Low-adding hydrophobic heat energy reutilization device

A low-pressure heating and hydrophobic technology, applied in lighting and heating equipment, steam/steam condensers, etc., can solve the problems of connection pipeline vibration, heat energy waste, impact, etc., to achieve full thermal energy reuse, reduce vibration and impact, heat Exchange full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

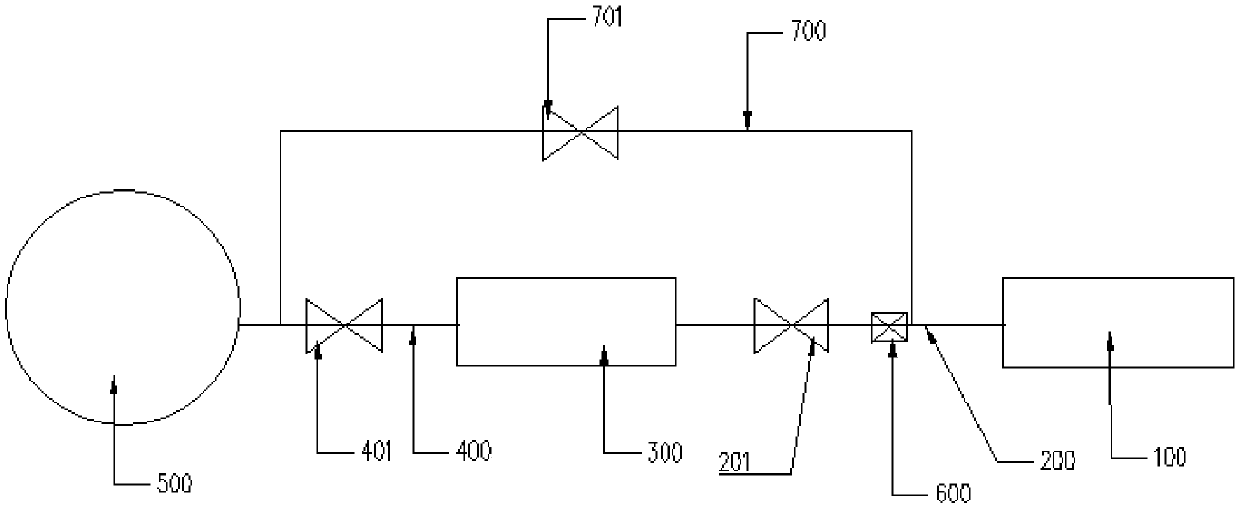

[0019] Such as figure 1 As shown, the low-pressure heating drain tank 100 communicates with the subcooler 300 through the first drain pipe 200 , and the subcooler 300 communicates with the condenser 500 through the second drain pipe 400 . Such a structural design makes the water in the water tank pass through the cooler 300 for heat exchange before entering the condenser 500, and the heat is recovered and reused by the condensed water, which realizes the reuse of heat energy and effectively improves the thermal efficiency of the system. And reduce the temperature of the water that enters the condenser 500, reduce the temperature difference between the water that enters the condenser 500 and the saturated water in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com