Energy conservation high-pressure-resistant nonmetal expansion joint

A non-metallic expansion joint technology, which is applied in the field of pipeline compensation devices, can solve problems affecting the compensation function of soft connections, acrobatics, easy dust falling, and affecting the life of the skin, so as to reduce heat loss, achieve significant energy saving effects, and improve rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

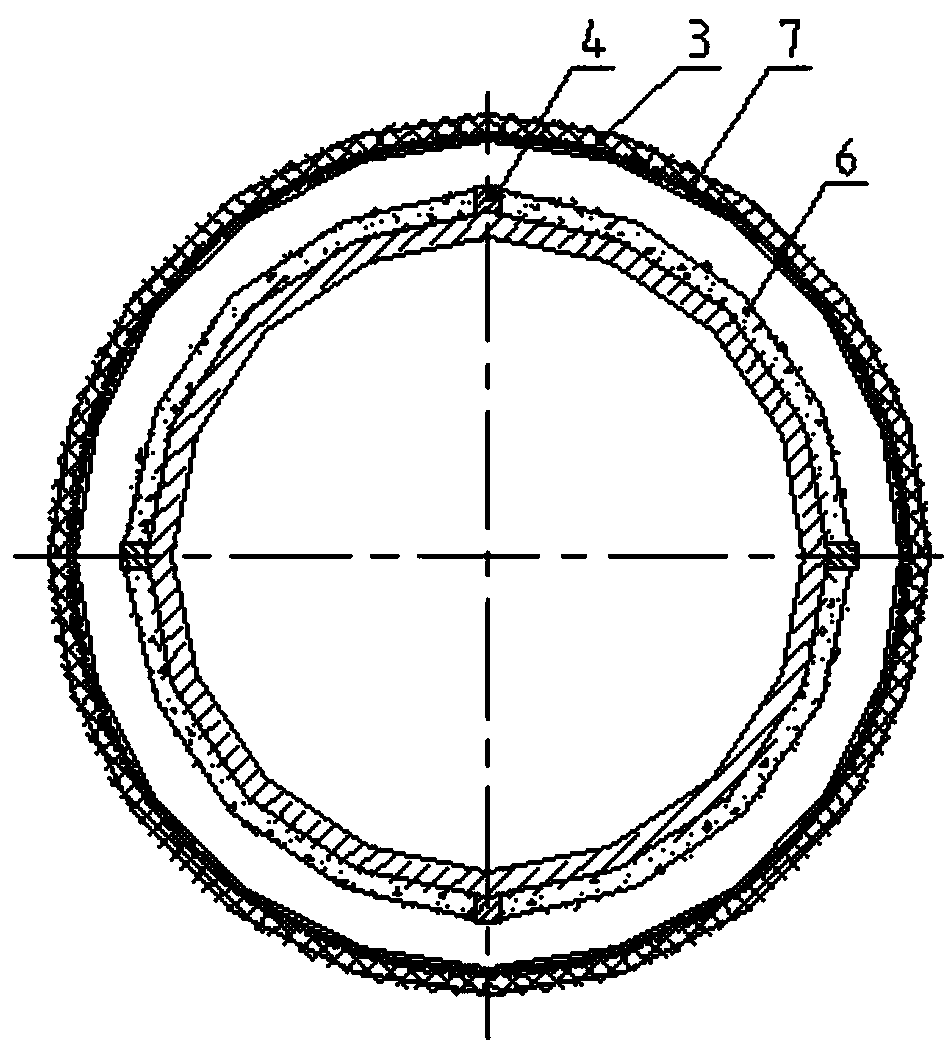

[0018] The energy-saving and high-pressure resistant non-metallic expansion joint shown in the accompanying drawings includes right flange 1, left flange 2, skin 3, and guide tube 5. The inner wall of skin 3 is provided with steel wire mesh 7; both ends of skin 3 are turned outward, They are respectively fixedly connected with the left end surface of right flange 1 and the right end surface of left flange 2 to form a compensation structure; the guide tube 5 includes a straight cylinder and an outward flange at the left end, and the left end of the guide tube 5 is clamped on the left flange. Between the right end face of the flange 2 and the left end flange of the skin 3, a heat-resistant layer 6 is provided on the outer wall of the straight cylinder, the straight cylinder axially penetrates the skin 3, and the right end protrudes from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com