Nitrile rubber and PVC mixed vulcanization floor

A technology of nitrile rubber and PVC materials, applied in floor covering, rubber layered products, chemical instruments and methods, etc., can solve the problems of poor anti-skid effect, low strength, poor oil and water resistance, etc., and achieve extended service life and oil resistance. Good performance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

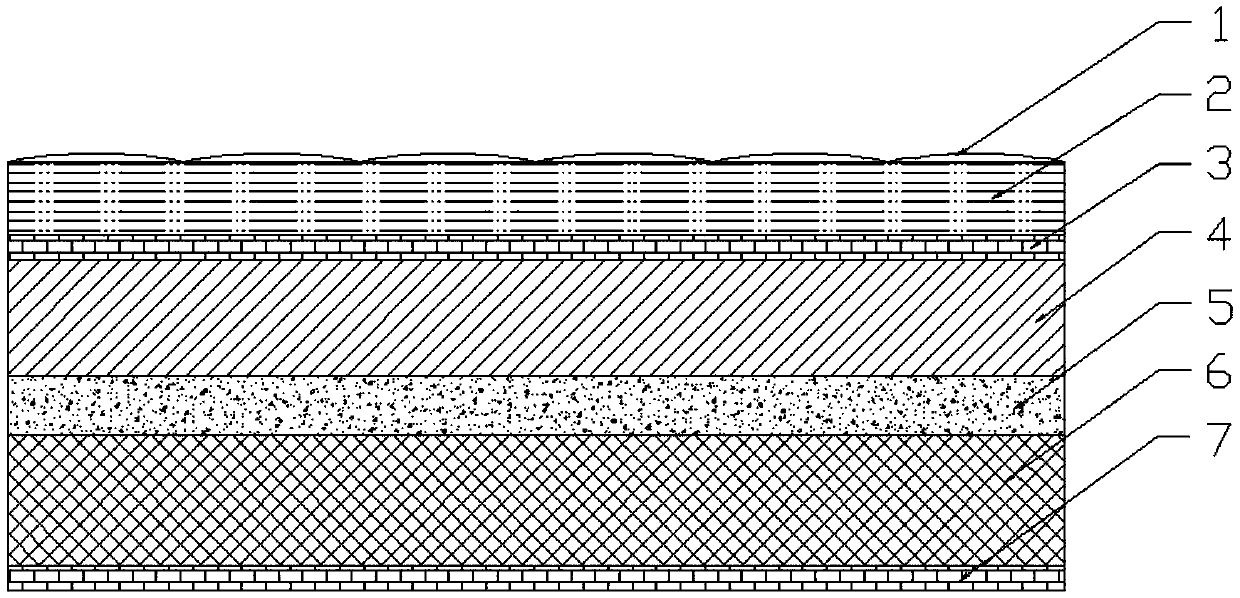

[0021] A mixed vulcanized floor made of nitrile rubber and PVC, comprising an anti-slip layer 1, the lower layer of the anti-slip layer 1 is an oil-resistant layer 2 of nitrile rubber, the lower layer of the oil-resistant layer 2 of nitrile rubber is the first thermal insulation layer 3, and the lower layer of the first thermal insulation layer 3 is the second thermal insulation layer A PVC layer 4, the lower layer of the first PVC layer 4 is a PVC wear-resistant layer 5, the lower layer of the PVC wear-resistant layer 5 is a second PVC layer 6, the lower layer of the second PVC layer 6 is a second insulation layer 7, the first PVC layer 4, The PVC wear-resistant layer 5 and the second PVC layer 6 are mutually extruded to form an integrated structure, and the NBR oil-resistant layer 2 and the first heat insulation layer 3 are also extruded to form an integrated structure.

[0022] In the foregoing embodiment, the anti-slip layer 1 and the nitrile rubber oil-resistant layer 2 ar...

Embodiment 2

[0030] A mixed vulcanized floor made of nitrile rubber and PVC, comprising an anti-slip layer 1, the lower layer of the anti-slip layer 1 is an oil-resistant layer 2 of nitrile rubber, the lower layer of the oil-resistant layer 2 of nitrile rubber is the first thermal insulation layer 3, and the lower layer of the first thermal insulation layer 3 is the second thermal insulation layer A PVC layer 4, the lower layer of the first PVC layer 4 is a PVC wear-resistant layer 5, the lower layer of the PVC wear-resistant layer 5 is a second PVC layer 6, the lower layer of the second PVC layer 6 is a second insulation layer 7, the first PVC layer 4, The PVC wear-resistant layer 5 and the second PVC layer 6 are mutually extruded to form an integrated structure, and the NBR oil-resistant layer 2 and the first heat insulation layer 3 are also extruded to form an integrated structure.

[0031] In the foregoing embodiment, the anti-slip layer 1 and the nitrile rubber oil-resistant layer 2 ar...

Embodiment 3

[0039] A mixed vulcanized floor made of nitrile rubber and PVC, comprising an anti-slip layer 1, the lower layer of the anti-slip layer 1 is an oil-resistant layer 2 of nitrile rubber, the lower layer of the oil-resistant layer 2 of nitrile rubber is the first thermal insulation layer 3, and the lower layer of the first thermal insulation layer 3 is the second thermal insulation layer A PVC layer 4, the lower layer of the first PVC layer 4 is a PVC wear-resistant layer 5, the lower layer of the PVC wear-resistant layer 5 is a second PVC layer 6, the lower layer of the second PVC layer 6 is a second insulation layer 7, the first PVC layer 4, The PVC wear-resistant layer 5 and the second PVC layer 6 are mutually extruded to form an integrated structure, and the NBR oil-resistant layer 2 and the first heat insulation layer 3 are also extruded to form an integrated structure.

[0040] In the foregoing embodiment, the anti-slip layer 1 and the nitrile rubber oil-resistant layer 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com