Microchannel reactor applicable to dehydrogenation reaction of liquid hydrogen source materials and dehydrogenation method

A technology of microchannel reactor and source material, applied in the field of microchannel reactor and dehydrogenation, can solve the problems of uneven heating, difficulty in reactor amplification, poor heat transfer, etc. The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

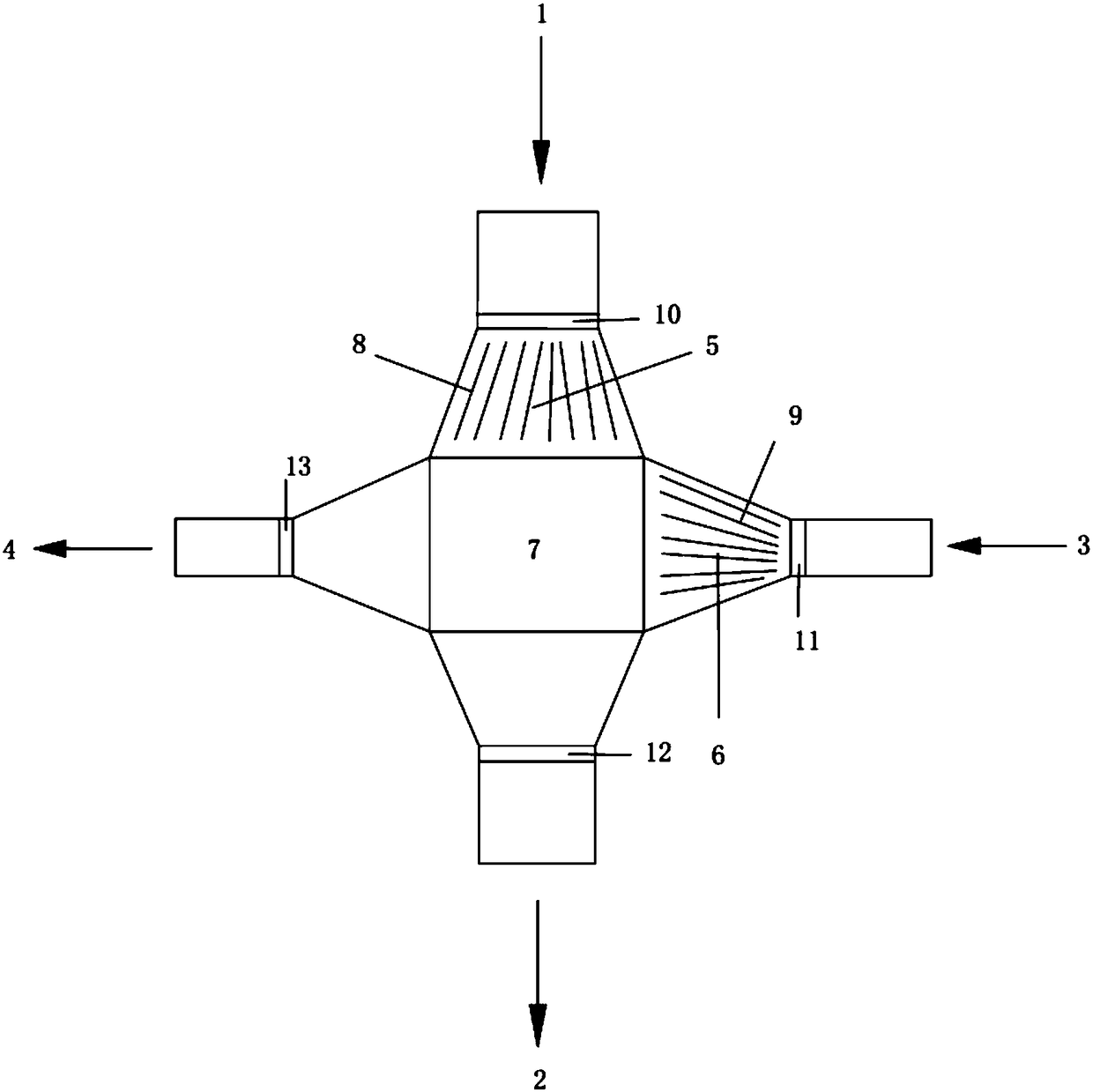

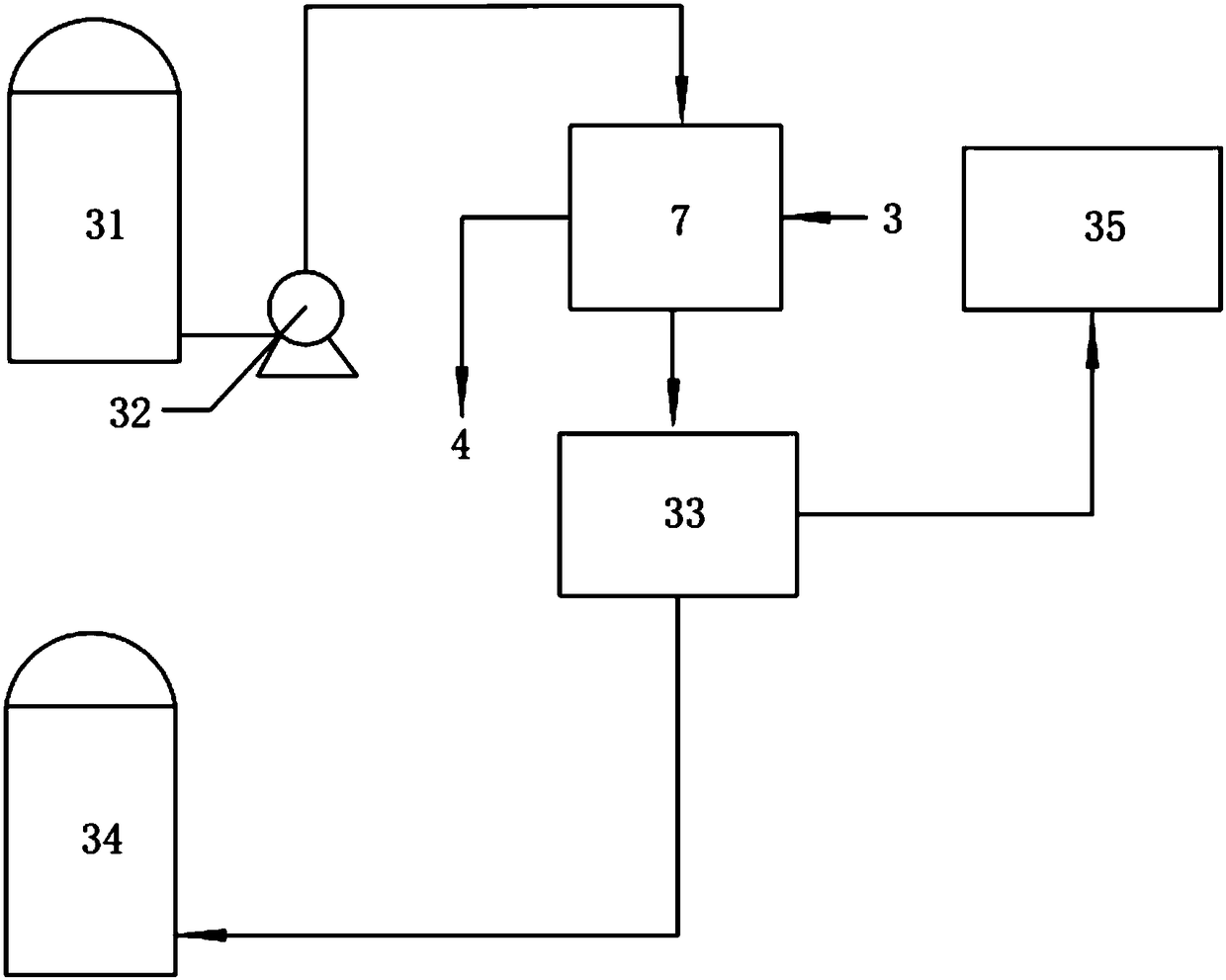

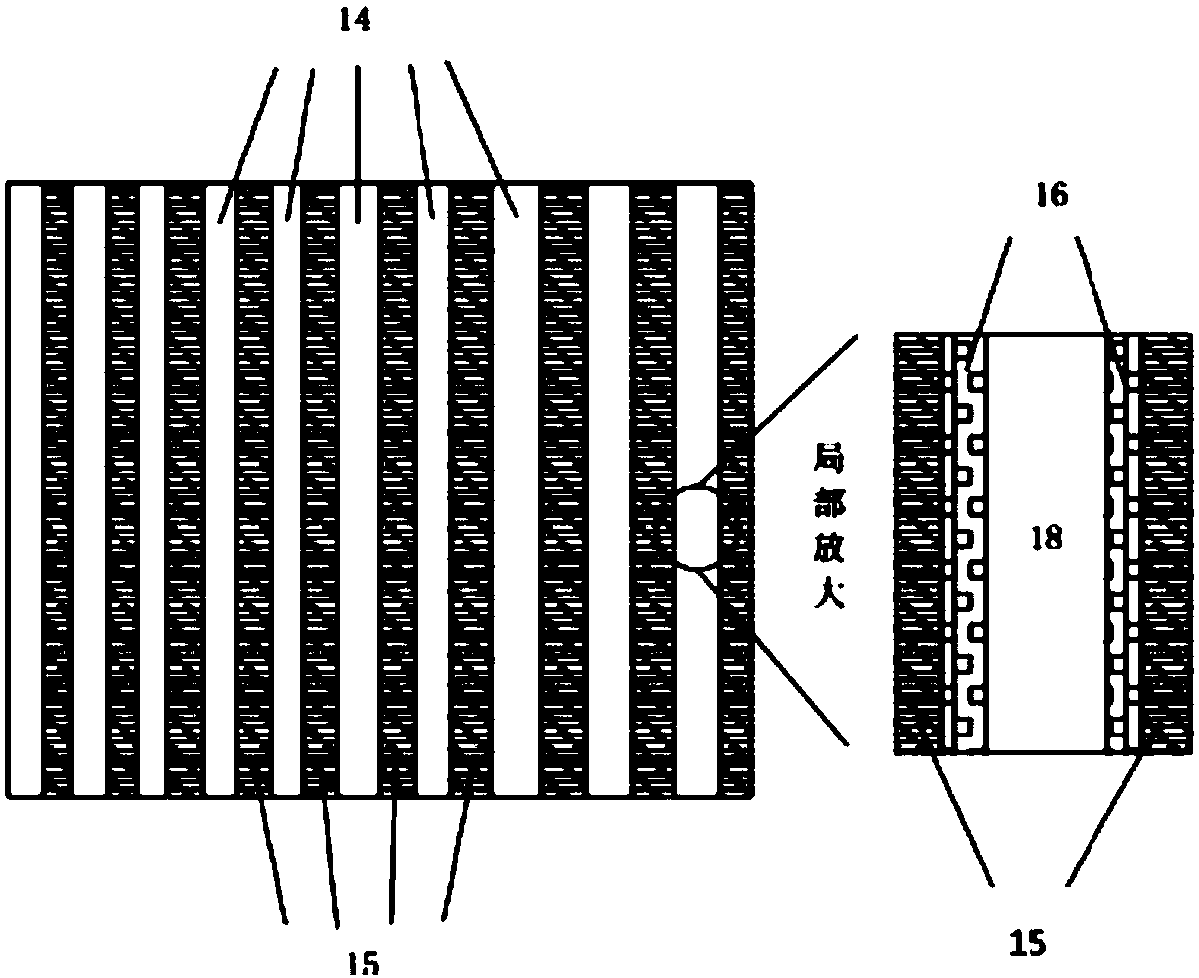

[0033] Such as figure 1 As shown, a microchannel reactor suitable for the dehydrogenation reaction of liquid hydrogen source materials, a liquid distributor 5 is connected above the microchannel reactor body 7, and a deflector 8 is arranged inside the liquid distributor 5, and the liquid A high-temperature flange 10 is provided between the distributor 5 and the hydrogen source material inlet 1, and the hydrogen source material inlet 1 is connected to the liquid hydrogen source material storage tank 31 through a delivery pump 32, such as figure 2 As shown, the outlet 2 of hydrogen storage carrier and hydrogen is arranged below the microchannel reactor body 7, and a high-temperature flange 12 is arranged between the microchannel reactor body 7 and the outlet 2; the inlet side of the microchannel reactor body 7 is connected with Heat carrier distributor 6, the inside of heat carrier distributor 6 is provided with deflector 9, is provided with high temperature flange 11 between h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com