Method for estimating defect degree of carbon fiber surface based on region growing algorithm

A technology of regional growth and carbon fiber, which is applied in the estimation of surface defects of carbon fiber materials, which can solve the problems of easy loss of boundary information and excessive segmentation, and achieve the effect of assisting the evaluation of the quality of carbon fiber materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with specific embodiments.

[0064] refer to figure 1 , 3 , the implementation process of the inventive method is as follows:

[0065] A method for estimating the degree of defect on the carbon fiber surface based on the region growth algorithm, comprising the following steps:

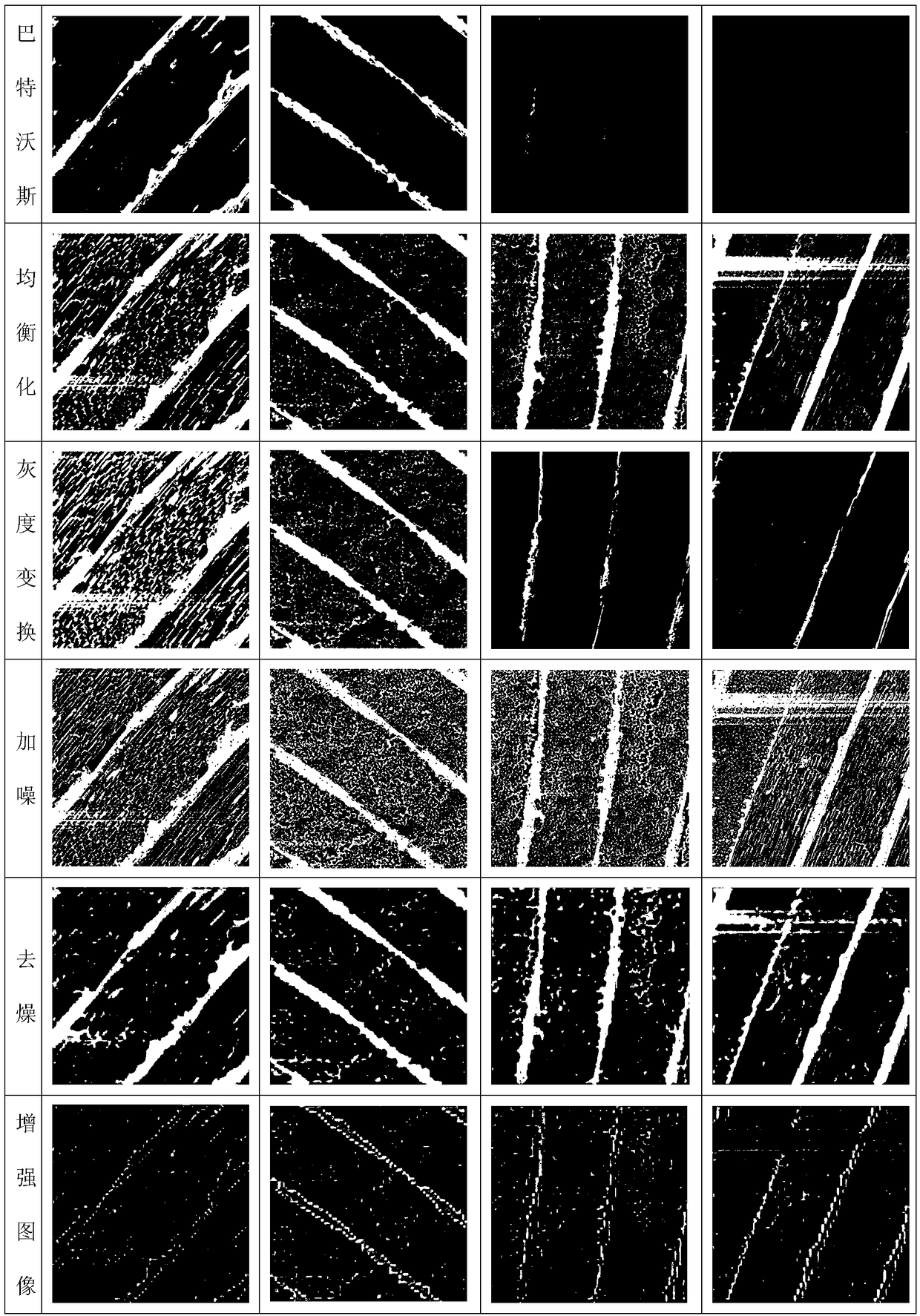

[0066] A, SEM image of the surface of the carbon fiber composite material taken with an electron microscope at 500 times. Preliminary image preprocessing is performed on a given SEM image of a carbon fiber surface containing a defect area. Image preprocessing includes image filtering, image grayscale transformation, image histogram averaging, image enhancement, and the final output required The preprocessed image after image enhancement; all subsequent experimental images are derived from the image preprocessed image here;

[0067] B. Extract the ROI area on the surface of the carbon fiber material, in order to better sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com