Milling machine waste collector

A technology for waste collection and milling machines, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

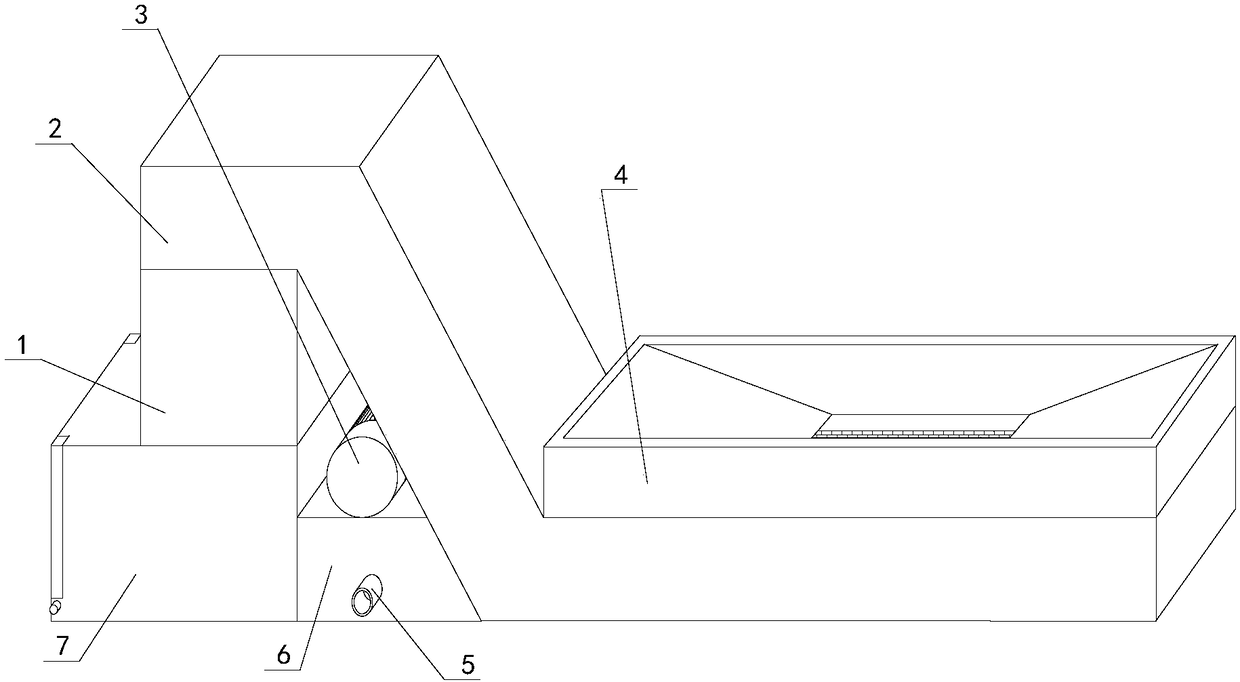

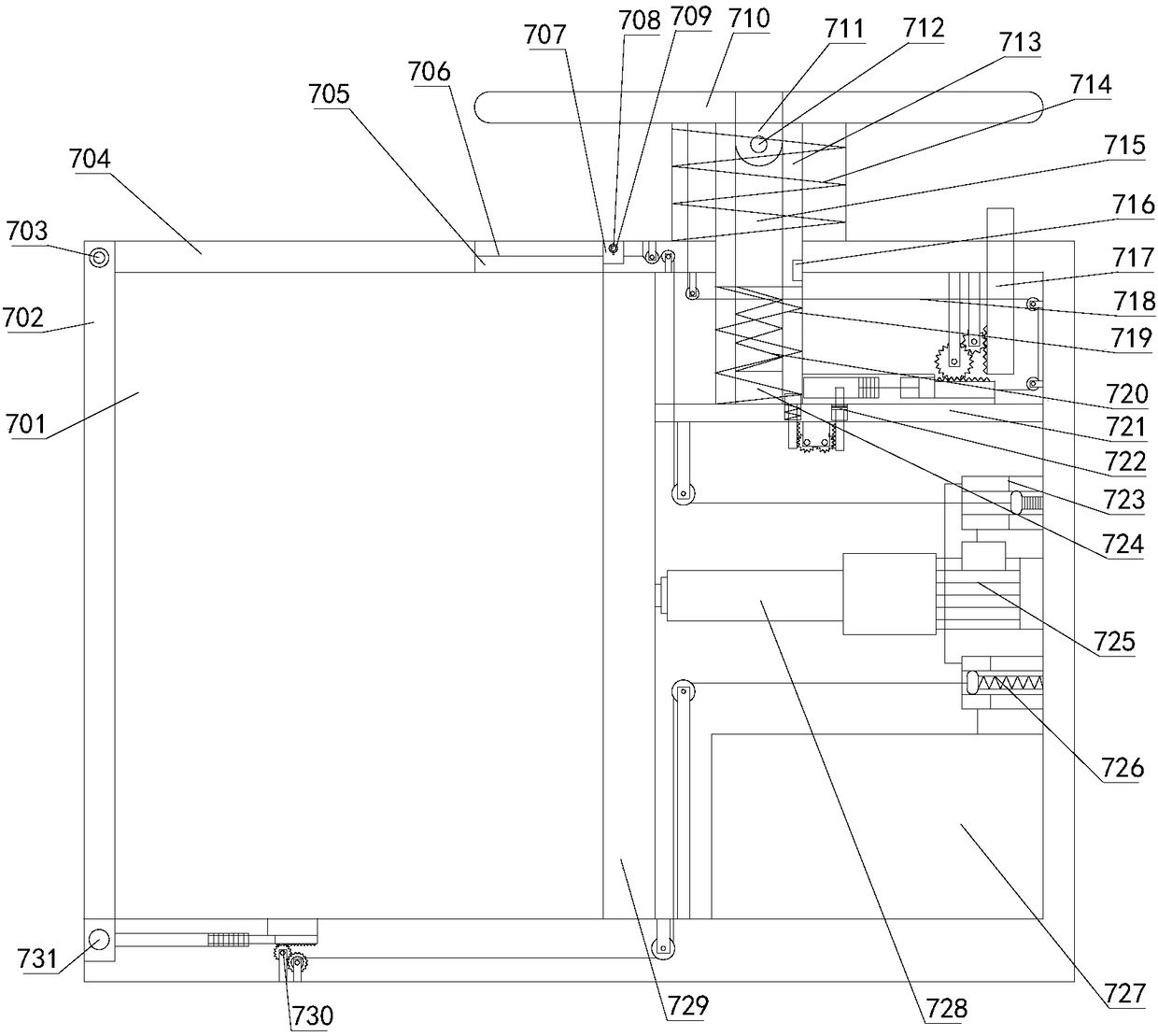

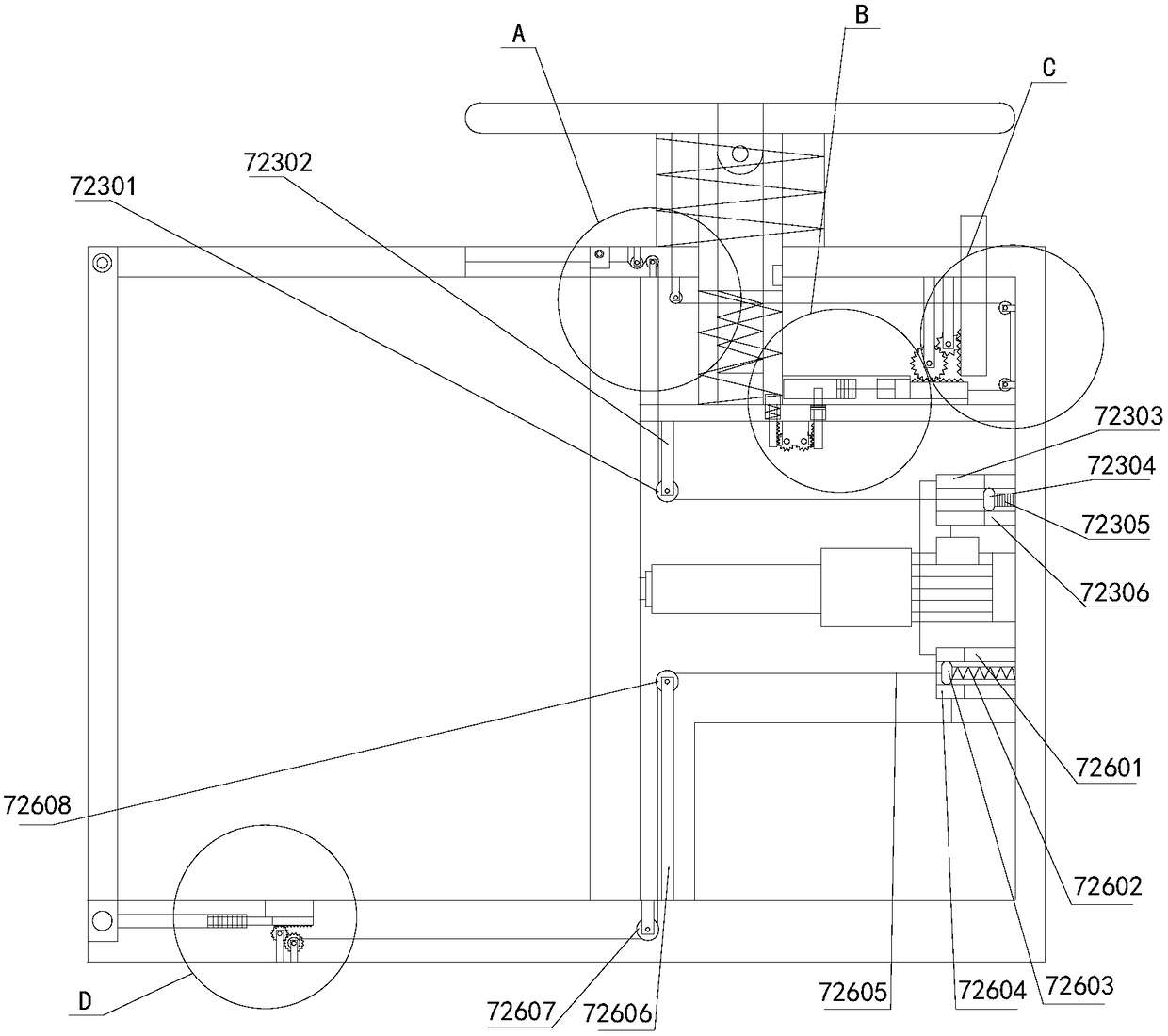

[0025] see Figure 1-Figure 7, the present invention provides a technical scheme of a milling machine waste collector: its structure includes a feeding groove 1, a lifter 2, an extraction motor 3, a collection seat 4, a liquid discharge port 5, an extraction seat 6, and a collection compression box 7. The lifter 2 is Z-shaped, a collecting seat 4 is welded on the right side of the top end, and a feeding receiving groove 1 is welded on the left side of the bottom end. The extraction seat 6 is locked and connected, the right end of the extraction seat 6 is welded with the lifter 2, and the extraction motor 3 is locked at the top. Box body 704, collecting and feeding port 705, feeding induction baffle 706, trigger assembly head 707, tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com