Electromagnetic drying chamber

A drying room, electromagnetic technology, applied in drying, dryer, drying gas layout and other directions, can solve the problems of low drying efficiency, lack of natural resources, waste of resources, etc., to achieve rapid heating process and high heat utilization rate , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

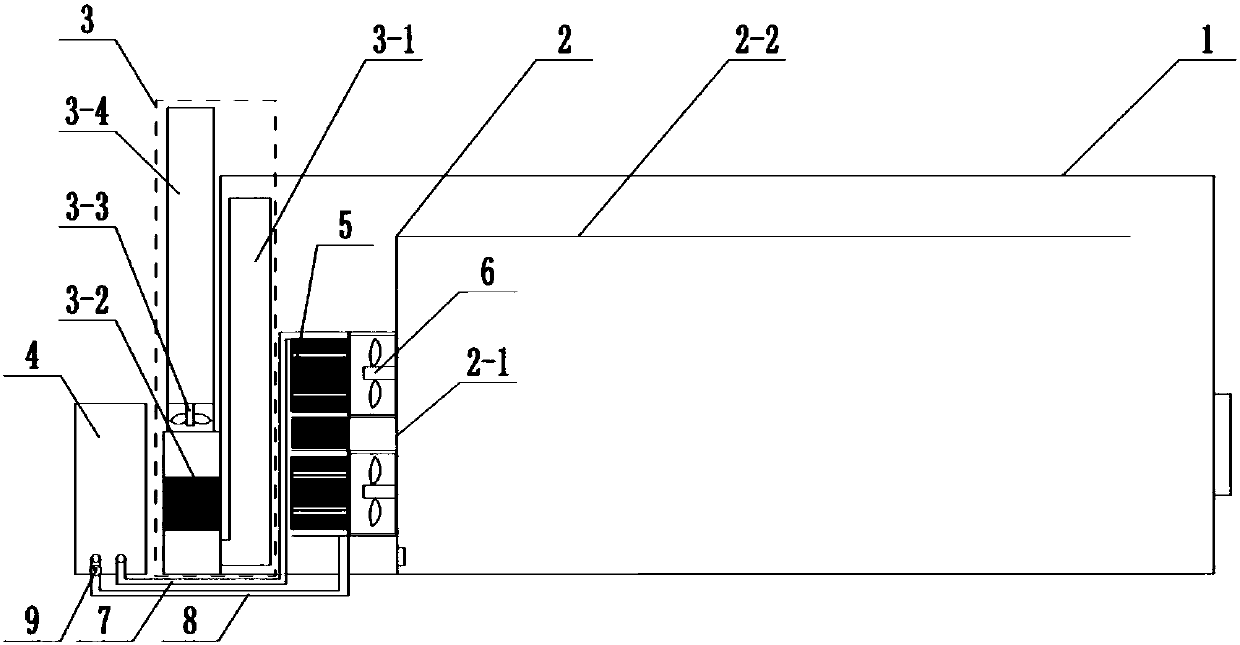

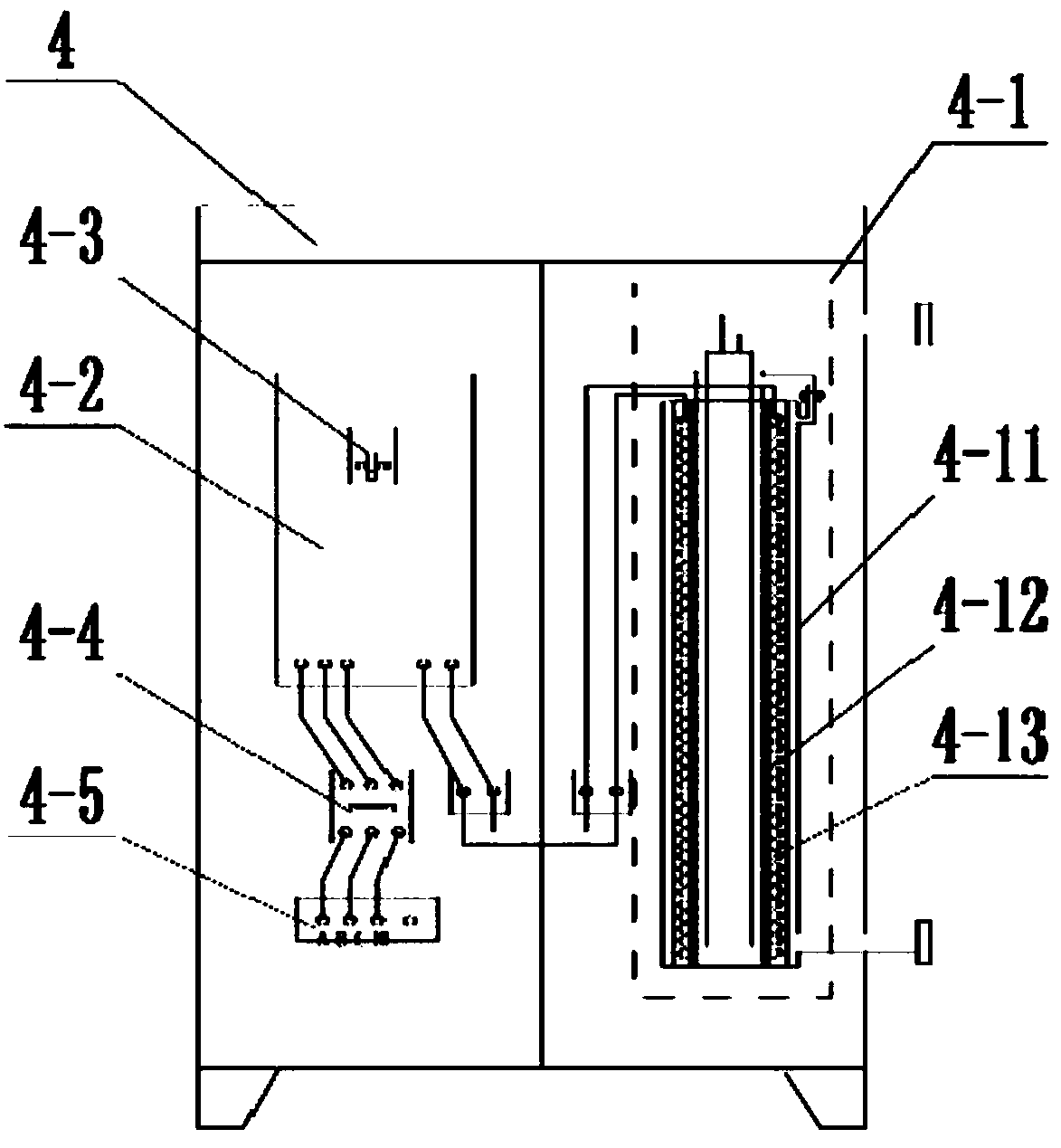

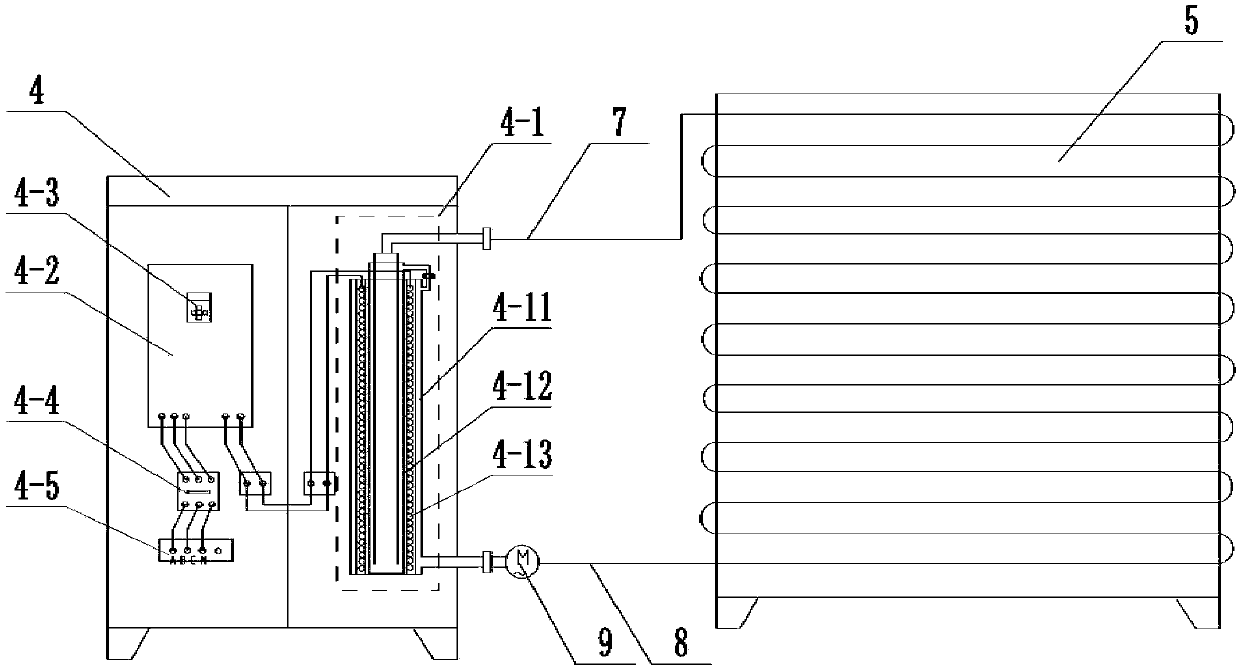

[0016] Such as Figure 1 to Figure 3 As shown, an electromagnetic drying chamber includes a chamber body 1, a partition 2, a moisture removal device 3, a heating device 4, a surface cooler 5, a high-temperature fan 6, a heat conduction pipe 7, a heat conduction pipe 8 and a circulation Pump 9; the chamber body 1 is a square cavity structure, the partition 2 is located inside the chamber body 1, the partition 2 includes a first partition 2-1 and a second partition 2-2 connected to each other, the first partition 2- 1 is vertically arranged, and one end of it is connected to the bottom of chamber body 1, and the other end leaves a gap with the top of chamber body 1; There are gaps on the side wall and the right side wall, the material of the chamber body 1 is polyurethane board, and the material of the partition board 2 is heat insulation board; the dehumidification device 3 includes the internal moisture pipe 3-1 and the heat exchanger 3-2 connected in sequence , dehumidificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com