IPS liquid crystal display screen liquid crystal box preparation method

A liquid crystal box and liquid crystal screen technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems that affect product performance, the film layer cannot achieve electromagnetic shielding, and influence, and achieve high feasibility, uniform force, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

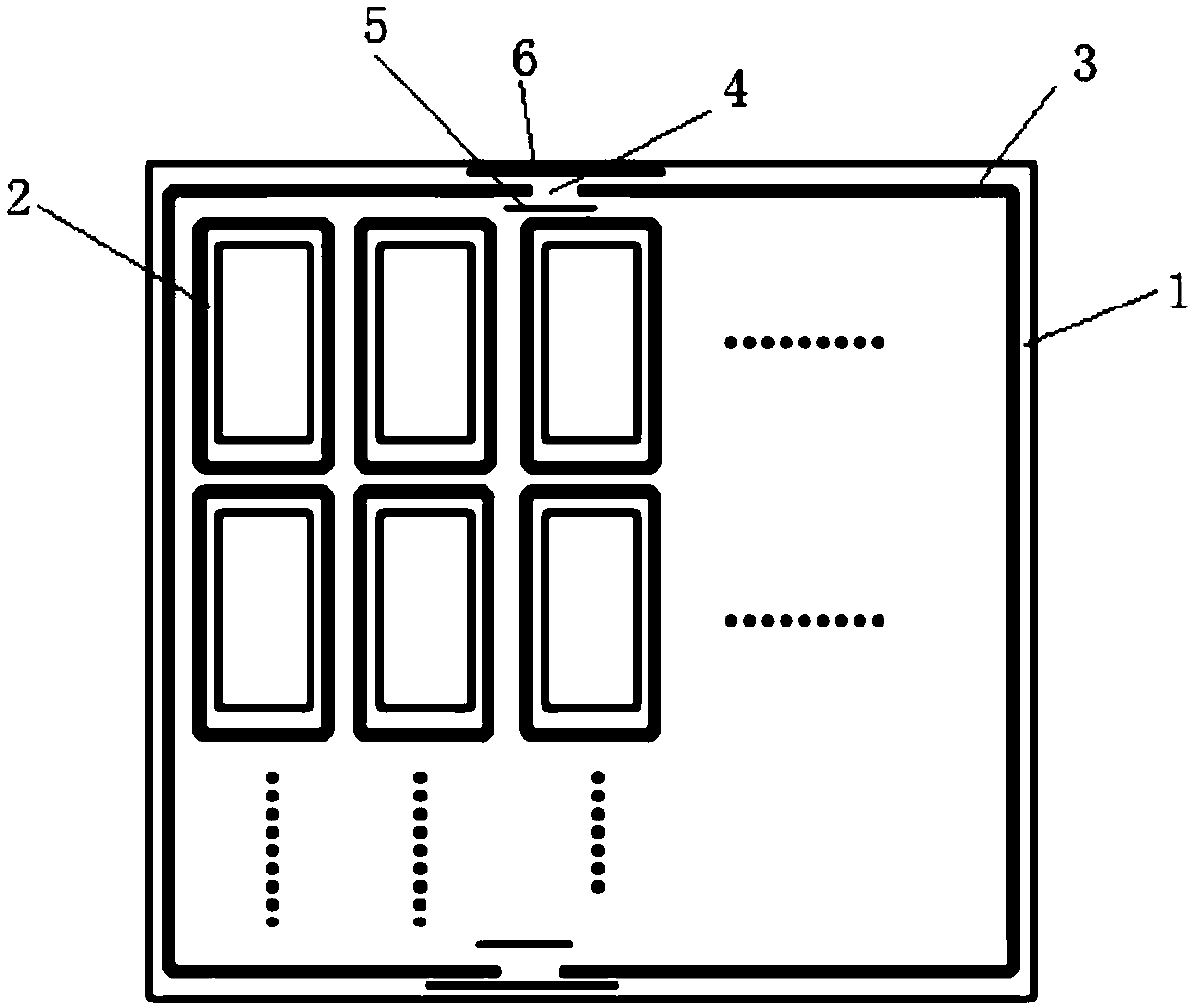

[0015] Embodiment 1: such as figure 1 As shown, a method for preparing a liquid crystal cell of an IPS liquid crystal screen, the steps are: setting a plurality of preset liquid crystal coverage areas at intervals on a CF substrate, and the periphery of the single preset liquid crystal coverage area is surrounded by a frame glue to form a small frame 2 , the preset liquid crystal coverage area can be any number according to the size and model of the IPS liquid crystal screen, and is distributed on the CF substrate in an array. B. On the border of the CF substrate, use the frame glue to form a large frame 3, and surround all the small frames in step A. C. Drop liquid crystal on the TFT substrate through the liquid crystal dropping process; D. Drop the liquid crystal in step C. The surface of the TFT substrate is bonded to the surface of the CF substrate with a frame in step B to form a Cell liquid crystal cell. The large frame is provided with an opening 4, and the opening 4 i...

Embodiment 2

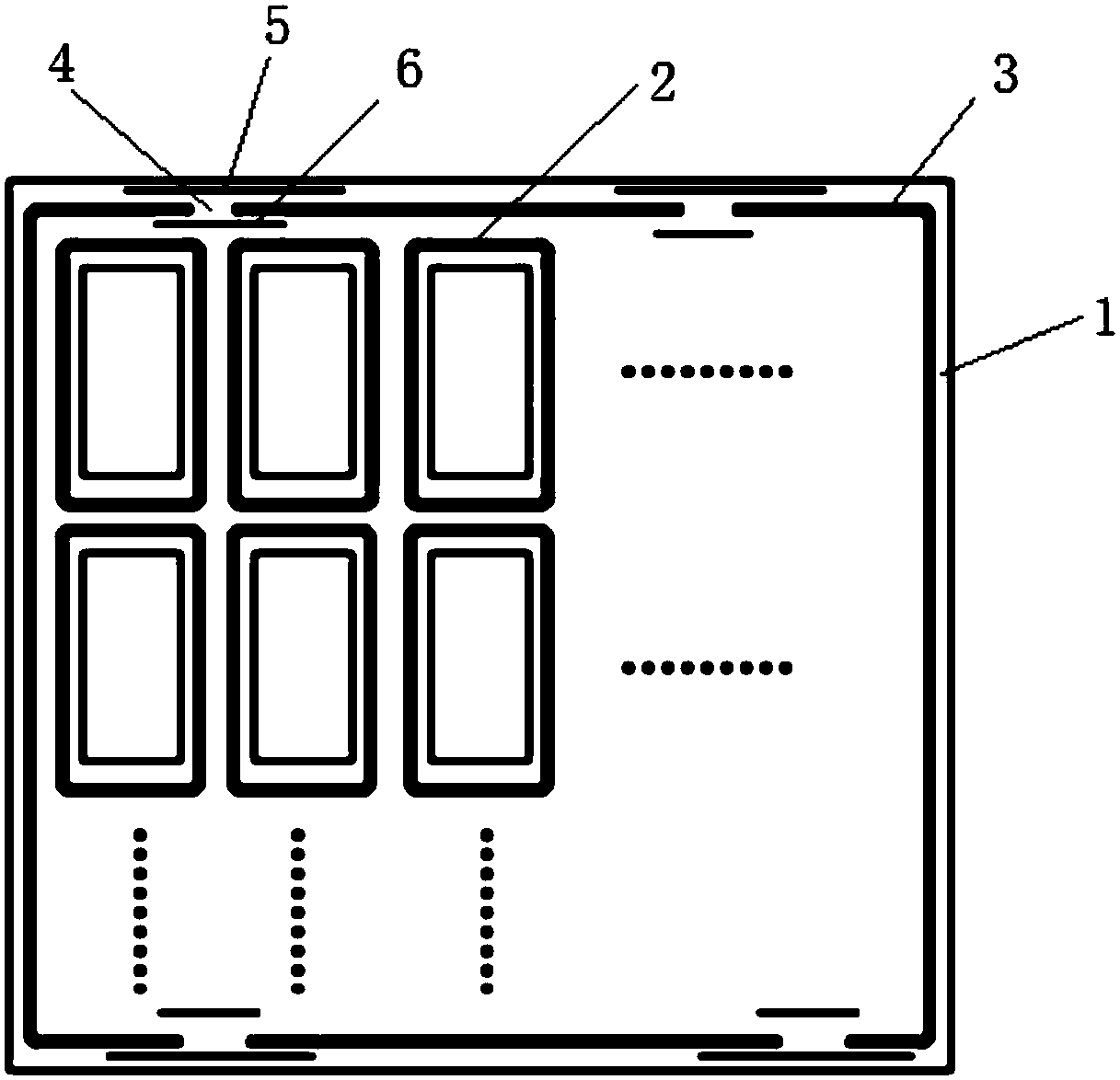

[0016] Embodiment 2: as figure 2 As shown, the difference from Embodiment 1 is that the number of openings 4 provided on the large frame 3 is four, and they are arranged symmetrically in pairs on both sides of the large frame, and the distance between the openings is 15 mm. Both sides of the opening are provided with inner and outer bars in parallel, the opening 4 is in the middle of the two bars, the length of the inner bar 5 is 60mm, and the length of the outer bar 6 is 120mm. The distance between the outer rail 6 and the inner rail 5 is 3mm. The height and width of the outer rail and the inner rail are the same as the height and width of the large frame 3 .

Embodiment 3

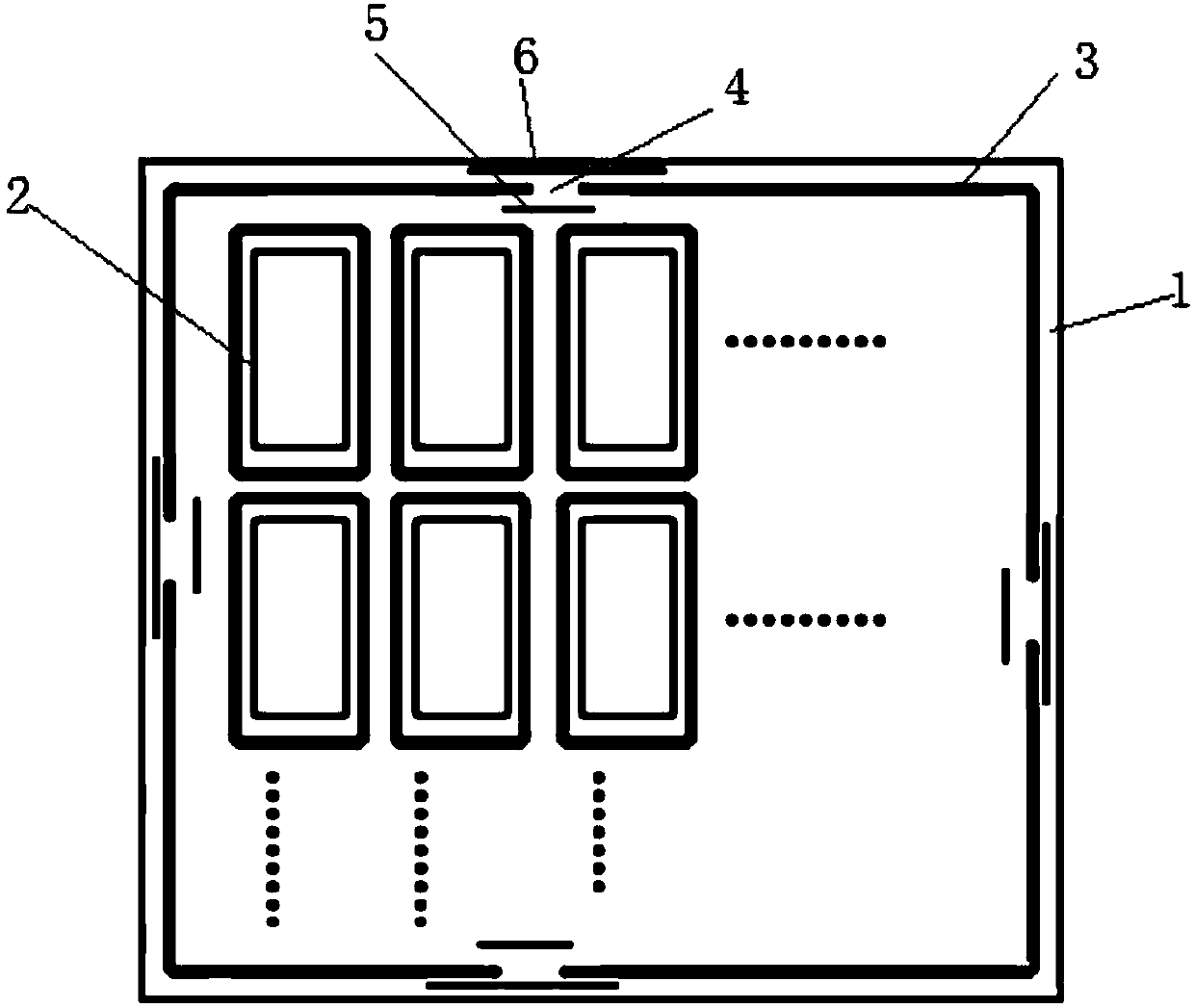

[0017] Embodiment 3: as image 3 As shown, the difference from Embodiment 2 is that the number of openings 4 provided on the large frame 3 is four, and they are symmetrically distributed on the four sides of the large frame.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com