Frequency rising method for magnetic valve of quenching machine

A solenoid valve and quenching machine technology, which is applied in the field of quenching machines, can solve the problems of long water stabilization time and slow opening speed of quenching machine solenoid valves, so as to solve the waste of energy consumption, shorten the time for frequency-up stabilization, and increase the rhythm of steel installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

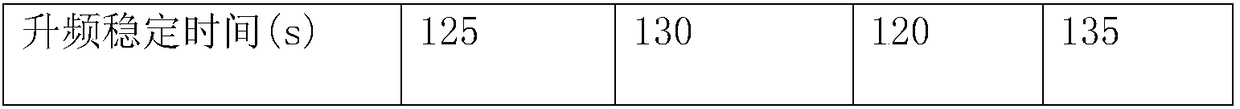

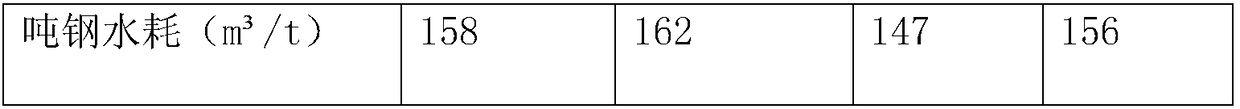

[0009] This embodiment is a method for increasing the frequency of the solenoid valve of the quenching machine. The quenching machine is a roller quenching machine, which is suitable for the treatment of the solenoid valve of the quenching machine with long time and stable water volume. The relationship between the frequency increase time and the water consumption per ton of steel is shown in the table:

[0010]

[0011]

[0012] It can be seen from the above table that when the frequency of the quenching machine is increased, the valves are opened one by one, and there is a stabilization time. The current stabilization time exceeds 100S, and the longer the frequency increase time, the more serious the water waste. This embodiment starts with reducing the frequency-up stabilization time, so that the solenoid valve directly reaches the set value. Specifically: when the next steel plate is tapped, click the frequency increase on the quenching machine interface to quickly op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com