Process equipment and control engineering comprehensive experiment system

An experimental system and control engineering technology, which is applied in boilers, centrifugal pump comprehensive experimental systems, heat exchangers, expanders, and compressors. Problems such as small adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

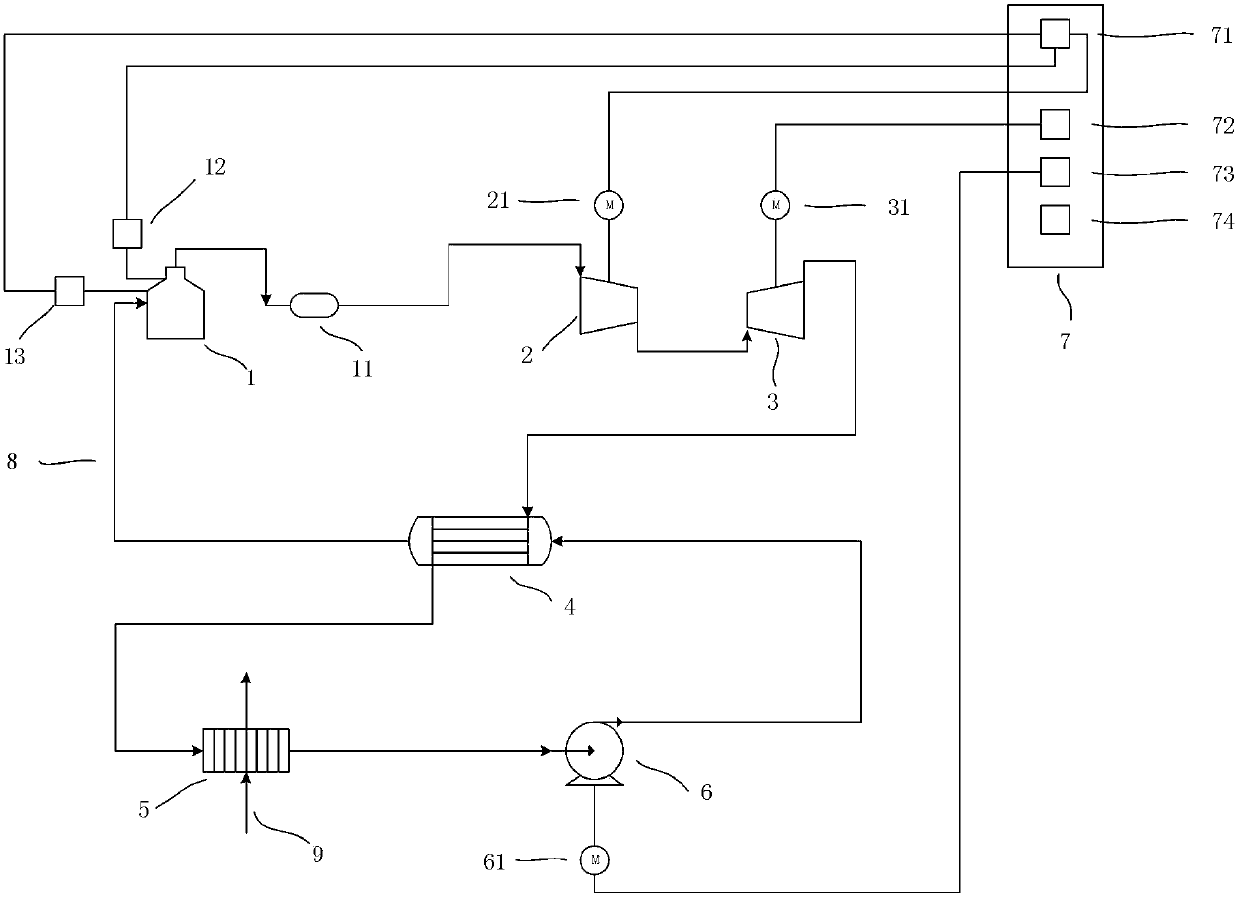

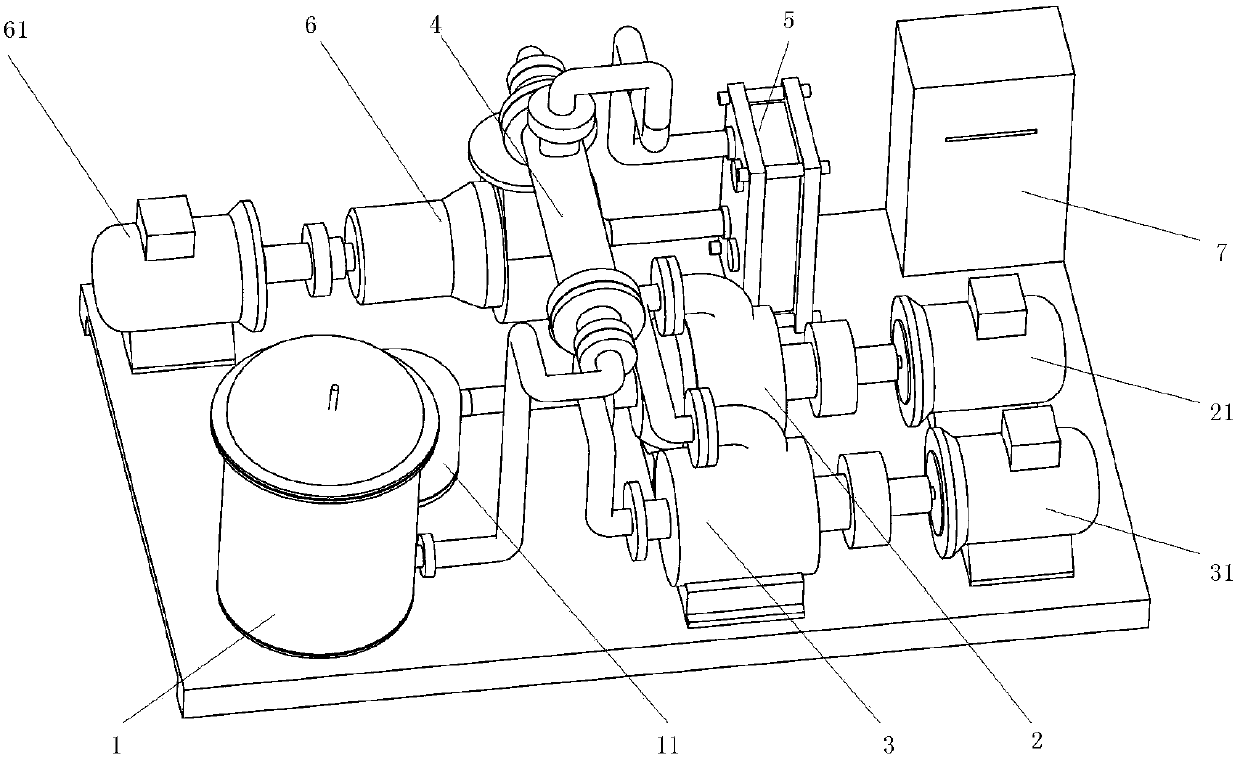

[0031] Attached below figure 1 Be explained:

[0032] Such as figure 1 As shown, a comprehensive experimental system for process equipment and control engineering, which is used for teaching and scientific research, includes a boiler 1, a steam drum 11, a measuring transmitter 12, an electric heater 13, a compressor 2, a compressor motor 21, Expander 3, expander generator 31, heat exchanger 4, condenser 5, centrifugal pump 6, centrifugal pump motor 61, control box 7, steam generation controller 71, expander generator signal receiver 72, centrifugal pump motor Speed controller 73 , display device 74 , circulating working medium 8 and condenser heat exchange medium 9 .

[0033] The boiler 1 is an electric heating boiler; the compressor 2 is a centrifugal compressor; the expander 3 is a turbo expander; the heat exchanger 4 is a shell-and-tube heat exchanger, and the The condenser 5 described is a finned air-cooled condenser.

[0034] The circulating working medium 8 is in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com