Bevel-angle self-locking spanner

A wrench and bevel technology, applied in the field of self-locking wrench with bevel angle, can solve the problems of time-consuming, laborious and low efficiency, and achieve the effect of wide applicability, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

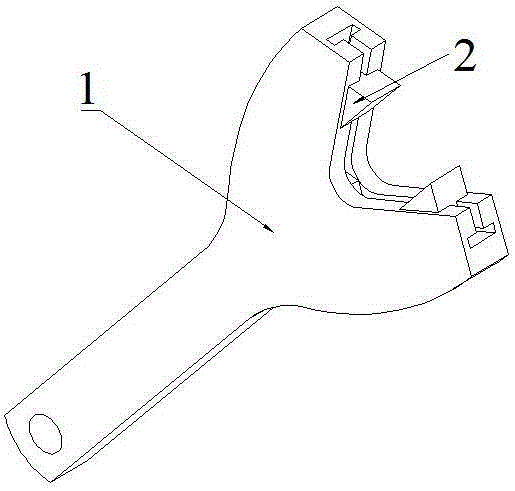

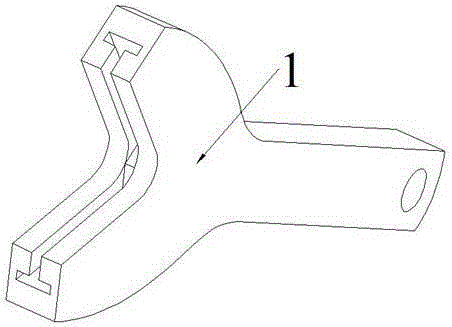

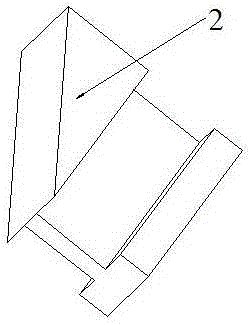

[0013] Such as figure 1 , 2 3. As shown in 3: self-locking wrench with inclined plane angle, its structure includes a wrench base and an adjustment slider; the wrench base has a Y-shaped structure, and the adjustment sliders are respectively located at the two front ends of the wrench base; the two front ends of the wrench base have a T-shaped slot respectively , The upper opening of the T-shaped slot goes directly to the front end of the wrench base; there is a T-shaped protrusion at the bottom of the adjustment slider, and the upper end of the adjustment slider has an inclined surface, and the inclined surface forms an angle of 30 degrees with the bottom surface of the T-shaped protrusion.

[0014] When in use, slide the two adjusting sliders along the T-shaped slot at the front end of the wrench base, and then clamp the bolt or nut to be rotated by the clamping action of the adjusting slider to the required position. The friction force between them makes the position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com