Novel power tube device

A power pipe and a new type of technology, applied in the field of new power pipe devices, can solve the problems of limited clamping and fixing force, influence on the quality of the threading, poor fixing effect, etc., and achieve the effects of convenience and accuracy, improving threading efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

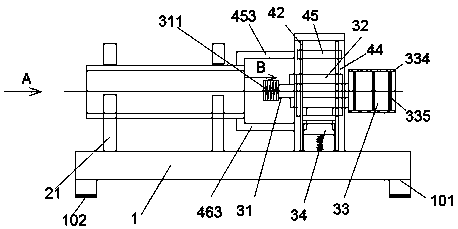

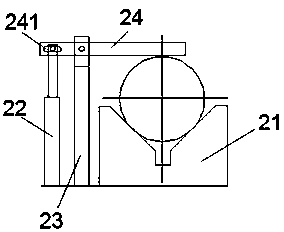

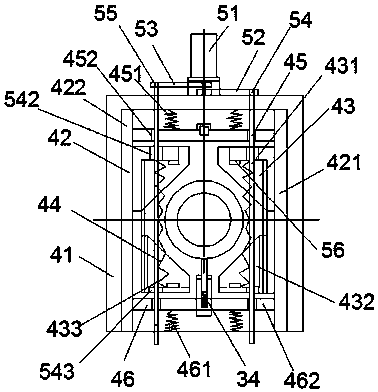

[0026] Such as Figure 1-Figure 8 As shown, a new type of power pipe device of the present invention includes a mounting frame 1, a setting part, a threading part and a clamping part, the setting part is fixed on the upper surface of the mounting frame 1, and the threading part is installed on The middle end of the clamping part, the clamping part is installed on the upper surface of the mounting frame on the right side of the placement part and can slide in the left and right direction, the bottom of the mounting frame 1 is provided with a supporting angle 101, each of the The bottoms of the supporting angles 101 are equipped with anti-slip pads 102, which can effectively prevent the phenomenon of unstable support caused by slipping due to wet and slippery ground, thereby improving the stability during support. The threaded part includes a support sleeve 32, The rotating pin shaft 31, the first motor 33 and the support seat assembly 34, the support seat assembly 34 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com