Track type lifting platform hydraulic drilling rig and working method thereof

A lifting platform, hydraulic drilling rig technology, applied in drilling equipment and methods, directional drilling, earth-moving drilling, etc. The effect of reducing the environment and labor intensity, overcoming the large limitation of the punching angle, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

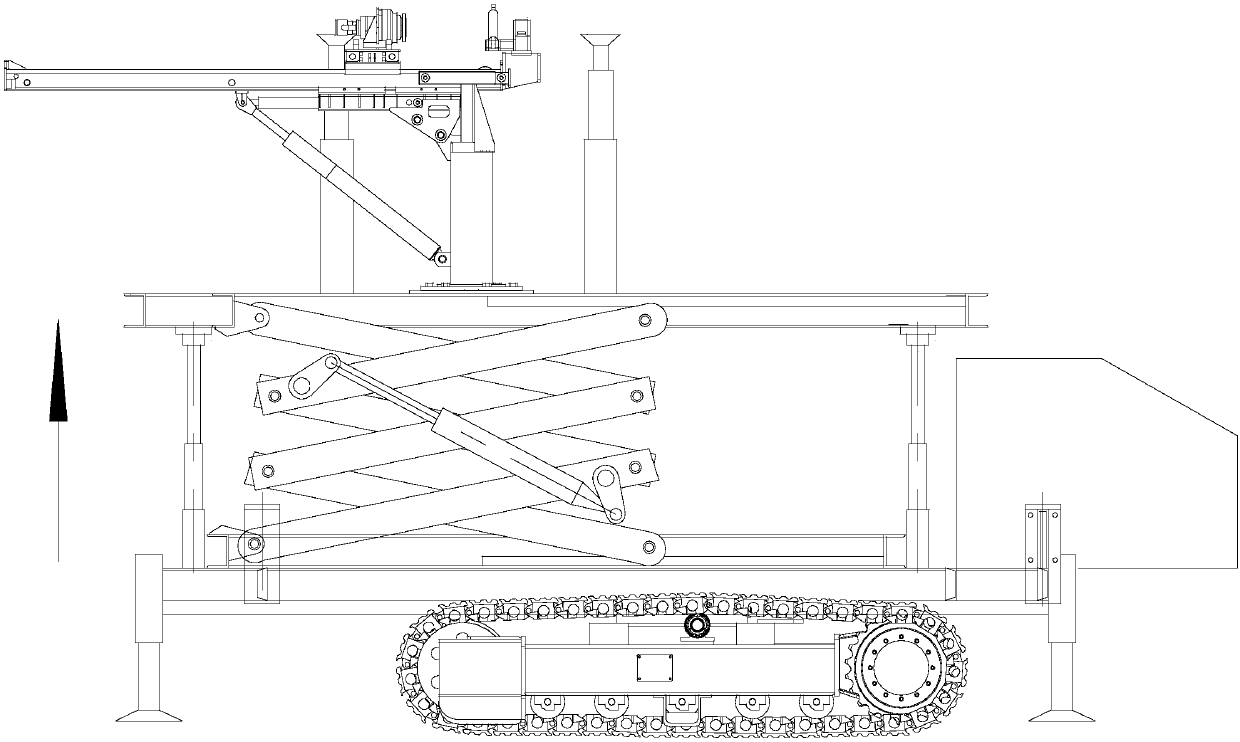

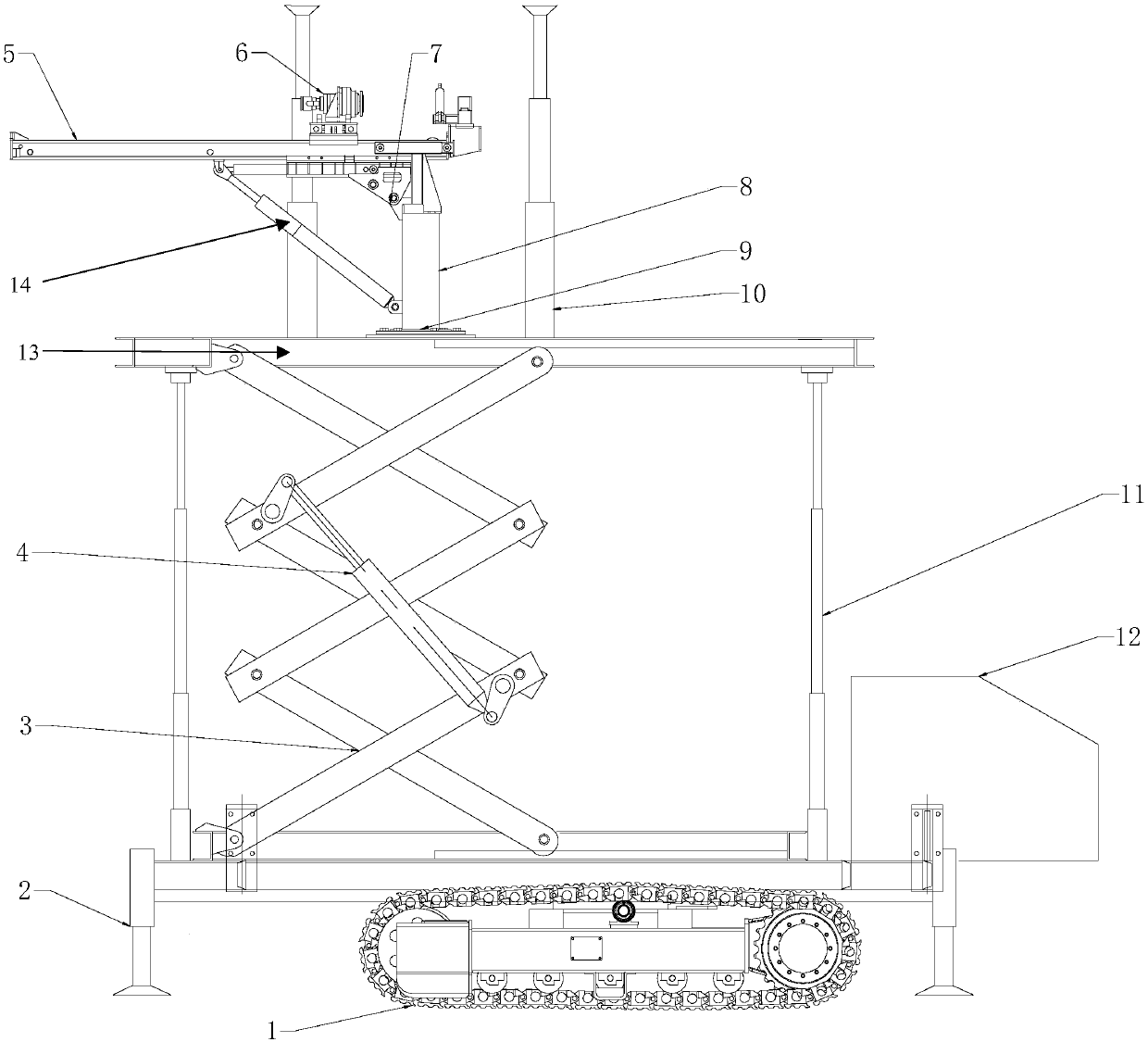

[0035] A crawler-type lifting platform hydraulic drilling rig, including a power system, a hydraulic system, a walking support system, a drilling system and an electrical system; the power system includes a diesel engine, and the diesel engine is an R4105 diesel engine; the power system provides power output for the entire drilling rig; The power drives the hydraulic system and various components to complete various predetermined actions.

[0036] The walking support system includes a base, a crawler is provided under the base, and the diesel engine drives the crawler to walk. There are four supporting columns around the base, and a lifting platform is arranged above the base. cylinder;

[0037] There is a drilling system above the lifting platform. The drilling system includes a carriage slewing assembly on the lifting platform. The carriage slewing assembly is equipped with a carriage column and a carriage jacking cylinder, and the carriage column is hinged to the carriage. ...

Embodiment 2

[0040] A crawler-type lifting platform hydraulic drilling rig, the structure of which is as described in Embodiment 1, the difference is that the two ends of the platform lifting cylinder are connected with the lifting frame through the connecting plate, the connecting plate and the platform lifting cylinder, and the connecting plate and the lifting frame Both are hinged. In order to adapt to the steering during the lifting process.

Embodiment 3

[0042] A crawler-type lifting platform hydraulic drilling rig, its structure is as described in Embodiment 1, the difference is that the number of the first support cylinder is three, the first support cylinder is arranged on the lifting platform above the lifting frame, the first support The oil cylinders are evenly distributed along the circumference of the carriage column. ; The number of the second supporting oil cylinder is four, and the second supporting oil cylinder is evenly arranged around the lifting platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com