Method for treating ASP flooding produced water by chlorine dioxide in combination with SSF (suspended sludge filtration) process

A technology of suspended sludge filtration and ternary compounding, which is applied in the direction of oxidized water/sewage treatment, filtration treatment, water/sludge/sewage treatment, etc. Eliminate problems such as rising effluent treatment costs, and achieve the effects of reducing treatment costs, reducing dosage, and reducing sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

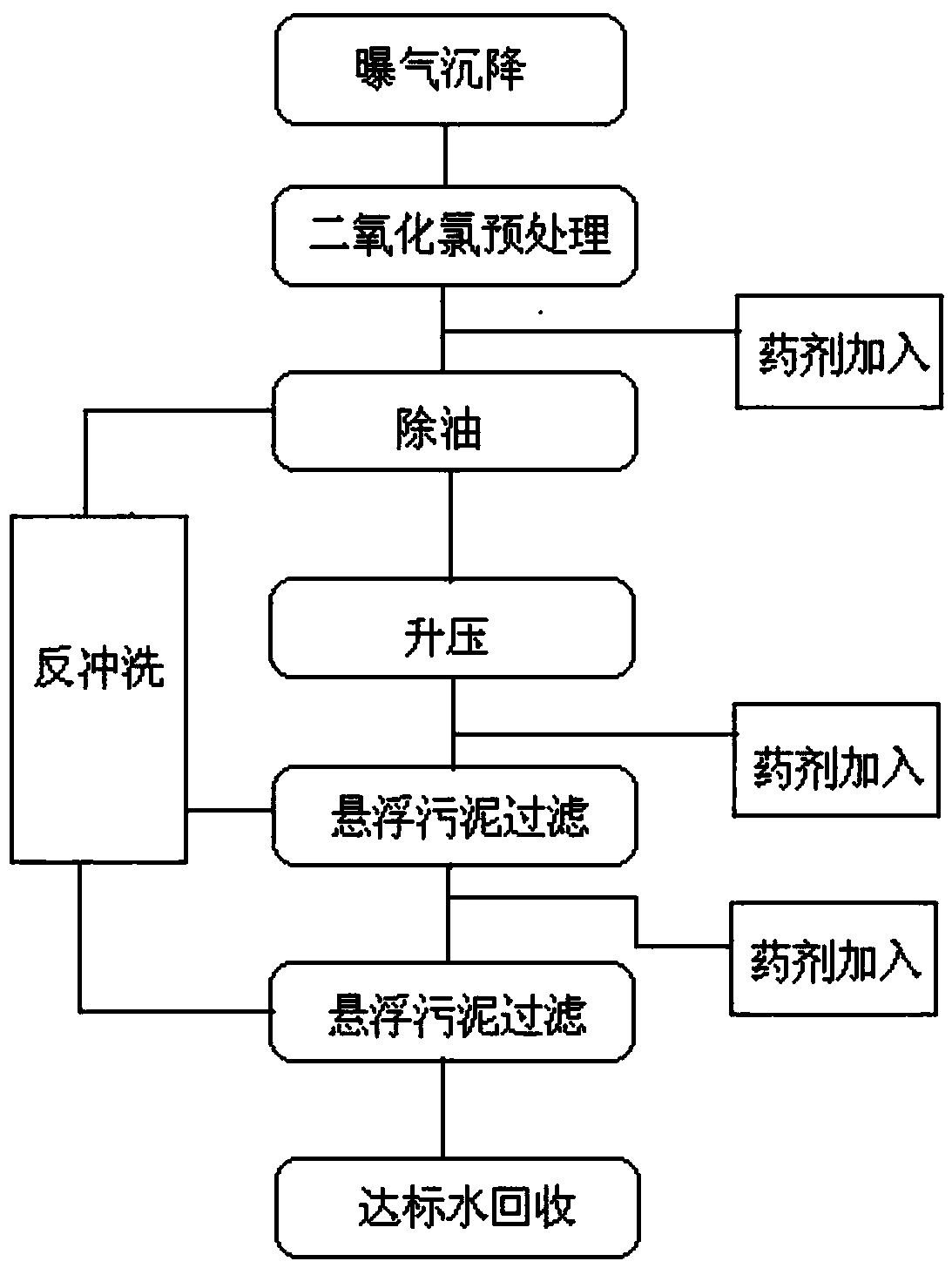

[0043] A method for treating produced water from ASP flooding with chlorine dioxide combined with SSF suspended sludge filtration process, comprising the following steps:

[0044] Step 1. Aeration and settlement: aeration and settlement of the produced water from ASP flooding;

[0045] Step 2, chlorine dioxide pretreatment: pass the produced water of ASP flooding after aeration and settlement into chlorine dioxide for pretreatment;

[0046] Step 3. Degreasing: After adding degreasing agent to the produced water of ASP flooding after chlorine dioxide pretreatment, enter the two-way flow degreaser for degreasing, and add oil to the two-way flow degreaser during the deoiling process Viscosity reducer;

[0047] Step 4. Pressure boosting and buffering: boosting the pressure of the ASP flooding produced water after deoiling;

[0048] Step 5. Filtration of suspended sludge: Add flocculant to the produced water of ASP flooding after boosting pressure, and then enter the suspended sl...

specific Embodiment approach 2

[0066] A method for treating produced water from ASP flooding with chlorine dioxide combined with SSF suspended sludge filtration process, comprising the following steps:

[0067] Step 1. Aeration and settlement: aeration and settlement of the produced water from ASP flooding;

[0068] Step 2, chlorine dioxide pretreatment: pass the produced water of ASP flooding after aeration and settlement into chlorine dioxide for pretreatment;

[0069] Step 3. Degreasing: After adding degreasing agent to the produced water of ASP flooding after chlorine dioxide pretreatment, enter the two-way flow degreaser for degreasing, and add oil to the two-way flow degreaser during the deoiling process Viscosity reducer;

[0070] Step 4. Pressure boosting and buffering: boosting the pressure of the ASP flooding produced water after deoiling;

[0071] Step 5. Filtration of suspended sludge: add flocculant to the produced water of ASP flooding after boosting pressure, and then enter the suspended sl...

specific Embodiment approach 3

[0083] A method for treating produced water from ASP flooding with chlorine dioxide combined with SSF suspended sludge filtration process, comprising the following steps:

[0084] Step 1. Aeration and settlement: aeration and settlement of the produced water from ASP flooding;

[0085] Step 2, chlorine dioxide pretreatment: pass the produced water of ASP flooding after aeration and settlement into chlorine dioxide for pretreatment;

[0086] Step 3. Degreasing: After adding degreasing agent to the produced water of ASP flooding after chlorine dioxide pretreatment, enter the two-way flow degreaser for degreasing, and add oil to the two-way flow degreaser during the deoiling process Viscosity reducer;

[0087] Step 4. Pressure boosting and buffering: boosting the pressure of the ASP flooding produced water after deoiling;

[0088] Step 5. Filtration of suspended sludge: Add flocculant to the produced water of ASP flooding after boosting pressure, and then enter the suspended sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com