Bolt feeding mechanism of automatic glue spreader for check bolts

A technology of anti-loosening bolts and gluing machine, which is applied to the device, coating, conveyor and other directions of coating liquid on the surface, can solve the problems of high investment cost of enterprises, affecting the efficiency of work, cumbersome mechanical steps, etc., to achieve structural Simple and clear, easy to work, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

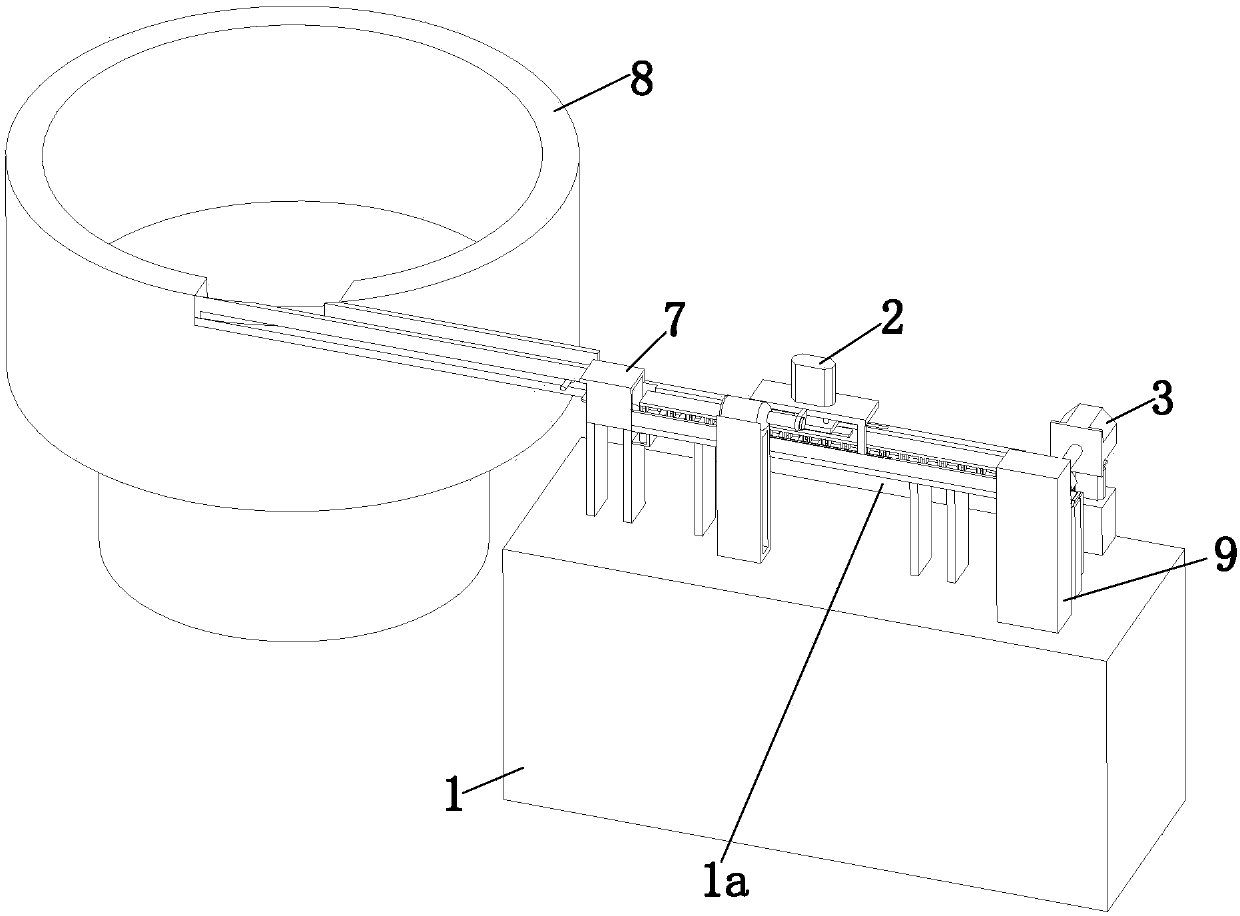

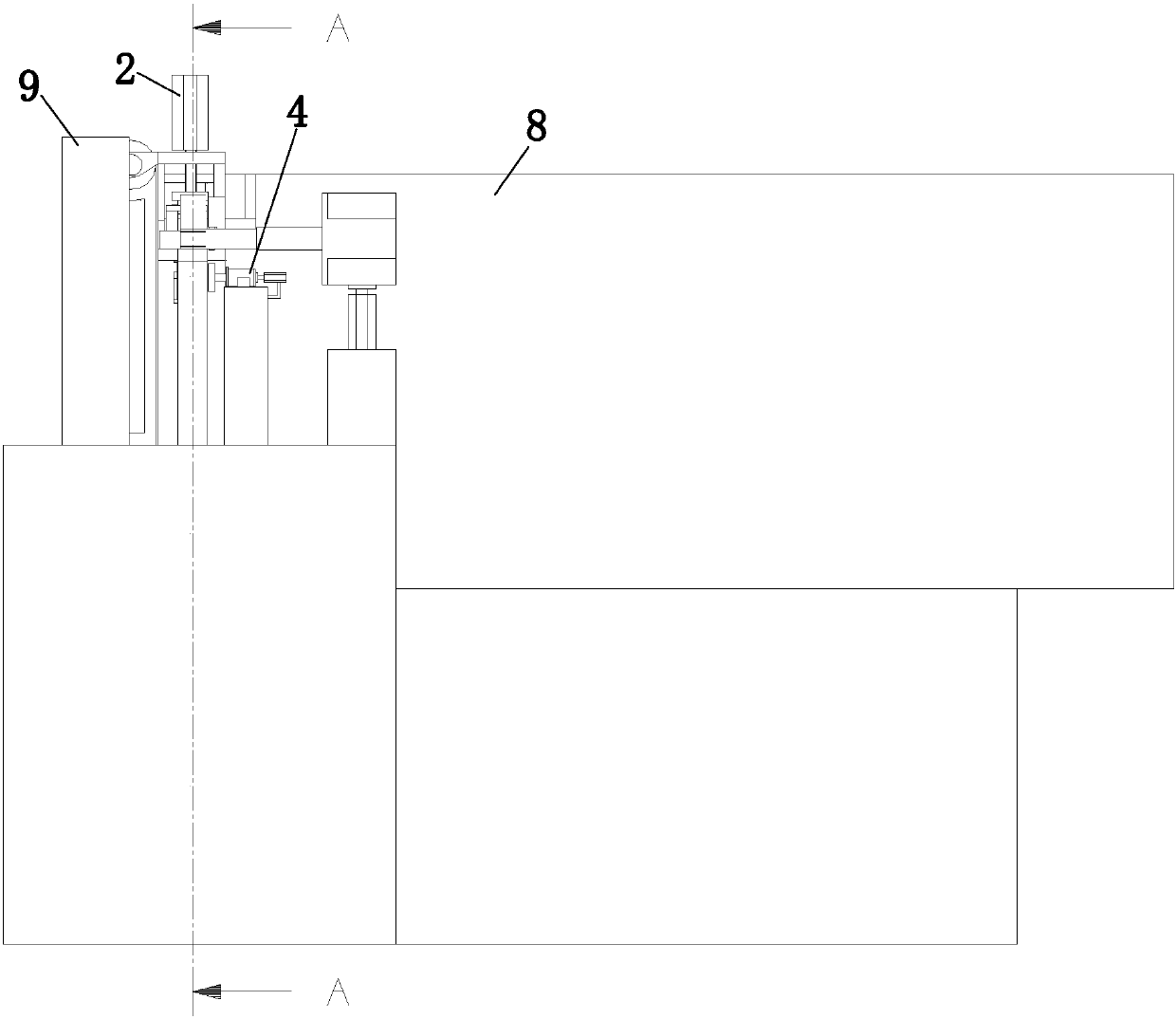

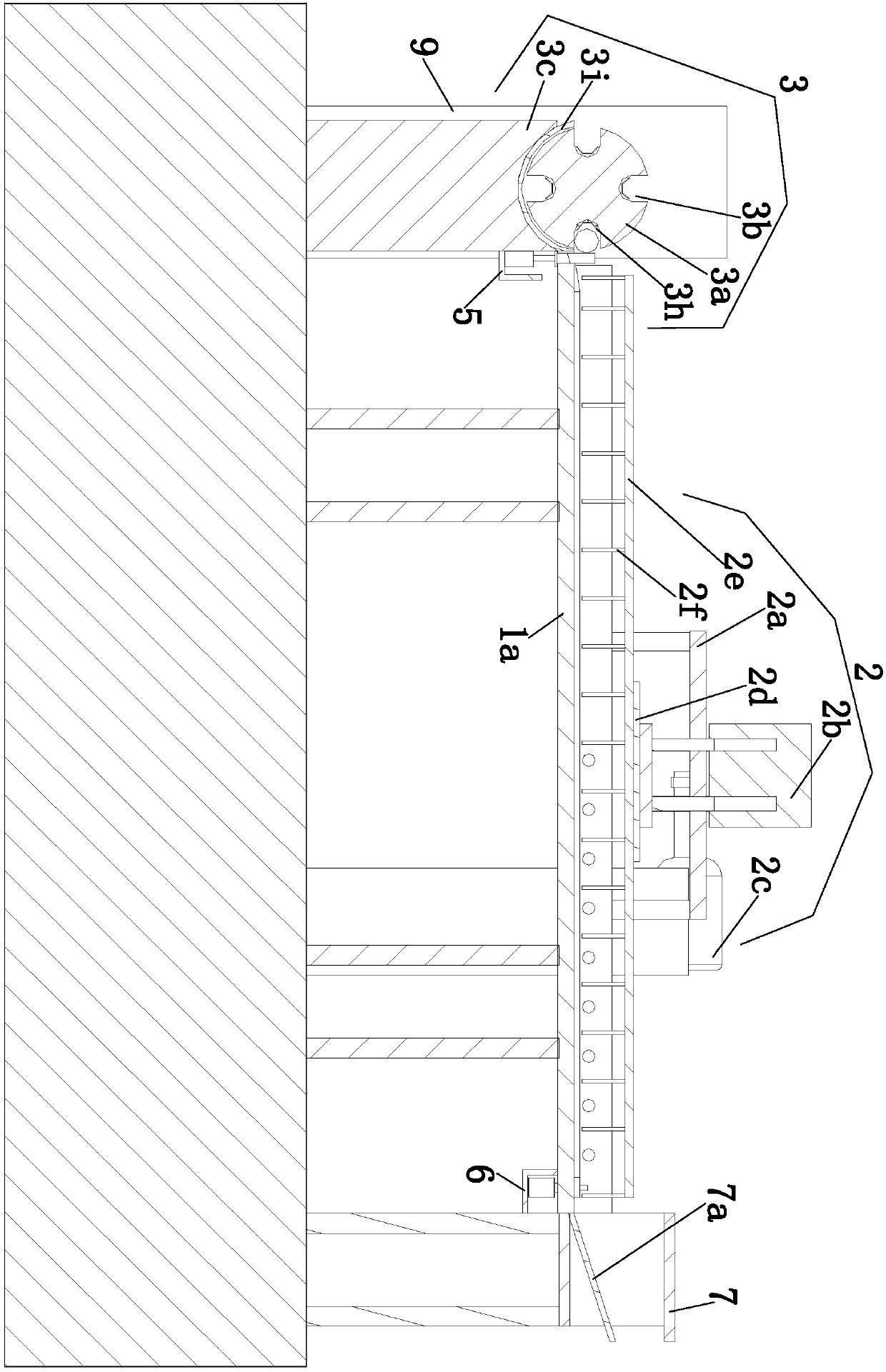

[0026] refer to Figure 1 to Figure 8 The bolt feeding mechanism of an automatic gluing machine for anti-loosening bolts shown includes a base 1, a vibrating plate 8 and a gluing part 9. The base 1 is a rectangular structure, and the top of the base 1 is provided with a The material table 1a, the buffer table 7, the displacement part 2 and the positioning part 3 for locking the material, the displacement part 2 is movably arranged above the feeding table 1a, and the discharge end of the vibrating plate 8 passes through the buffer table 7 and the supply One end of the feeding table 1a is connected, the positioning part 3 is arranged at the other end of the feeding table 1a, the glue-applying part 9 is located at the side of the positioning part 3, and the end of the feeding table 1a facing the positioning part 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com