Crude oil safety heating tank special for crude oil transportation

A technology for heating tanks and crude oil, which is applied in the direction of transporting passenger cars, transportation and packaging, tank cars, etc., can solve problems such as safety accidents, achieve uniform heating and avoid excessive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

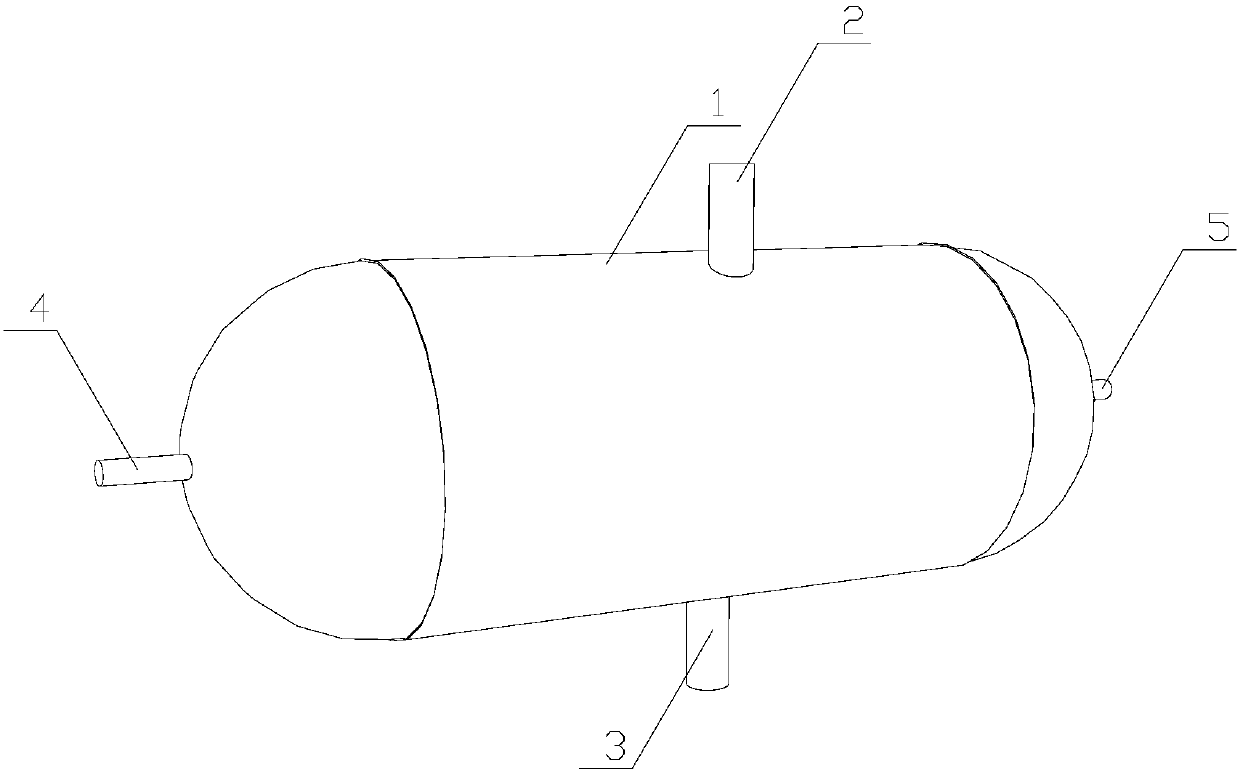

[0030] figure 1 combine figure 2 As shown, the liquid level control device in the tank includes a floating plate 6 floating on the oil surface and at least three guide columns 7 fixed inside the oil tank body 1, and guide columns corresponding to the guide columns 7 are provided on the floating plate 6. hole, the guide post 7 is sleeved in the guide hole, and the upper and lower sides of the floating plate 6 are provided with plugging structures corresponding to the oil inlet pipe 2 and the oil outlet pipe 3 respectively. The columnar oil quantity plug 9 on the elastic plugging column 8 is formed.

[0031] When the floating plate 6 moves upward with the oil level, when the liquid level reaches a certain position, the elastic plugging column 8 on the upper side of the floating plate 6 enters the oil inlet pipe 2 to reduce the amount of oil entering, until the liquid level reaches the highest position, the elastic The plugging column 8 seals the bottom of the oil inlet pipe 2...

Embodiment 2

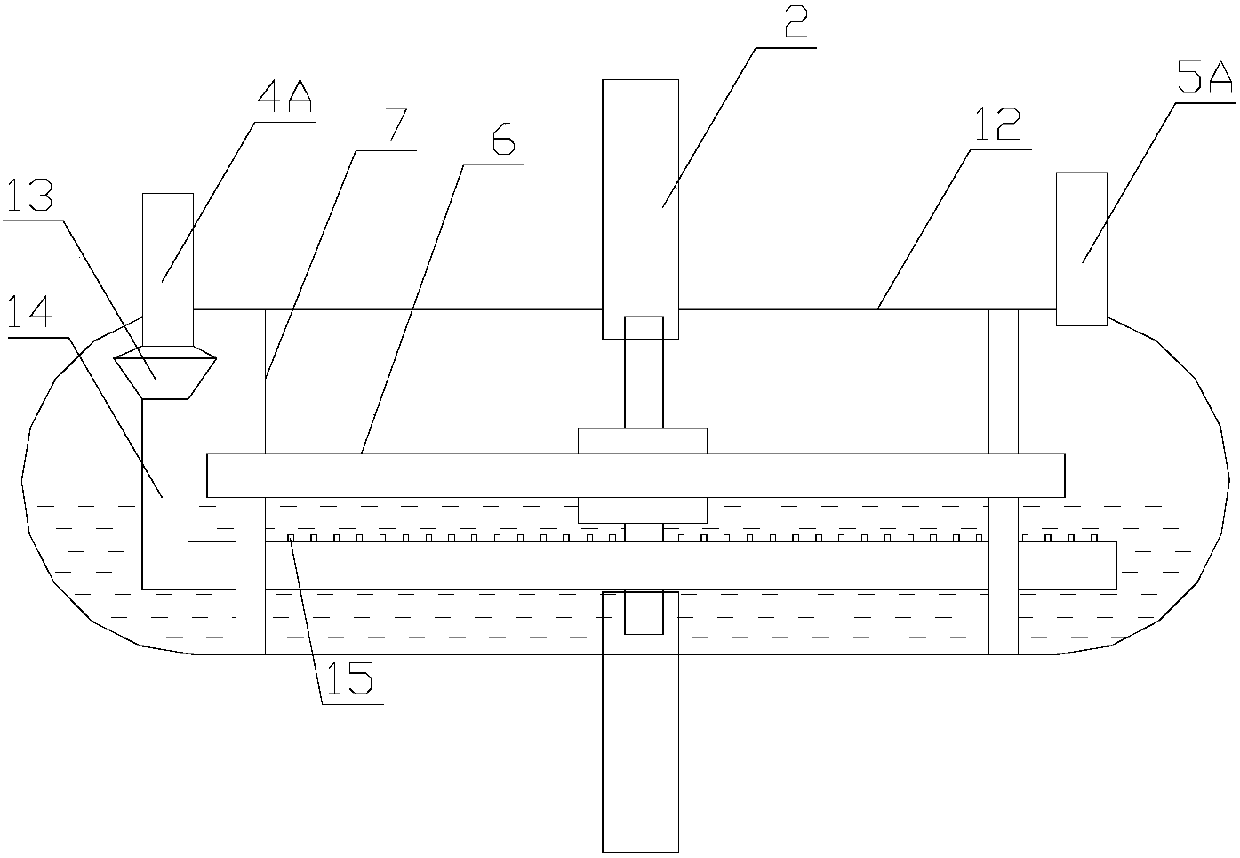

[0038] like image 3 As shown, the liquid level control device in the tank is the same as that in Example 1, and the oil is heated by inert gas with temperature.

[0039] The oil tank body 1 is provided with an air inlet pipe 4A and an air outlet pipe 5A extending to the inside of the oil tank body 1, and the ends of the air inlet pipe 4A and the air outlet pipe 5A located in the oil tank body 1 are higher than the oil liquid level, The air intake pipe 4A is located at the bottom of the end in the oil tank body 1 and is connected with an air diffuser 14. The end of the air diffuser 14 is sealed away from the end of the air intake pipe 4A, and the part of the air diffuser 14 located in the oil liquid is evenly distributed with diffusers. Air tubules15.

[0040] In this embodiment, in order to utilize the device smoothly, before the oil enters, the inert gas with high pressure and temperature is passed through the air intake pipe 4A, and the air flow erupted at the air diffuser...

Embodiment 3

[0046] like Figure 4 As shown, the oil heating method is the same as that of Example 1, but the liquid level control device in the tank is different. The columnar oil volume plug 9 is set as a conical oil volume plug 9A, so that the flow of oil into or out of the tank gradually increases. Variety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com