Androgynous cone rod type precise splicing mechanism for space splicing reflection mirror

A technology of heterogeneous isomorphism and mirror, which is applied in the field of space and aerospace, can solve the problems of complex structure and poor splicing accuracy, and achieve the effect of large capture range, reliable positioning and large locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

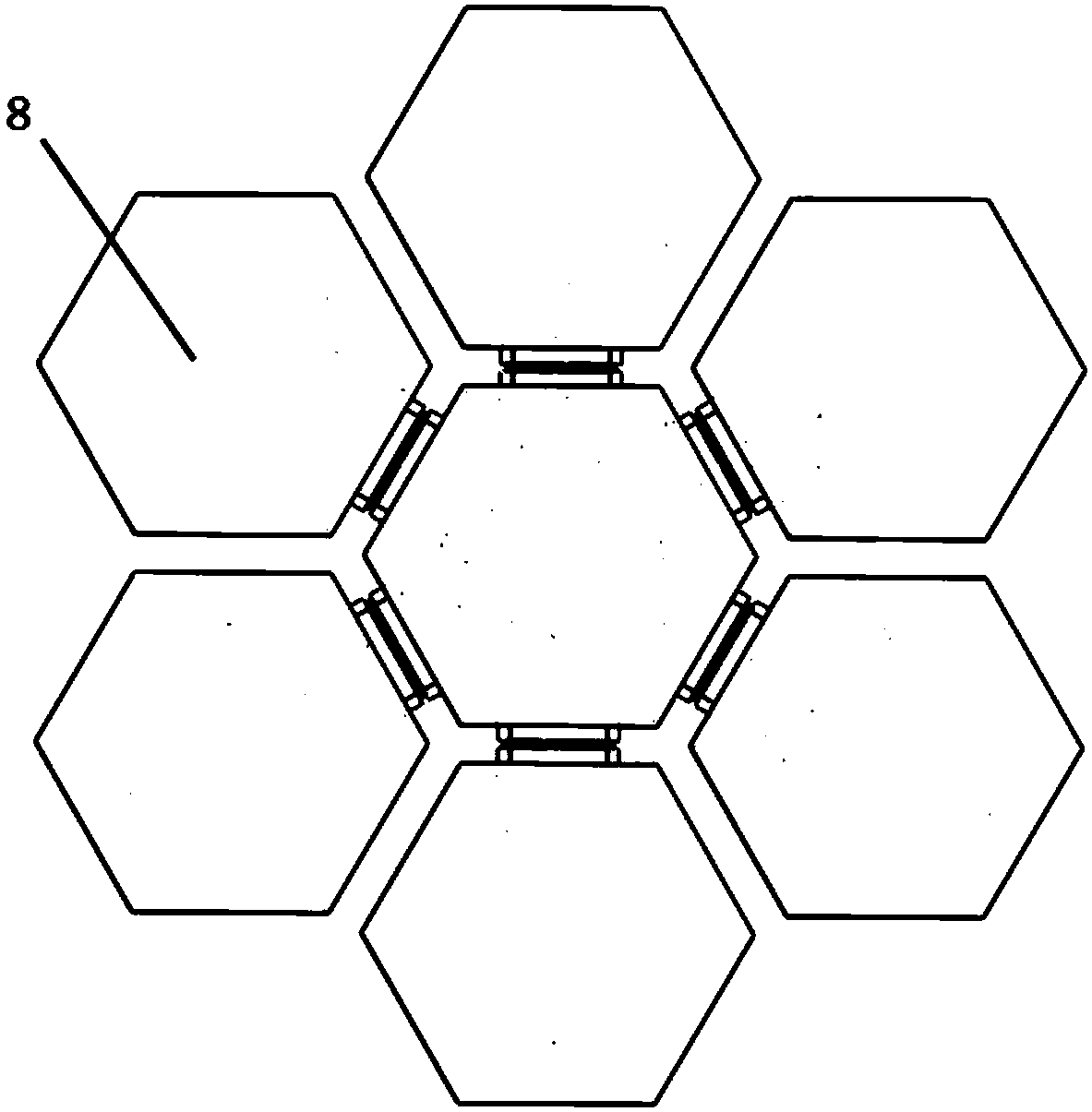

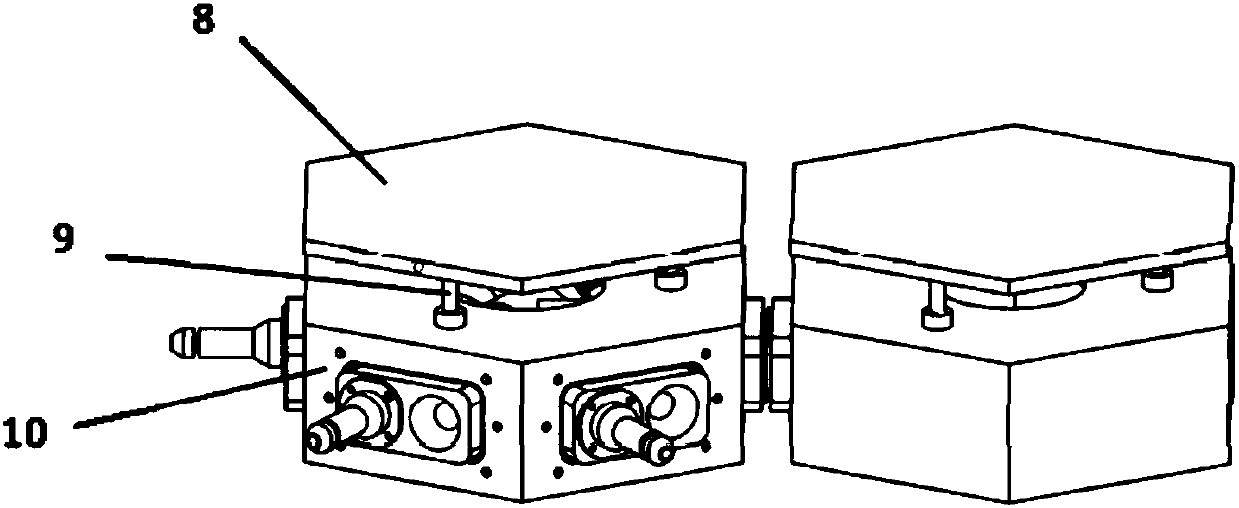

[0043] The present invention is a heterogeneous and isomorphic tapered rod type precision splicing mechanism for spatial splicing mirrors, such as figure 1 with figure 2 As shown, the hexagonal unit mirror module 8 utilizes the heterogeneous and isomorphic taper-rod precision splicing mechanism installed on the mirror base 10 to splice each other to form a complete mirror surface.

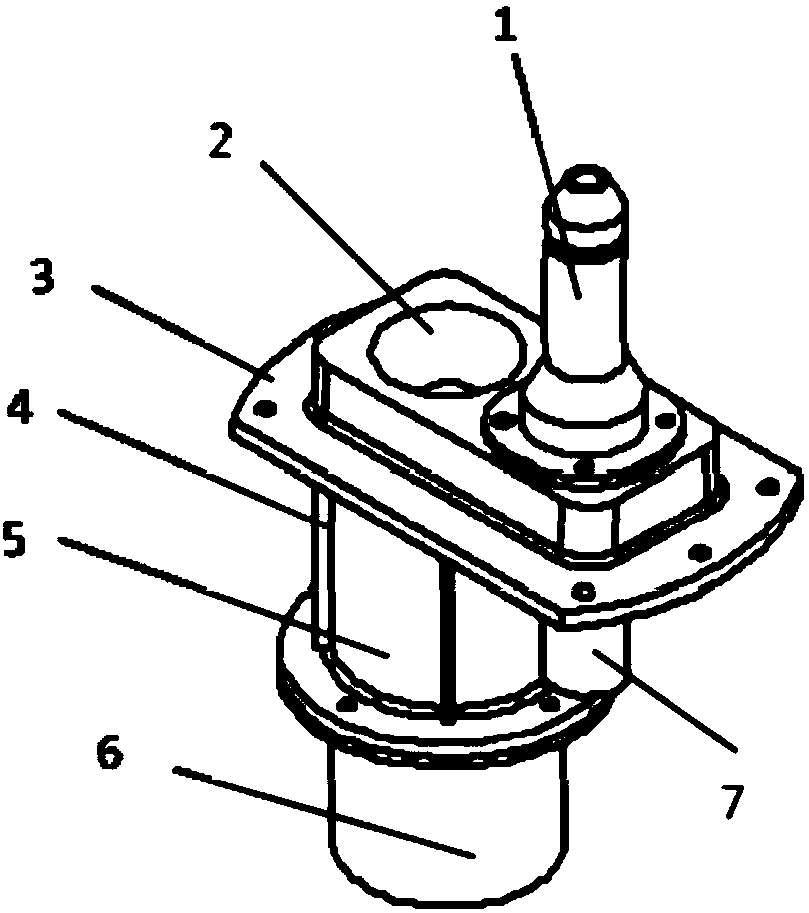

[0044] Such as image 3 with Figure 4 As shown, the structure of the preferred embodiment of the tapered-rod precision splicing mechanism of the present invention includes a supporting main frame, and the supporting main frame can be integrally formed with metal materials.

[0045] The supporting main frame is provided with an installation intermediate plate 3, a capturing device, a positioning device, a locking device, an adjusting device and a separating device; the center of the installation intermediate plate 3 coincides with the center of gravity of the heterogeneous and isomorphic cone-rod precisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com