Long-distance horizontal directional drilling and grouting reinforcement technology of water-rich sand layer under building group

A water-rich sand layer and horizontal orientation technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the problems of difficult hole layout, narrow construction space, limited reinforcement range, etc., and avoid demolition Resettlement costs, wide range of sources, good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

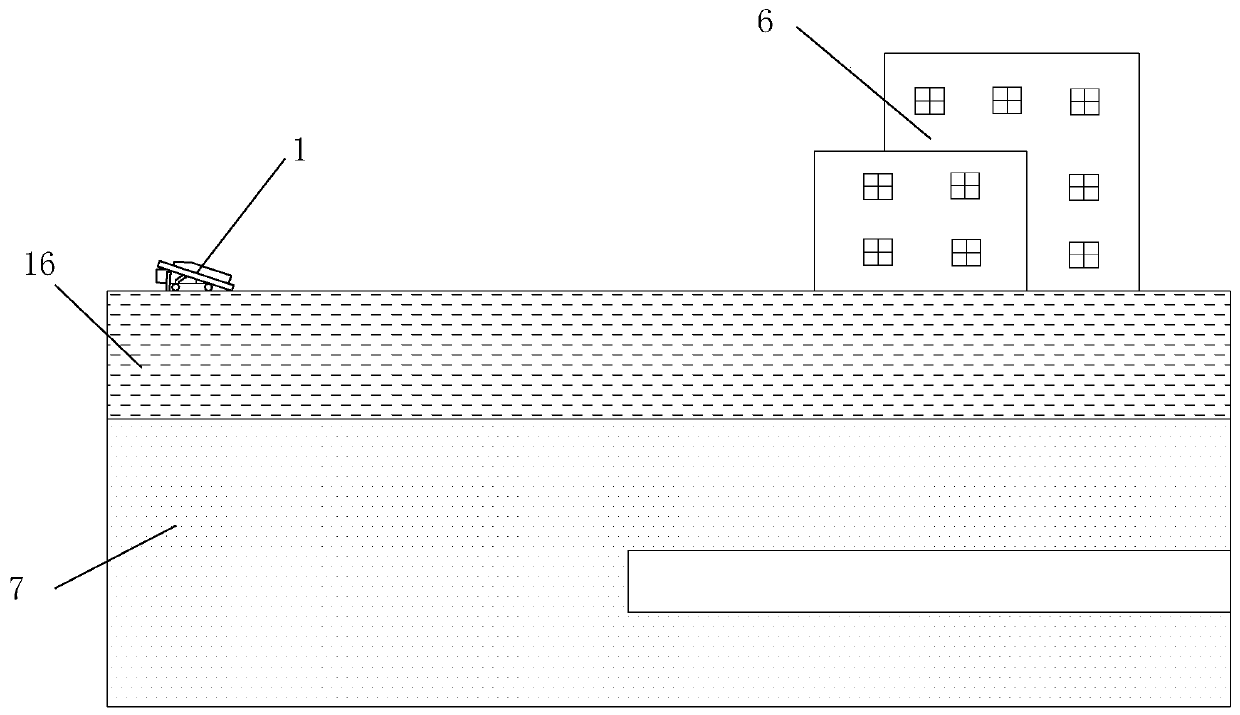

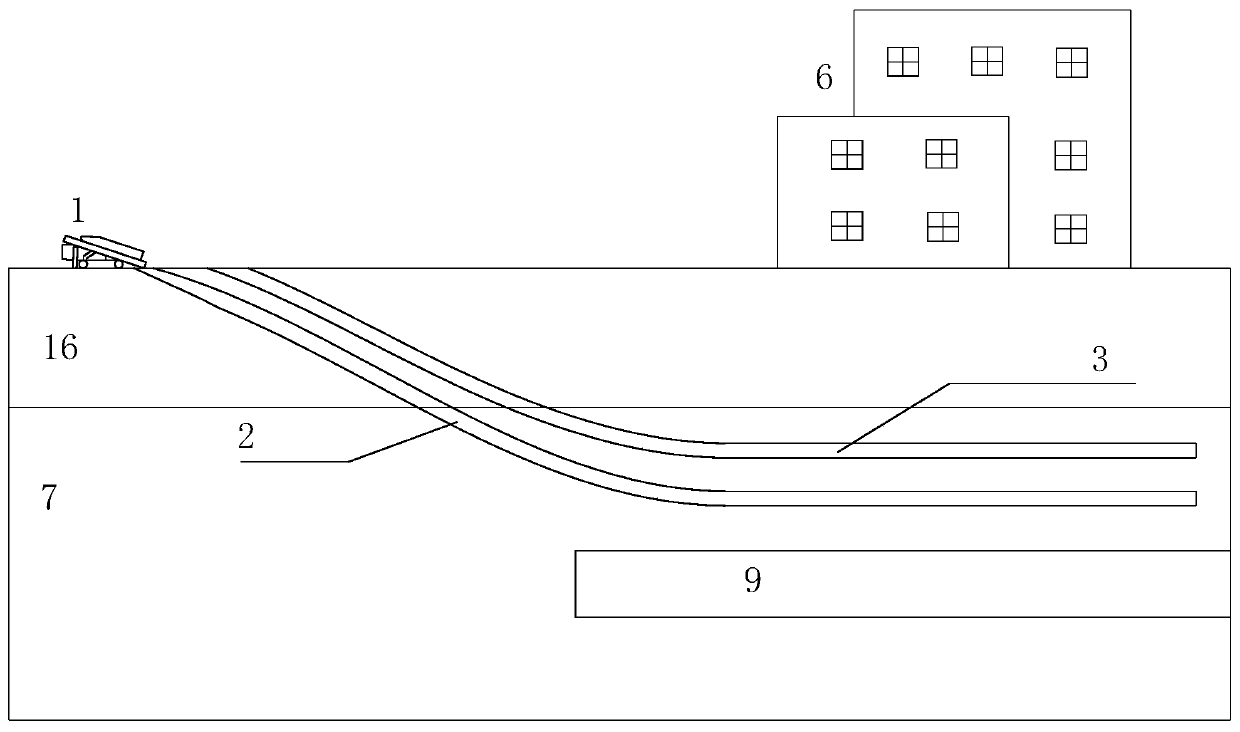

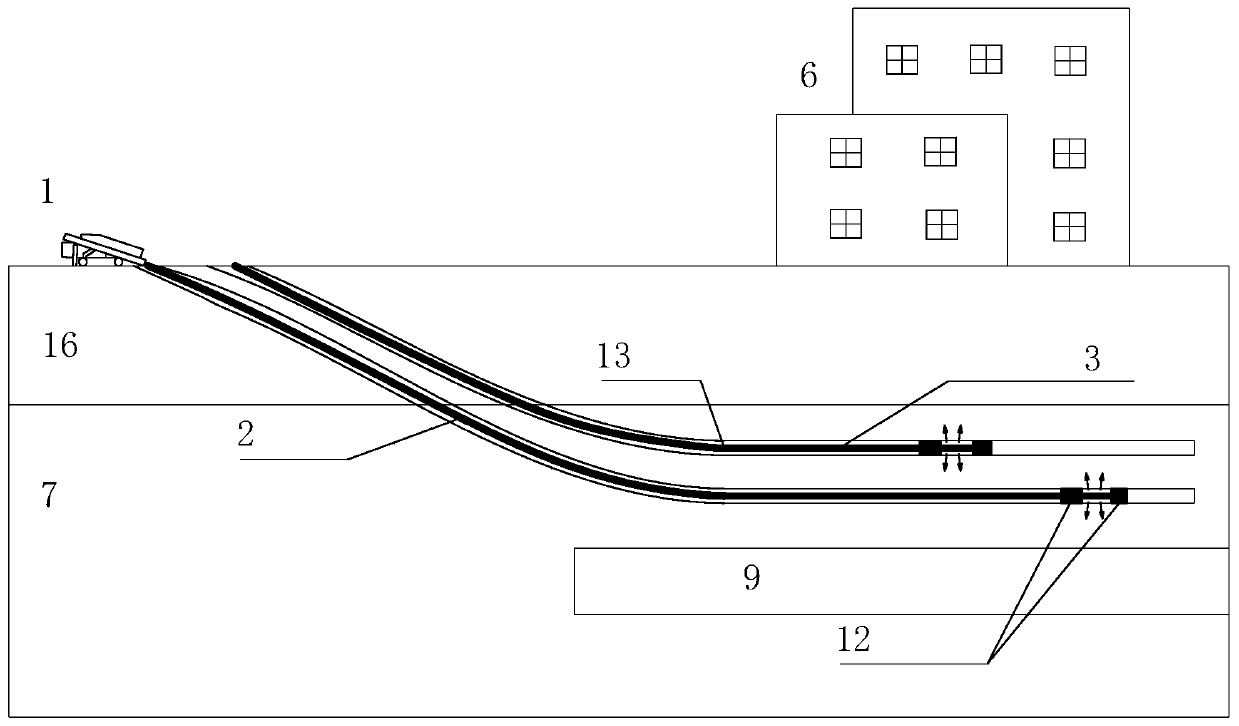

[0037] like Figure 1 to Figure 6 As shown, the long-distance horizontal directional drilling and grouting reinforcement technology of the water-rich sand layer under the building group in this embodiment was tested in the first phase construction project of Guangzhou Rail Transit Line 14 from Dengcun to Jiangpu Station surnamed Zhongwei building group , which specifically includes the following steps:

[0038] (a) if figure 2 As shown, the deviated well steerable drilling rig 1 is used on the ground to form a grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com