Backlight FPC board and backlight half-finished product

A backlight and backside technology, applied in the direction of electrically connecting printed components, non-printed electrical components connected printed circuits, printed circuit components, etc., can solve the problems of poor LED collinearity, LED lamp eyes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

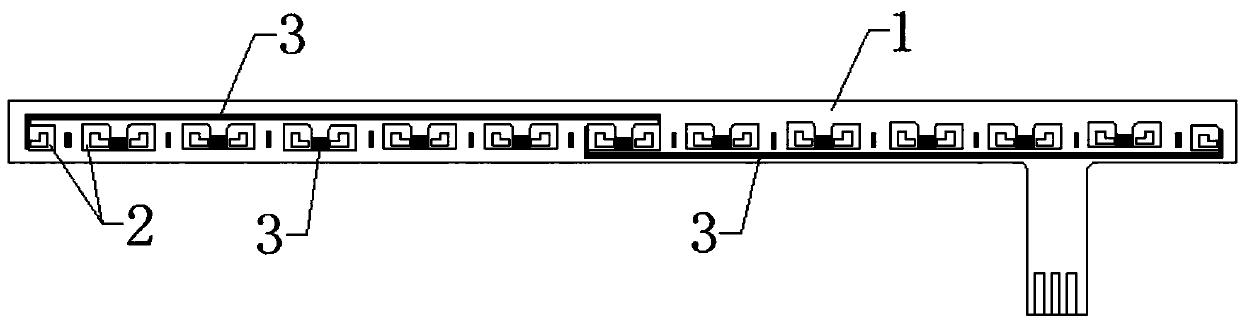

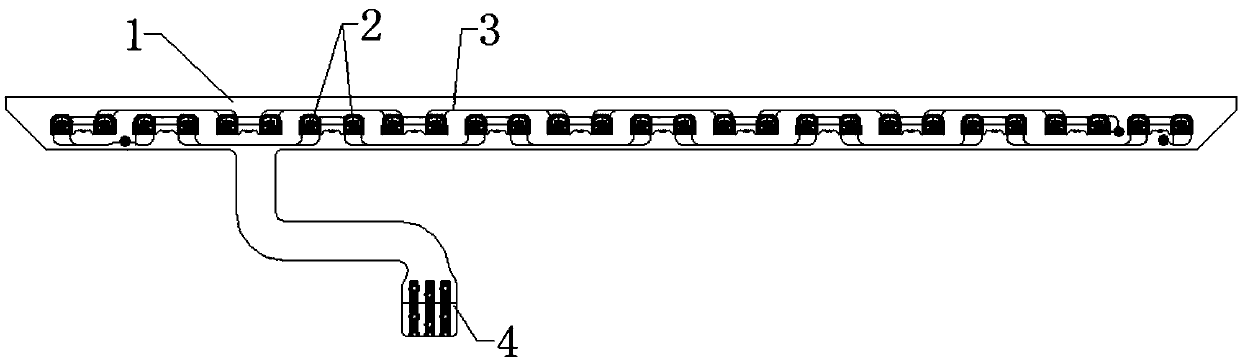

[0023] refer to figure 2 , is a schematic diagram of the back structure of the circuit layer of the backlight FPC board; combined image 3 , is a schematic diagram of the front structure of the circuit layer of the backlight FPC board; and Figure 4 and Figure 5 , the structural diagram of the backlight semi-finished product formed by adding LED components and light guide plates to the backlight FPC board.

[0024] like Figure 2 to Figure 5 As shown in , the backlight FPC board provided by the present invention includes an FPC board 1, and a plurality of groups of pads 2 arrayed on the back of the FPC board 1 along the length direction of the FPC board 1, wherein the pads 2 are connected to each other through a skip wiring process. Joined together, each group of pads 2 includes electrically connected A pole (i.e. anode, positive pole) and K pole (ie kathode, negative pole), and the skip wiring process is that the K pole of each pad 2 crosses the adjacent The pad 2 is co...

Embodiment 2

[0028] combine Figure 4 and Figure 5 , is a schematic diagram of the structure of the backlight semi-finished product formed by adding LED components and light guide plates to the backlight FPC board. The present invention also provides a backlight semi-finished product, including a light guide plate 6, an LED assembly 5 and the above-mentioned backlight FPC board 1, wherein the backlight FPC board 1 is horizontally connected to the lower end of the light guide plate 6, and the LED assembly 5 is pasted by an SMT patch process. It fits on the back of the backlight FPC board 1, and the solder paste is coated between the LED assembly 5 and the backlight FPC board 1. And the effect produced is the same as that achieved in the above-mentioned embodiment. Further, the front side of the backlight FPC board 1 is coated with white oil to form a white film layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com