Bridge rectifier tool preheating table

A bridge stack and tooling technology, applied in the field of bridge stack tooling preheating platform, can solve the problems of low heat treatment efficiency, slow production efficiency, slow heating, etc., and achieve the effects of improving production efficiency, improving heat treatment efficiency, and shortening buffer time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

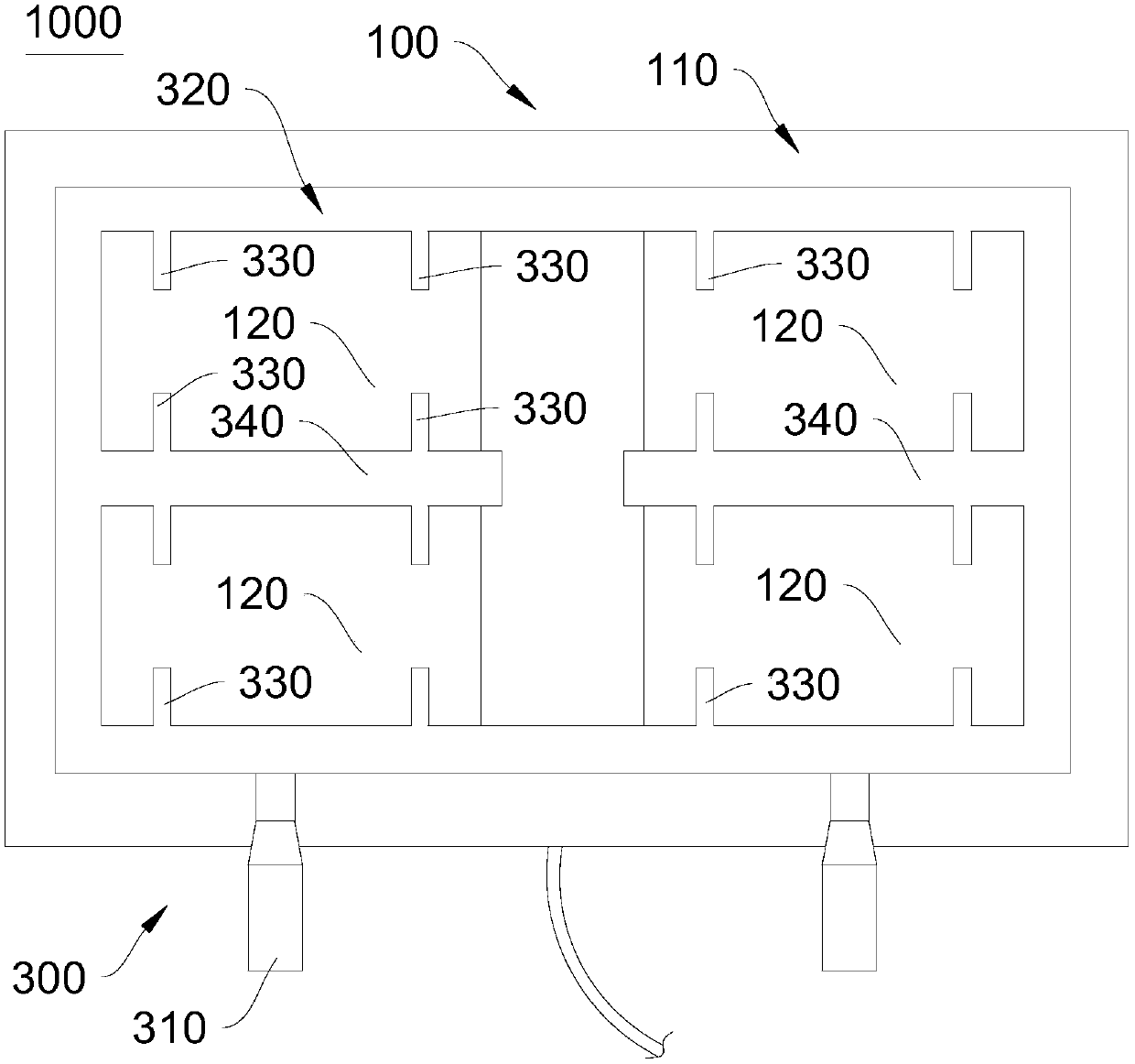

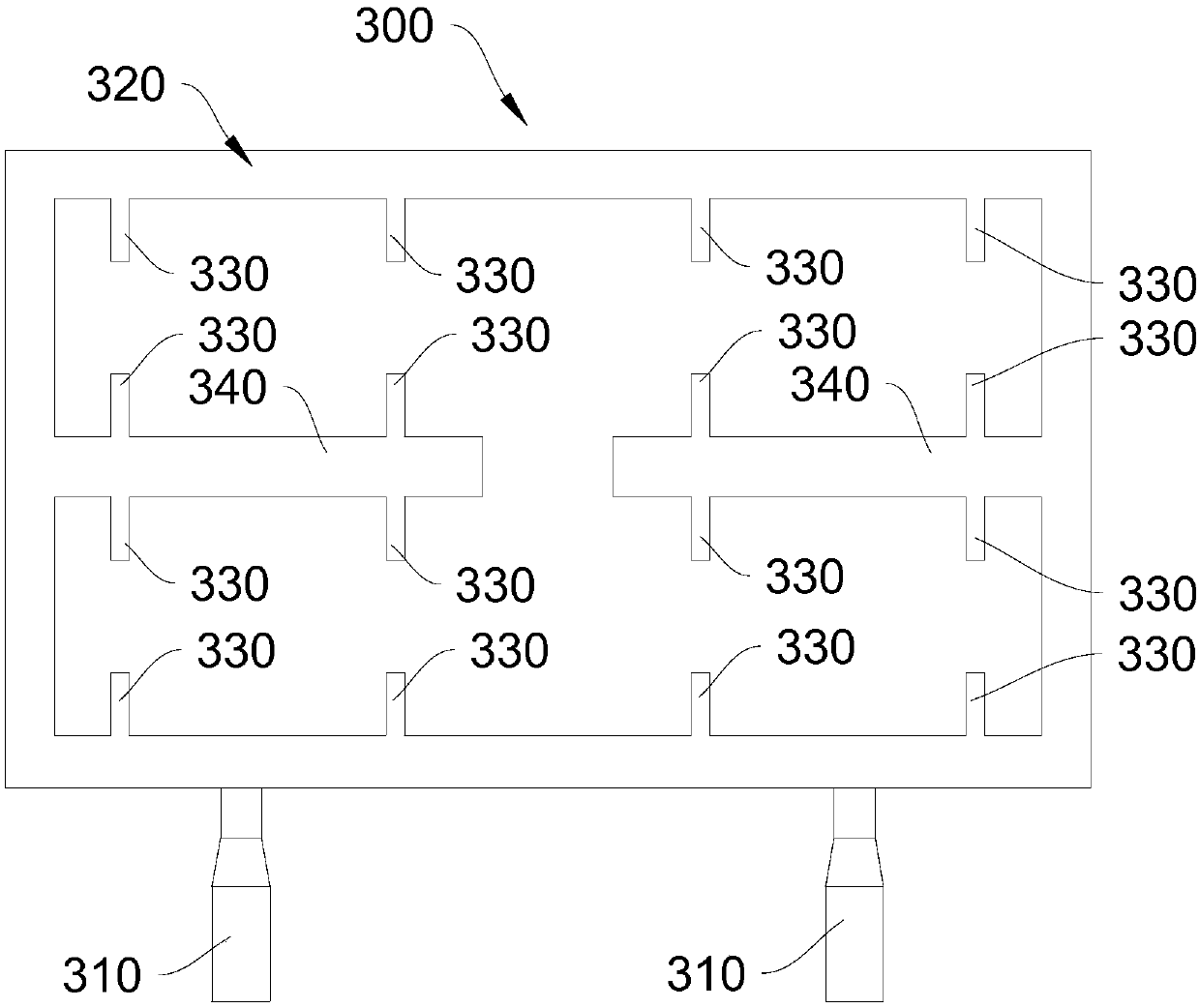

[0034] Please refer to Figure 1~6 , the present embodiment provides a bridge stack tooling preheating platform 1000, and the bridge stack tooling preheating platform 1000 includes: a base 100, a heating wire 200, a hand frame 300 and a power supply assembly.

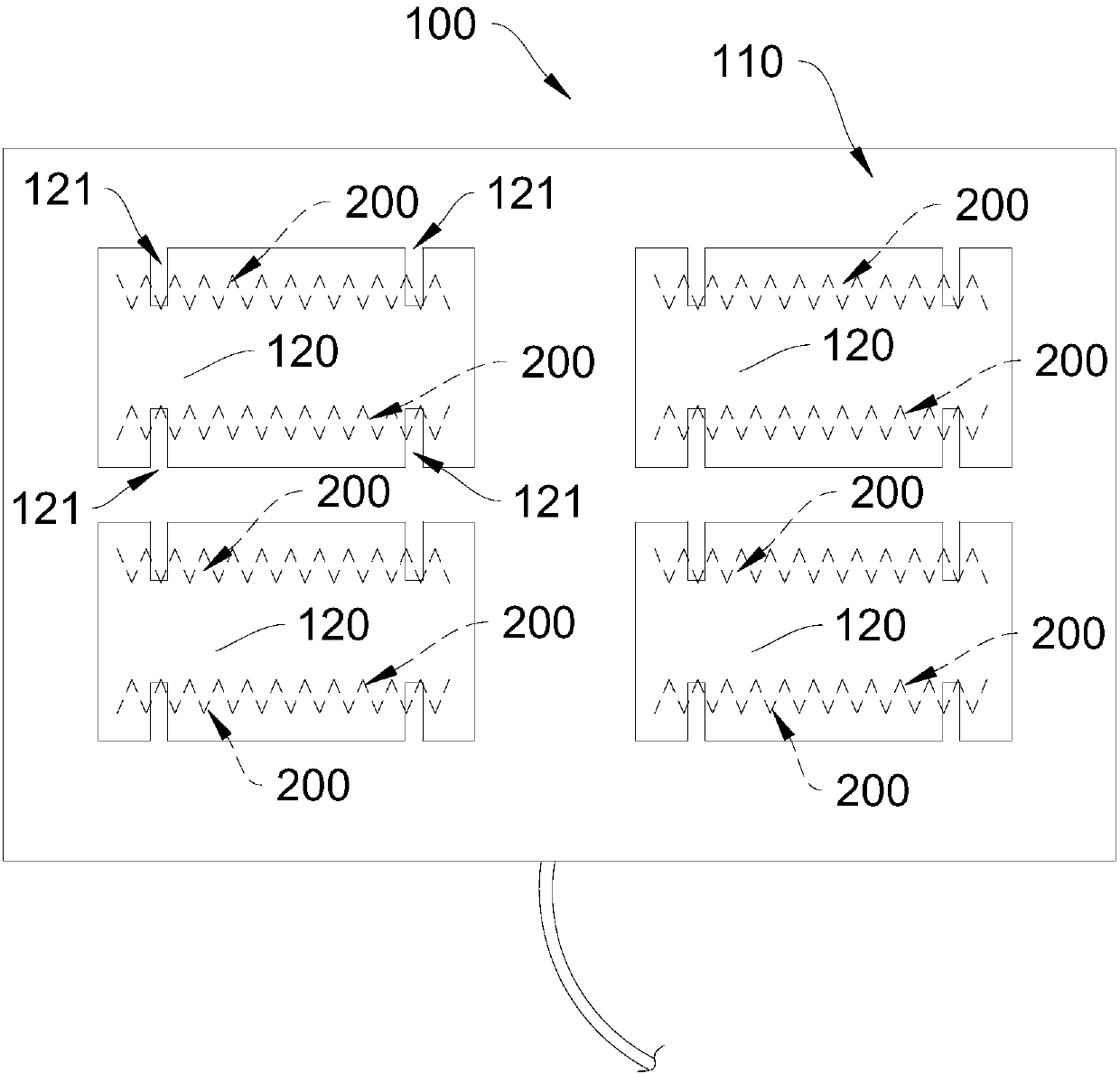

[0035] The base 100 has a preheating part 120 for preheating the bridge stack, and the preheating part 120 is protruded from the table 110 of the base 100 . The edge of the preheating part 120 has a plurality of strip-shaped notches 121 , and the plurality of strip-shaped notches 121 are all extended from the edge to the opposite side. In this embodiment, the strip-shaped notch 121 is recessed from the top of the preheating part 120 toward the table top 110 of the submount 100 and is recessed to the table top 110 .

[0036] The preheating unit 120 has an inner cavity. The top wall of the preheating part 120 is made of heat conducting material. The heating wire 200 is disposed in the inner cavity.

[0037] The hand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com