Toilet flushing method

A technology of toilet and water floating bucket, which is applied in the field of bathroom, can solve the problems of poor flushing effect and failure to flush the inner wall of the urinal in time, and achieve the effect of ingenious design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

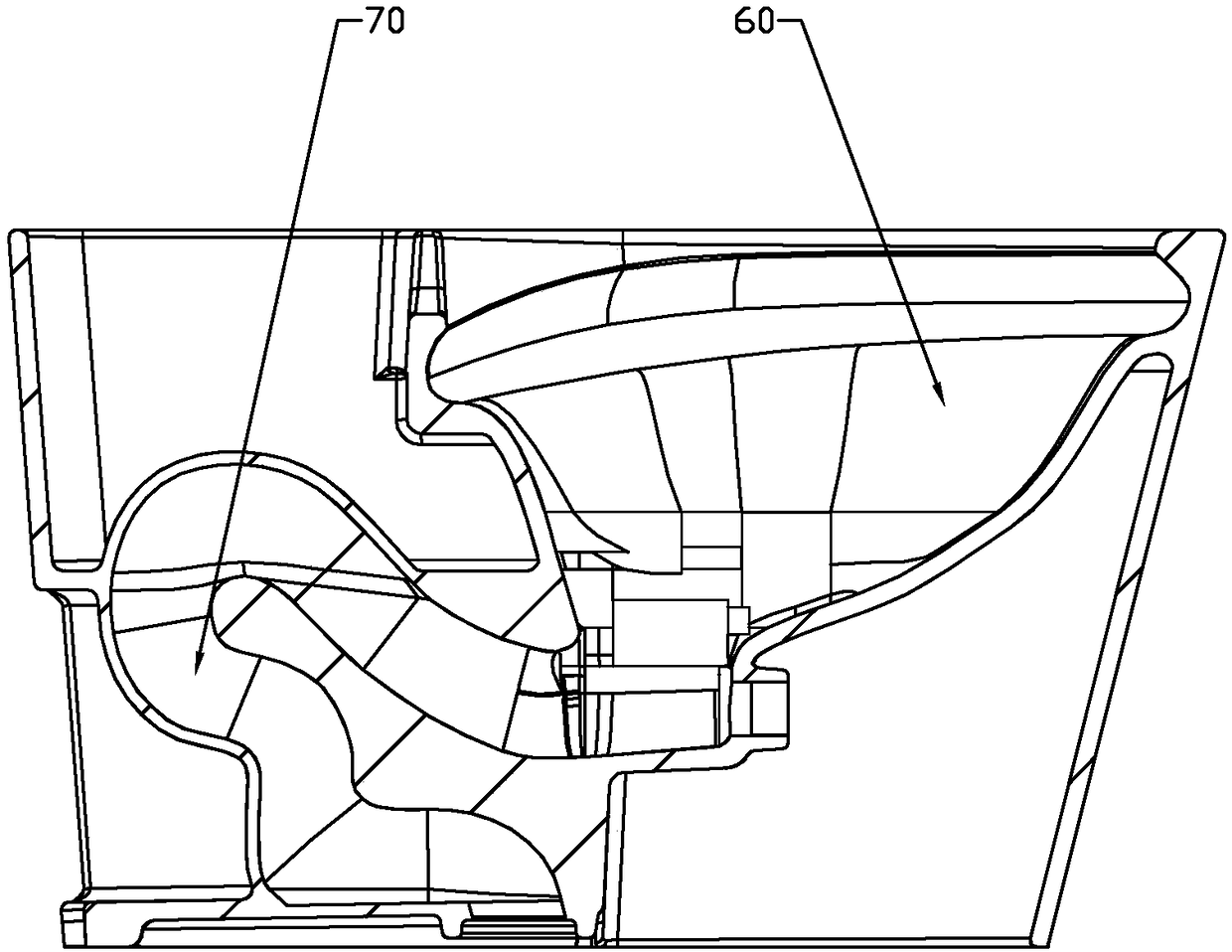

Image

Examples

no. 1 example

[0047] The first embodiment (integrated structure of water inlet mechanism and drainage mechanism):

[0048] like Figures 7 to 9 As shown, in this embodiment, the water inlet mechanism 10 and the drainage mechanism 20 are fixedly assembled into one body. Specifically, the water inlet mechanism 10 is fixedly attached to the drainage mechanism 20 so that the water inlet The mechanism 10 is connected with the drainage mechanism 20 as a whole to form an integrated inlet and drainage valve. The water inlet mechanism 10 is fixed on the drainage mechanism 20 through the upper cover and the casing, and the drainage mechanism 20 is mainly arranged in the casing. , the water tank water outlet 23 is arranged on the drainage base 22 .

[0049] In this embodiment, the water stop assembly 11 , the seal assembly 21 and the starting mechanism 30 are linked together; The starting mechanism 30 drives the water stop assembly 11 and / or the sealing assembly 21. In this embodiment, the starting ...

no. 2 example

[0057] Second embodiment (water inlet mechanism and drainage mechanism are split structures):

[0058] like Figure 10 and Figure 11 As shown, the water inlet mechanism 10 and the drainage mechanism 20 can be independently set up respectively, and an activation mechanism 30 can be used to directly and independently control the water stop assembly 11 and the sealing assembly 21; The activation mechanism 30 includes a water intake activation mechanism 10 and a drainage activation mechanism 20. The water intake activation mechanism 10 and the drainage activation mechanism 20 respectively drive the water stop assembly 11 and the sealing assembly 21, respectively. The mechanism 10 and the drainage activation mechanism 20 operate to realize the timing when the sealing assembly 21 and the water stop assembly 11 are driven. The water outlet channel 18; alternatively, the water inlet starting mechanism 10 and the drainage starting mechanism 20 are driven at the same time, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com