Garbage incinerator with double grates

A technology of waste incinerator and incinerator, which is applied in the directions of grate, incinerator, combustion method, etc., can solve the problems of insufficient combustion, low incineration efficiency, uneven heating of waste, etc., to improve incineration efficiency, reduce incineration cost, good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

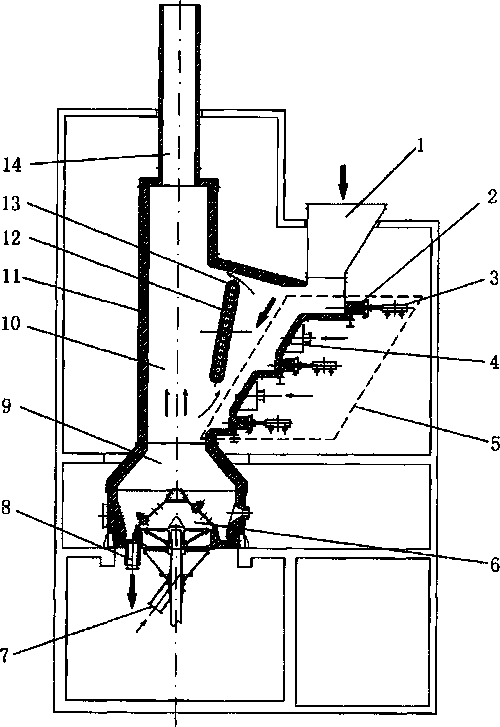

[0011] Such as figure 1 As shown, a double-grate garbage incinerator includes an incinerator body 11, a garbage hopper 1, an incineration grate, and a flue gas outlet 14, wherein the incineration grate is composed of a stepped grate 5 (equipment in a dotted line frame) and a rotating The grate 6 consists of two types of grate, the rotary grate 6 is located at the bottom of the incinerator, the stepped grate 5 is located on the side of the incinerator body above the rotary grate, the garbage feeding hopper 1 is located above the stepped grate, and the rotary grate The inner cavity of the incinerator body 11 above is respectively a primary combustion chamber 9 and a secondary combustion chamber 10 from bottom to top. There is a retaining wall 12 between the stepped grate 5 and the secondary combustion chamber 10, the retaining wall 12 and the stepped There is a gap between the fire grate 5 and the incinerator inner wall above the retaining wall 12 . The inner wall of the incine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com