Transformer drying system

A technology of drying system and transformer, applied in the field of drying system, can solve the problems of energy waste, non-compliance with energy saving and emission reduction, and achieve the effect of optimizing the structure of power consumption and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

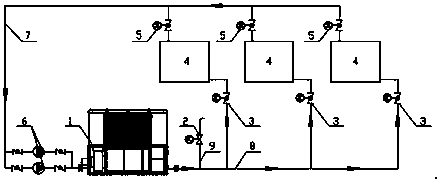

[0017] The following combination figure 1 , the technical content, structural features, achieved goals and effects of the present invention will be described in detail through preferred embodiments.

[0018] Such as figure 1 As shown, the transformer drying system provided by the present invention includes: a heat storage device 1, which has an air inlet and an air outlet, and stores heat during the low-peak power consumption period; The air inlet of the device 1 is connected; multiple transformer drying rooms 4 are placed inside to place the transformers to be dried; each transformer drying room 4 is respectively connected to the air outlet of the heat storage device 1 through the air duct system, and connected to each induced draft fan 6 ; Wherein, the heat storage device 1, the induced draft fan 6 and the transformer drying room 4 form a thermal cycle loop through the air duct system; during the peak power consumption period, the circulating air circulating in the air duct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com