Zirconium carbonate special for synthesis of potassium zirconium carbonate water-resistant crosslinker and preparation method thereof

A technology of potassium zirconium carbonate and zirconium carbonate, which is applied in the field of zirconium carbonate and its preparation, can solve the problems of reduced product activity, difficulty in control, and low product content, and achieve the goals of reducing salt content, reducing waste water discharge, and reducing the amount of acid used Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

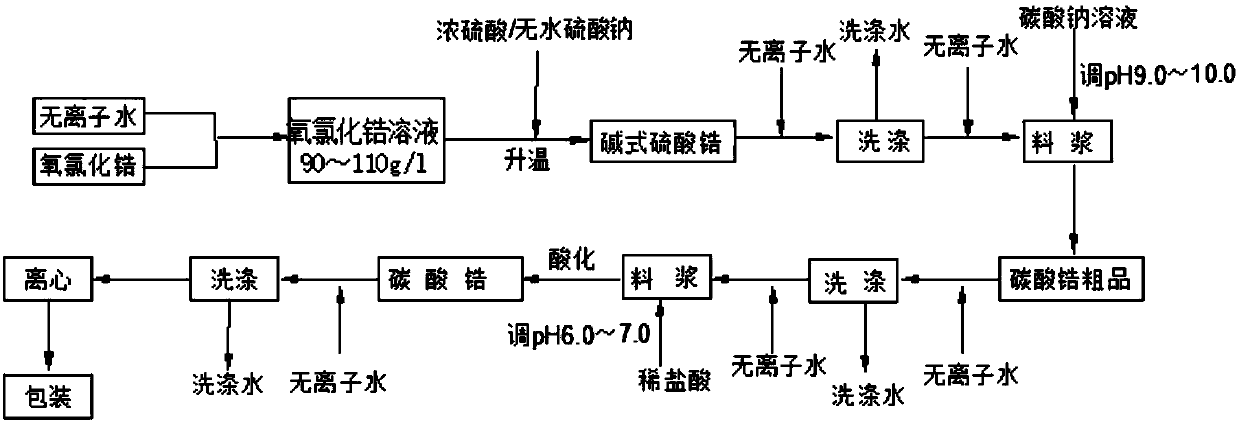

Method used

Image

Examples

Embodiment 1

[0112] A method for preparing zirconium carbonate specially used for synthesizing potassium zirconium carbonate water-resistant crosslinking agent of the present invention. Including the following steps:

[0113] ①. Preparation of basic zirconium sulfate

[0114]a. Preparation of zirconium oxychloride solution

[0115] In the stirring reaction kettle, drop into deionized water and zirconium oxychloride, stir and dissolve, and prepare a zirconium oxychloride aqueous solution of 110g / l;

[0116] b. Preparation of basic zirconium sulfate

[0117] Under stirring, add concentrated sulfuric acid or anhydrous sodium sulfate dropwise to the zirconium oxychloride aqueous solution prepared in item a to control SO 4 2- : ZrO 2 The molar ratio is 0.7, the heating rate is controlled at 1°C / min, the temperature rises to 90°C, and at 90°C, the reaction is kept for 1 to 1.5 hours, and the filter is prepared;

[0118] c. Filtration, washing, pulping

[0119] Step 1. The basic zirconium ...

Embodiment 2

[0140] A method for preparing zirconium carbonate specially used for synthesizing potassium zirconium carbonate water-resistant crosslinking agent of the present invention. Including the following steps:

[0141] ①. Preparation of basic zirconium sulfate

[0142] a. Preparation of zirconium oxychloride solution

[0143] In the stirred reactor, drop into deionized water and zirconium oxychloride, stir and dissolve, and prepare a 90g / l zirconium oxychloride aqueous solution;

[0144] b. Preparation of basic zirconium sulfate

[0145] Under stirring, add concentrated sulfuric acid or anhydrous sodium sulfate dropwise to the zirconium oxychloride aqueous solution prepared in item a to control SO 4 2- : ZrO 2 The molar ratio is 0.6, the heating rate is controlled at 1°C / min, the temperature rises to 90°C, and at 90°C, the reaction is kept for 1 to 1.5 hours, and the filter is prepared;

[0146] c. Filtration, washing, pulping

[0147] Step 1. The basic zirconium sulfate feed...

Embodiment 3

[0168] ①. Preparation of basic zirconium sulfate

[0169] a. Preparation of zirconium oxychloride solution

[0170] In the stirred reactor, drop into deionized water and zirconium oxychloride, stir and dissolve, and prepare a 100g / l zirconium oxychloride aqueous solution;

[0171] b. Preparation of basic zirconium sulfate

[0172] Under stirring, add concentrated sulfuric acid or anhydrous sodium sulfate dropwise to the zirconium oxychloride aqueous solution prepared in item a to control SO 4 2- : ZrO 2 The molar ratio is 0.65, the heating rate is controlled at 1°C / min, the temperature rises to 90°C, and at 90°C, the reaction is kept for 1 to 1.5 hours, and the filter is prepared;

[0173] c. Filtration, washing, pulping

[0174] Step 1. The basic zirconium sulfate feed solution prepared in step 1 is filtered by a belt-type vacuum filter washing machine, and the filter cake is continuously washed with deionized water under vacuum until the pH is qualified, and an appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com