Method for dispersing spherical and spheroidal metal powder without crushing

A metal powder, spherical-like technology, applied in chemical instruments and methods, metal processing equipment, solid separation, etc., to achieve the effect of easy crushing and dispersion, good dispersion, and not easy to be oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1.1 Take 20 kg of spherical SMT001 silver powder, put it into the disperser, add 30 liters of acetone solution dissolved in 500 grams of oleic acid, stir quickly, the speed is 200rpm, and the power is 1.5KW;

[0038] 1.2 After dispersing and coating in the disperser for 40 minutes, take out the material, put it in a hot air oven, and dry it at 95°C for 12 hours;

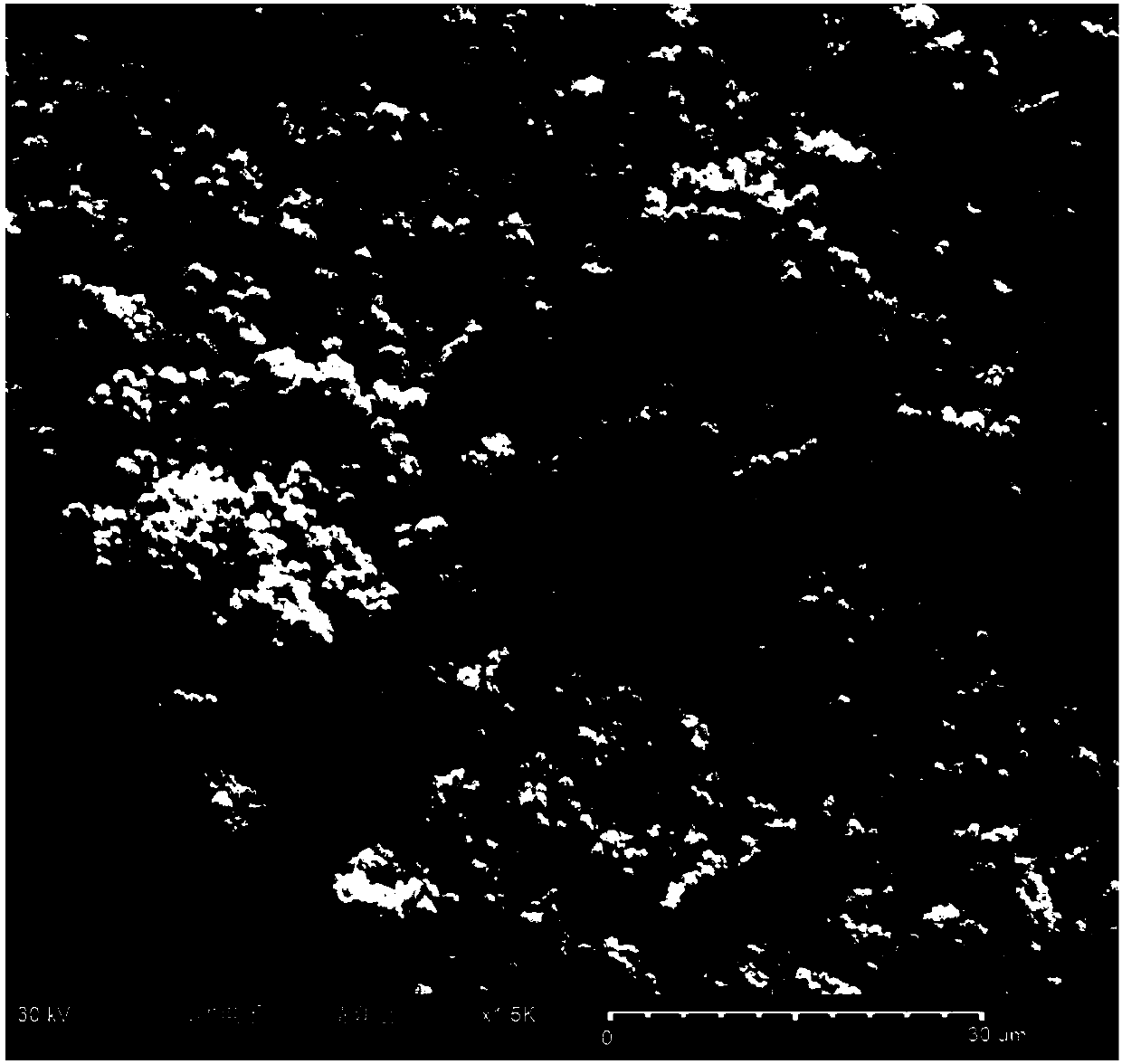

[0039] 1.3 Take out the dried material and put it into a swinging machine (stainless steel filter mesh with a diameter of 10 mm) for pre-crushing (the electron microscope photo of the raw material after pre-crushing is as follows: figure 1 );

[0040] 1.4 Then, the pre-crushed materials are crushed at a speed of 20 kg per minute by a disc-type airflow mill, and the high-pressure airflow uses compressed air: the crushing pressure is 12 kg, and the feeding pressure is 8 kg; the high-pressure airflow inlet in the tangential direction is 6;

[0041] 1.5 Then collect the crushed material through the collection ba...

Embodiment 2

[0046] 2.1 Take 100 kg of S6 series quasi-spherical silver powder, put it into the disperser, add 40 liters of ethanol and ethylene glycol mixed solvent with 500 grams of saturated fatty acid dissolved in a ratio of 1:1, and stir quickly at a speed of 500 rpm;

[0047] 2.2 After dispersing and coating in the disperser for 90 minutes, take out the material, put it in a vacuum oven, dry it at 85 degrees Celsius for 1 hour, take out the material, put it in a swing machine (the aperture of the stainless steel filter is 5 mm) for pre-crushing, After crushing, put it into the oven to continue drying for 15 hours.

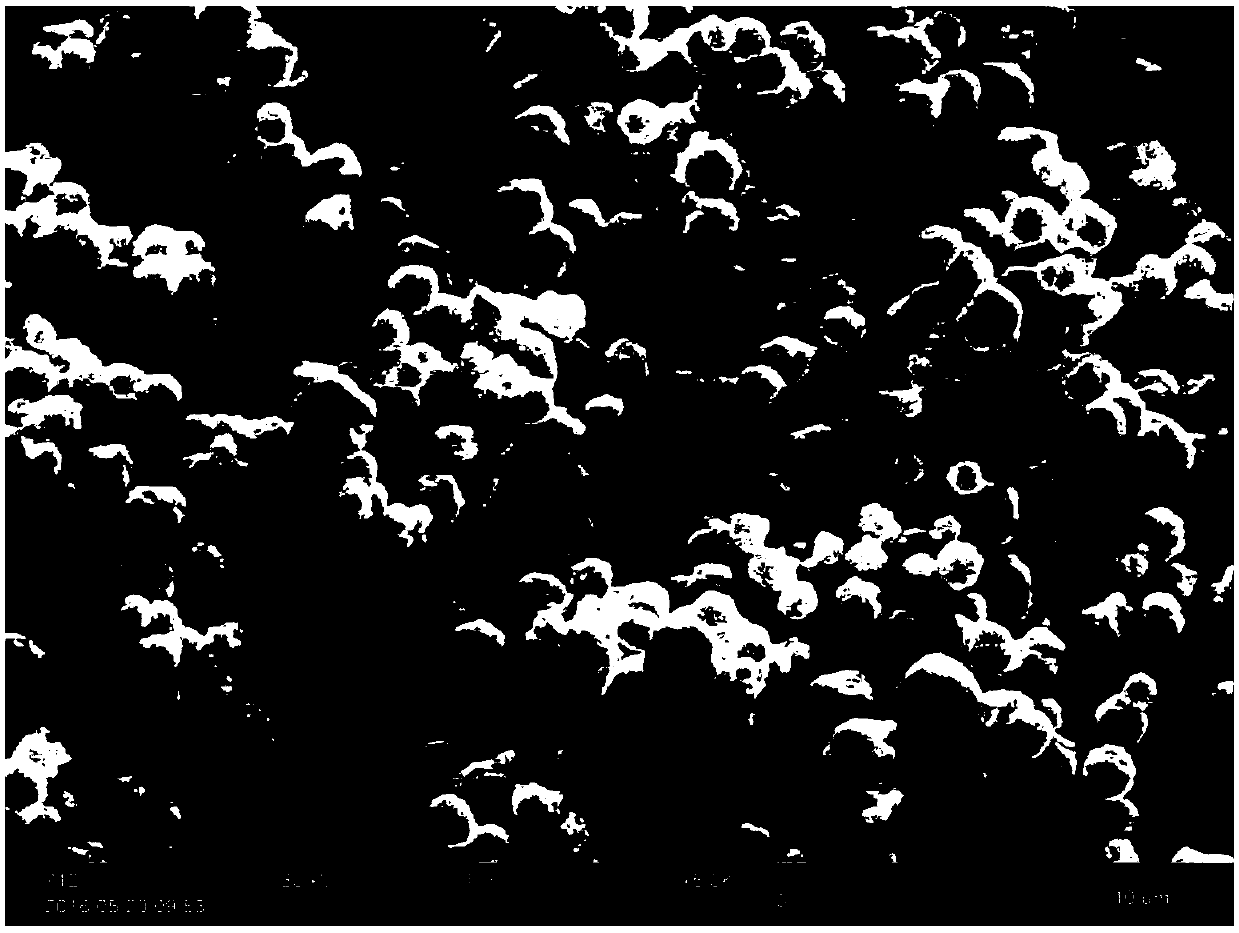

[0048] 2.3 Take out the dried material (at this time, it is the raw material to be crushed, the electron microscope photo is as follows Figure 4 ), using a disc-type airflow mill to crush at a speed of 50 kilograms per minute, and the high-pressure airflow adopts compressed air: the crushing pressure is 11 kilograms, and the feeding pressure is 6 kilograms; there are 8 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com