A kind of asphalt mixture ring road rutting test device and test method

An asphalt mixture, rutting test technology, applied in the measurement device, the analysis of materials, the use of applied stable tension/pressure to test the strength of materials, etc. The rutting test time is short and other problems, to achieve the effect of true and reliable rutting test results, improved efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

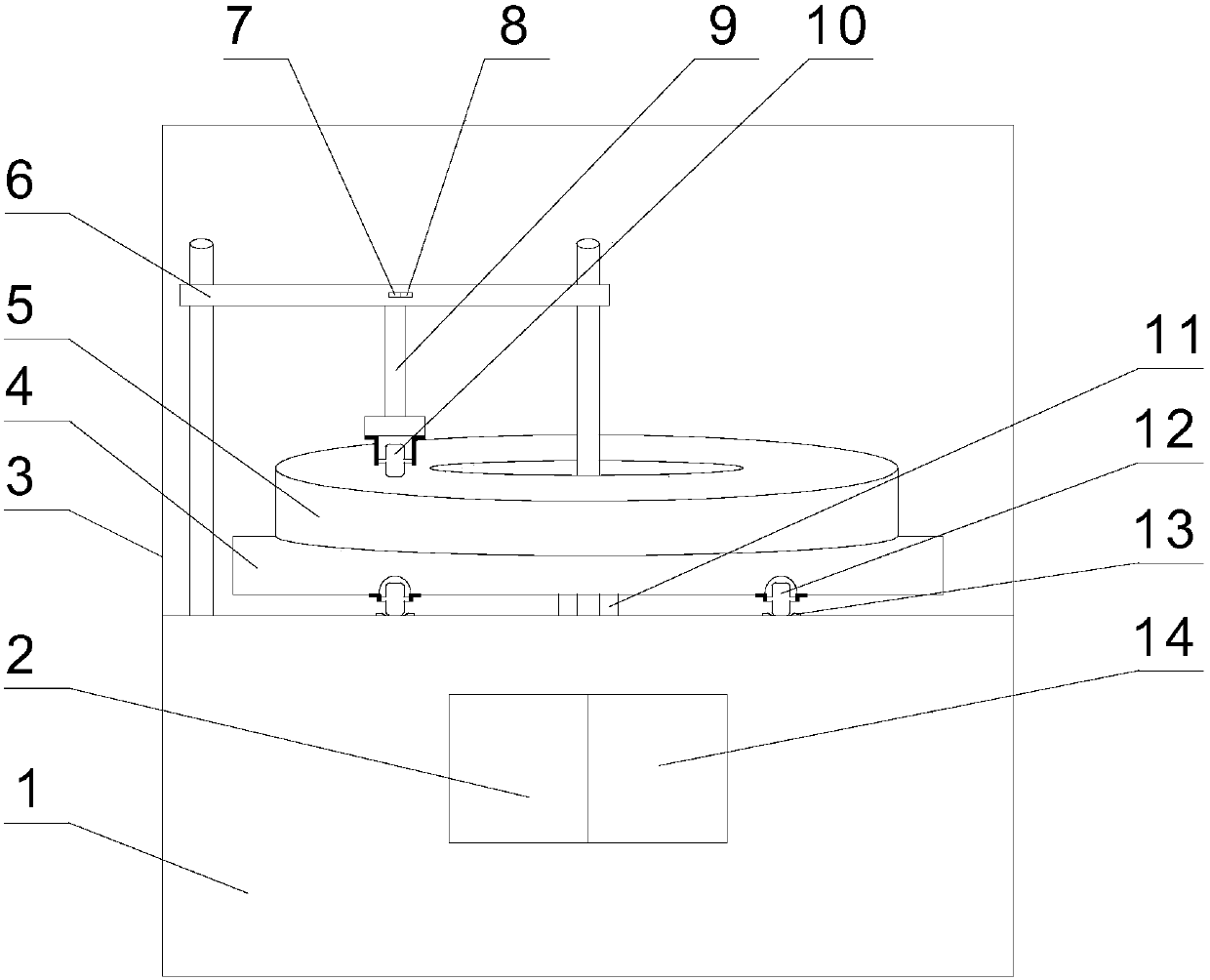

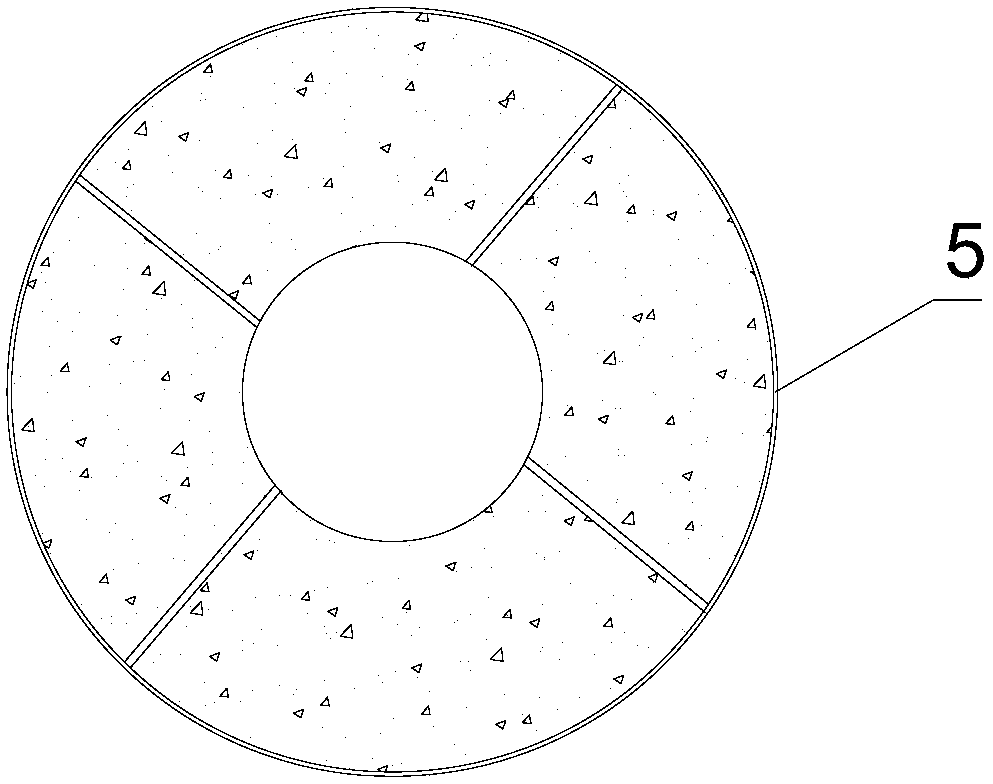

[0035] Depend on figure 1 It can be seen that the asphalt mixture ring road rutting test device of the present embodiment is composed of a working platform 1, a power assembly 2, a temperature control box 3, a placement platform 4, a ring test mold 5, a lifting bracket 6, a pressure sensor 7, a displacement sensor 8, The load fixing rod 9, the wheel load 10, the transmission shaft 11, the acceleration wheel group 12, the controller 14 and the annular guide rail 13 are composed in combination.

[0036]The working platform 1 of the present embodiment provides an installation environment for the whole device, and the power assembly 2 is installed inside the working platform 1, and the controller 14 for controlling each sensor to collect data and the work of the power assembly 2 is installed on the working platform 1, The power assembly 2 includes a lifting motor, a rotating motor and a chain transmission mechanism installed at the power output end of the lifting motor. The power ...

Embodiment 2

[0049] The asphalt mixture ring road rutting test device of this embodiment is the same as that of Embodiment 1, wherein the annular test mold 5 is a single-layer unit test mold, which is used to realize the molding of a single-layer test piece.

[0050] Use the asphalt mixture loop rutting test device to form the rutting test piece first, and then use the device to realize the asphalt mixture loop rutting test method, as follows:

[0051] The method for forming a rutting specimen consists of the following steps:

[0052] (1) Install the roller on the load fixing rod 9 and set the rolling pressure of the roller, open the temperature control box 3, set the rolling forming temperature of the test piece according to the type and performance of the asphalt, and preheat the roller;

[0053] (2) After the temperature control box 3 is preheated to the set rolling temperature, mix the mixture and spread it evenly in the ring test mold 5. After the paving is completed, adjust the heigh...

Embodiment 3

[0061] The rutting test device of the asphalt mixture ring road in this embodiment is the same as that in Embodiment 1, and the annular test mold 5 is composed of four layers of unit test molds laminated, which can realize the forming of the multi-layer composite structure test piece.

[0062] Use the asphalt mixture loop rutting test device to form the rutting test piece first, and then use the device to realize the asphalt mixture loop rutting test method, as follows:

[0063] The method for forming a rutting specimen consists of the following steps:

[0064] (1) Install the roller on the load fixing rod 9 and set the rolling pressure of the roller, open the temperature control box 3, set the rolling forming temperature of the test piece according to the type and performance of the asphalt, and preheat the roller;

[0065] (2) After the temperature control box 3 is preheated to the set rolling temperature, mix the mixture, spread it evenly in the ring test mold 5 in sections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com