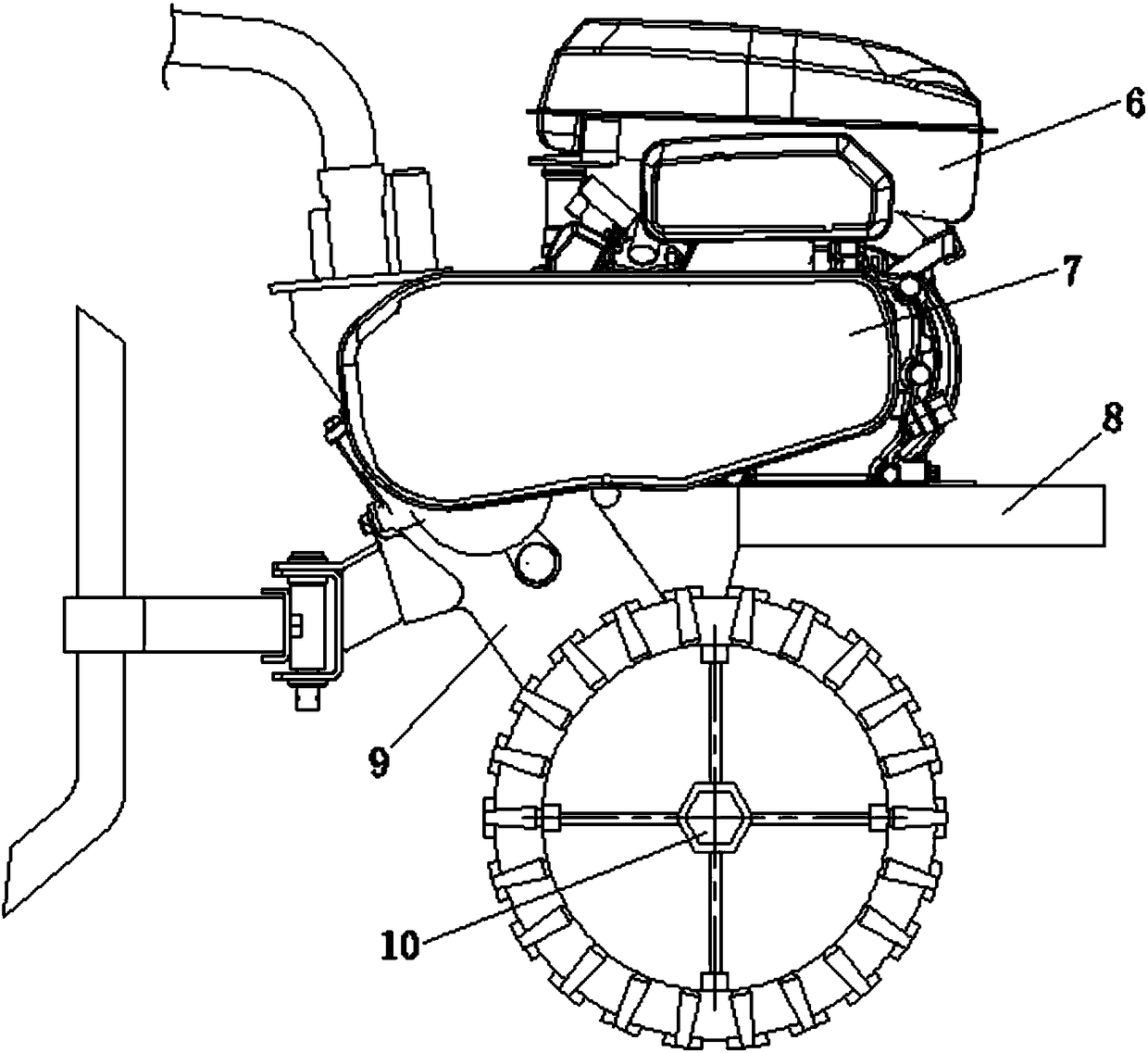

[0028] like figure 1 , figure 2 Shown, the motor 6 of tiller is positioned at the middle part of frame 8, and the bottom end of this motor 6 is fixed with frame 8, and the output end of motor 6 is connected with the driving wheel of belt transmission mechanism 7, and the driving wheel of belt transmission mechanism 7 After the front driven wheel, the driven wheel of this belt transmission mechanism 7 is connected with the input end of the gear box 9 . The gear box 9 is set with a low front and a high rear, and the angle between the gear box 9 and the ground is 53-58°. The output end of gear box 9 is connected with the middle part of wheel shaft 10, and the center of wheel shaft 10 is positioned at engine 6 directly below, and road wheel is installed at the two ends of wheel shaft 10.

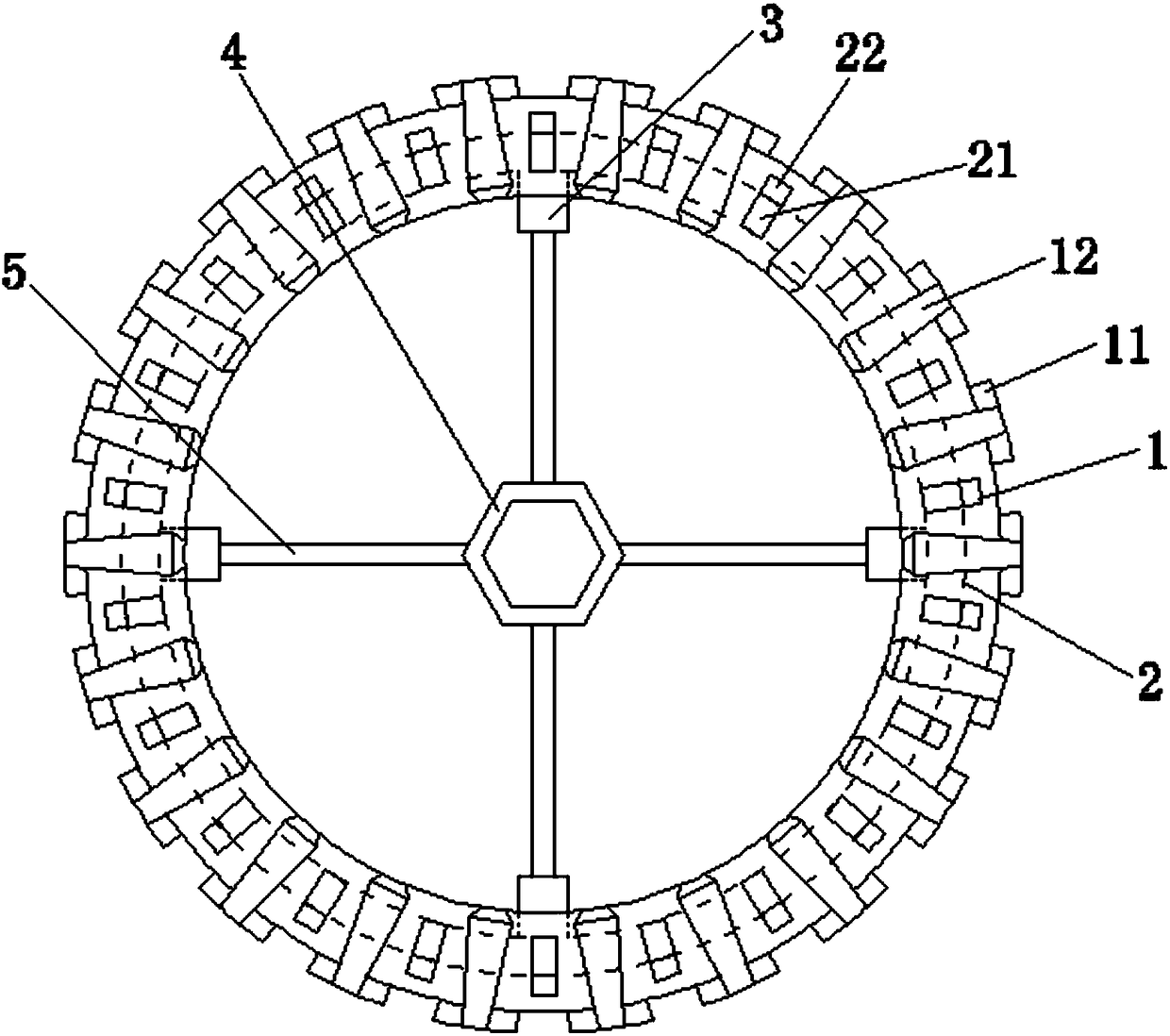

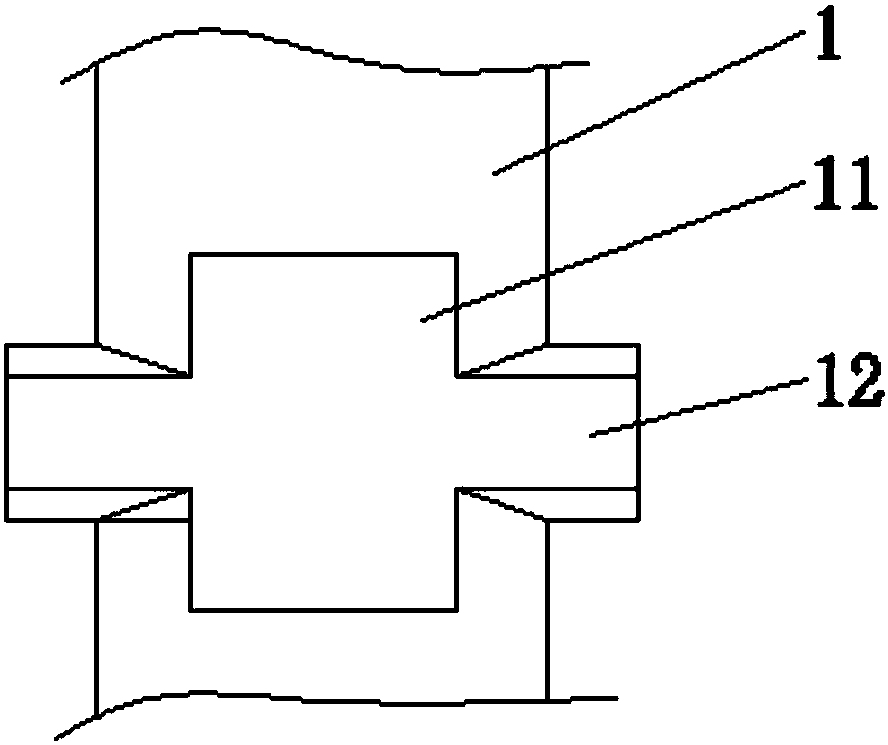

[0029] like figure 1 , figure 2 , image 3 As shown, the road whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com