Method and device for testing shear fatigue resistance of pavement interface under vehicle braking conditions

A technology for vehicle braking and fatigue testing, which is applied in measuring devices, using repetitive force/pulse force to test the strength of materials, instruments, etc. Applicable to a wide range of engineering conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

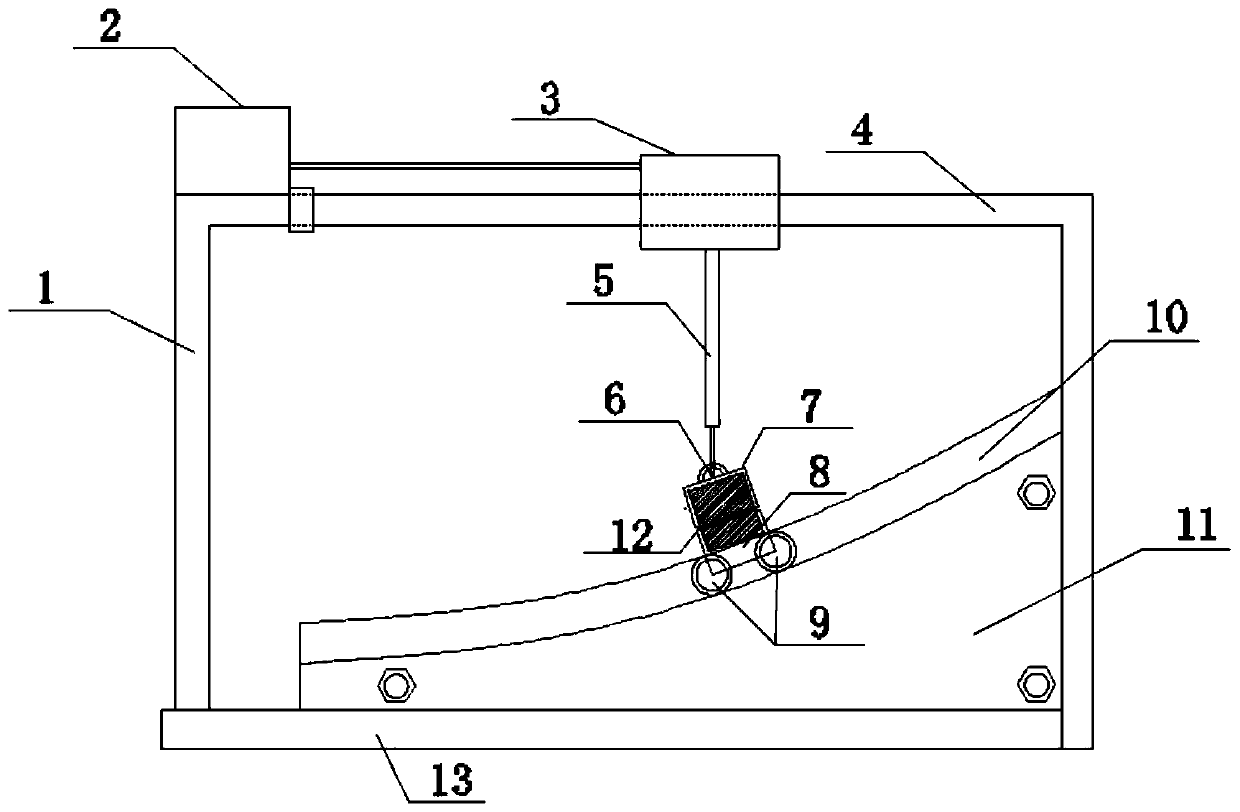

[0026] Such as figure 1 As shown, a pavement interface shear fatigue test device under vehicle braking conditions according to an embodiment of the present invention includes a frame, a guide rail support, a fixing device and a loading device. The frame includes a column 1, a horizontal slideway 4 and a base 13. The horizontal slideway 4 is fixedly connected between the uprights 1 , and the uprights 1 are fixedly connected on both sides of the base 13 . The guide rail support includes a cubic curve guide rail 10 , rollers 9 and specimen fixtures 8 . The roller 9 is connected to the lower part of the specimen holder 8 , and the roller 9 is located in the guide rail 10 and can slide along the guide rail 10 . The fixing device includes upper fasteners 7 and bolts 6 . The upper fastener 7 and the specimen fixture 8 are fastened together. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com