A color card printing mold for an automatic color card printing machine and a manufacturing method thereof

A production method and technology of a jet printer, which are applied in the photoengraving process, printing, printing device and other directions of the pattern surface, can solve the problem of low precision and difficulty in jet printing multiple color blocks of different colors at the same time. problem, to achieve the effect of accurate position, saving printing man-hours, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

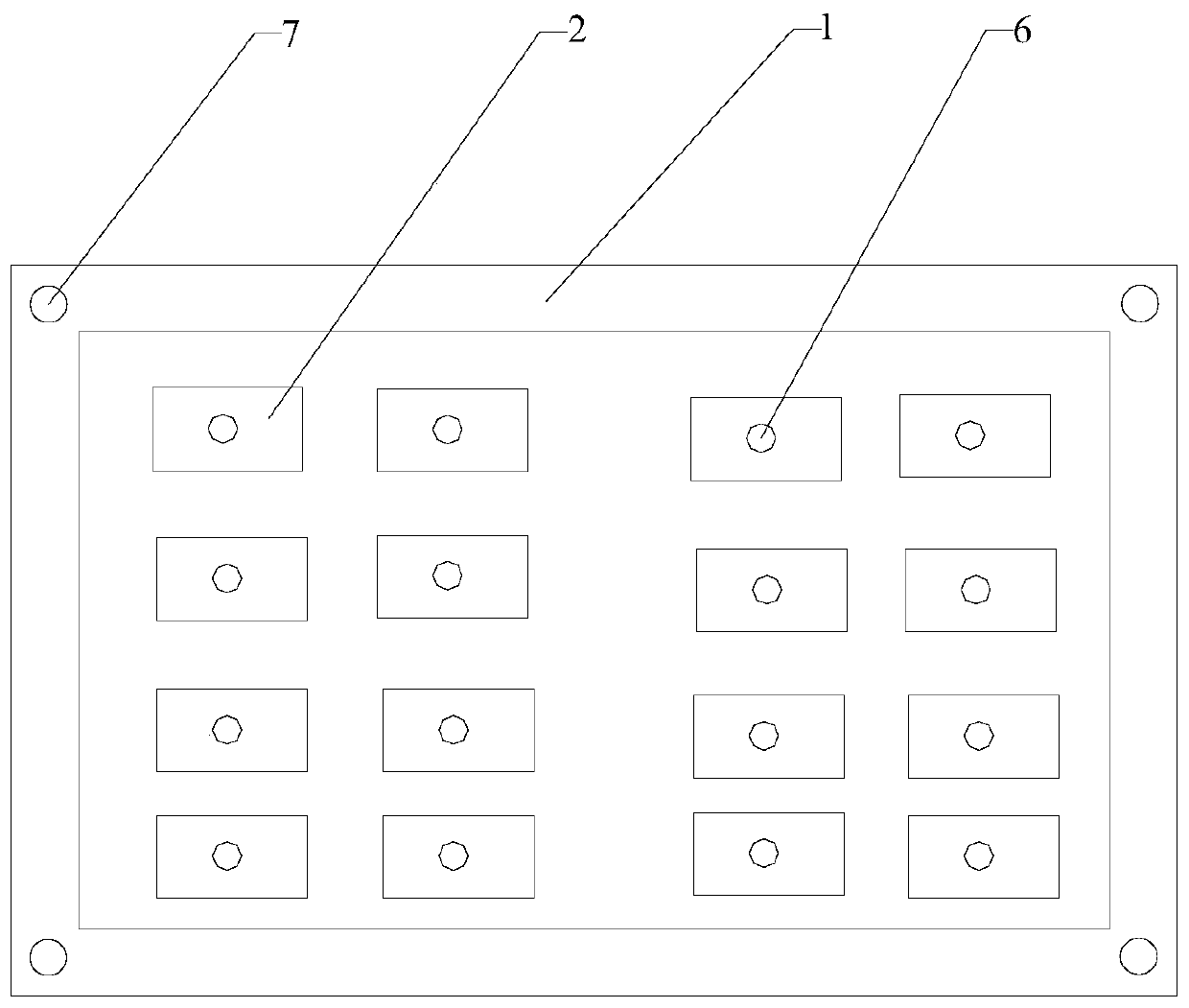

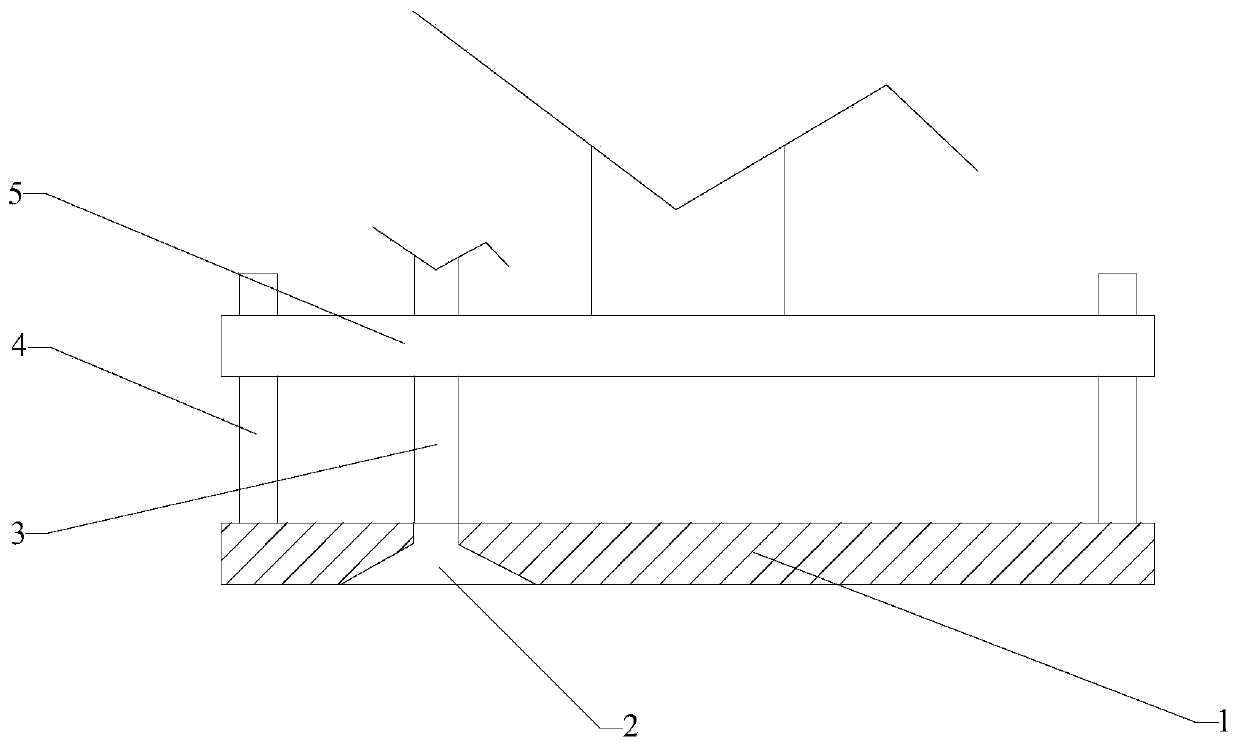

[0059] A color card spray printing mold for an automatic color card spray printer, comprising a mold body, a connector 4 and a spray printing conduit 3; the mold body is a rectangular zinc plate 1, and the lower part of the mold body is provided with a plurality of Groove 2, the middle part of the groove 2 is pierced with a first threaded through hole 6; the outside of the connecting end of the spray printing conduit 3 is provided with threads, and the spray printing conduit 3 is threadedly connected with the first threaded through hole 6 , the spray printing conduit 3 is connected to the upper part of the mold body; the four corners of the mold body are respectively provided with connectors 4, and the connectors 4 are used to fix the mold body on the lower part of the platen 5 of the color card automatic inkjet printer; The spray printing conduit 3 is a circular straight pipe made of stainless steel; the connector 4 includes bolts, and the four corners of the mold body are res...

Embodiment 2

[0061] A method for manufacturing a color card jet printing mold for an automatic color card jet printer, specifically comprising the following steps:

[0062] S1: Clean up the impurities in the lower part of the rectangular zinc plate 1 and blow dry;

[0063] S2: Spray photoresist on the lower part of the rectangular zinc plate 1 and dry it; the drying temperature is 80°C; cover the lower part of the dried rectangular zinc plate 1 with film, and the film is light-painted with Graphics of groove 2 shape;

[0064] S3: Place the rectangular zinc plate 1 covered with film on the printing machine for printing, and the printing time is 10 seconds;

[0065] S4: Place the rectangular zinc plate 1 after printing in the developing solution. After the rectangular zinc plate displays an image, wash it with clean water and dry it, and dry it in the sun for 10 minutes; the developing solution is composed of the developing solution and Clear water is configured according to the ratio of 1...

Embodiment 3

[0071] A method for manufacturing a color card jet printing mold for an automatic color card jet printer, specifically comprising the following steps:

[0072] S1: Clean up the impurities in the lower part of the rectangular zinc plate 1 and blow dry;

[0073] S2: Spray photoresist on the lower part of the rectangular zinc plate 1 and dry it; the drying temperature is 80°C; cover the lower part of the dried rectangular zinc plate 1 with film, and the film is light-painted with Graphics of groove 2 shape;

[0074] S3: Place the rectangular zinc plate 1 covered with film on the printing machine for printing, and the printing time is 360 seconds;

[0075] S4: Place the rectangular zinc plate 1 after printing in the developing solution. After the rectangular zinc plate displays an image, wash it with clean water and dry it, and dry it in the sun for 20 minutes; the developing solution is composed of the developing solution and Clear water is configured according to the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com