Cement emulsified asphalt mortar penetrating-type semi-rigidity road surface construction vibration rolling apparatus

A cement-emulsified asphalt, semi-rigid technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of cement-emulsified mortar paving and inconvenient penetration, and achieve the effect of novel concept, strong practicability and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

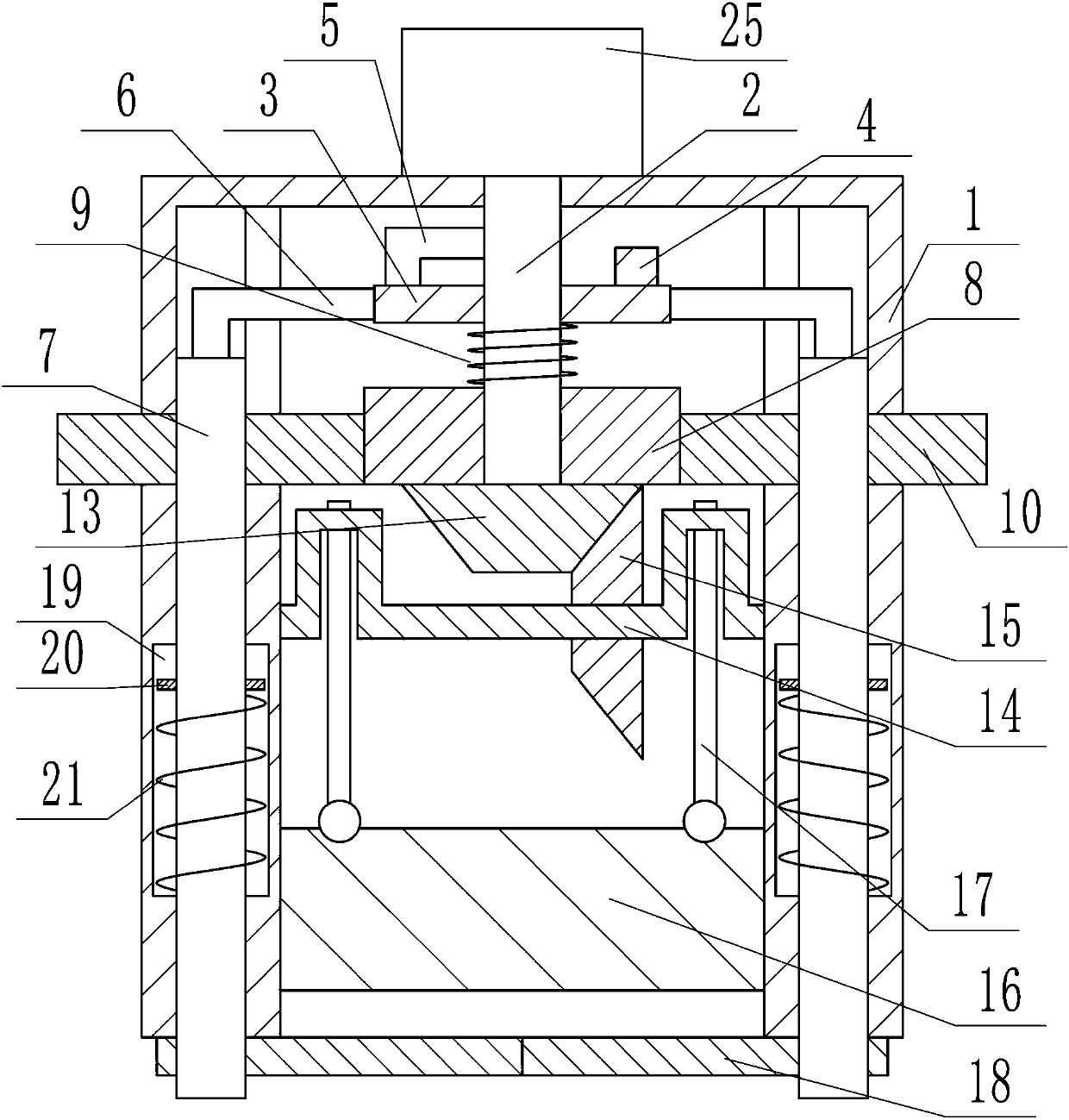

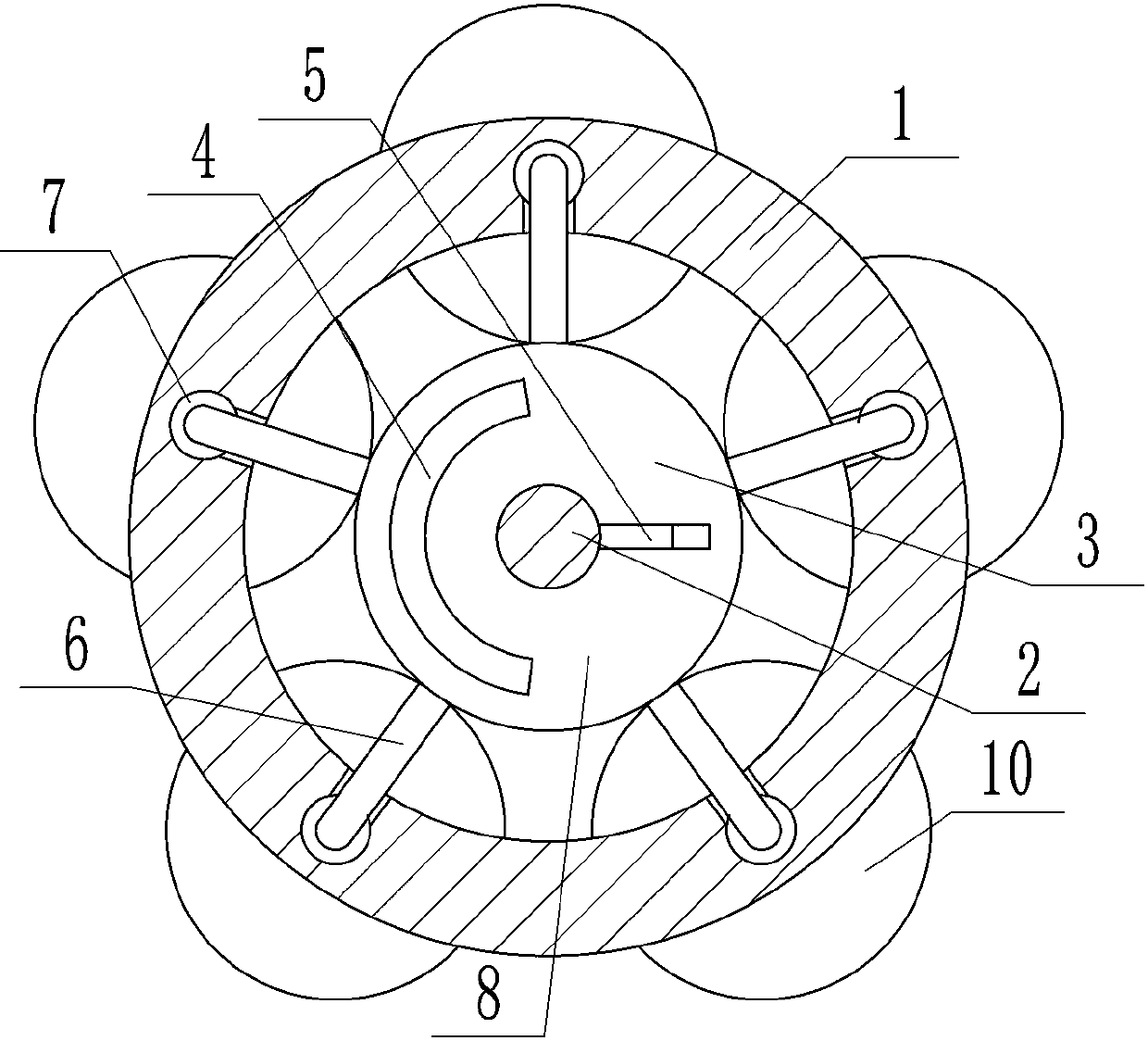

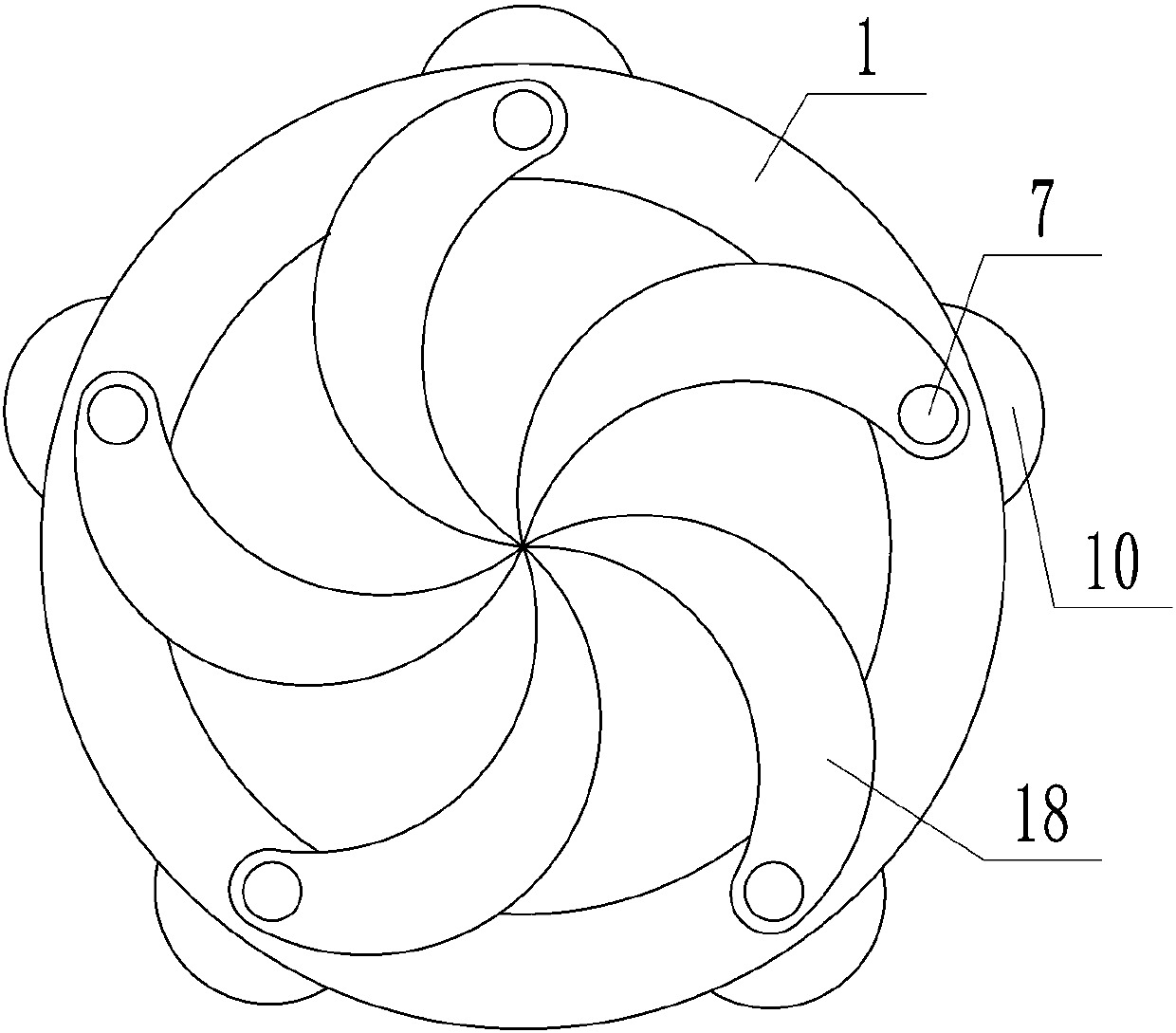

[0019] Depend on Figure 1 to Figure 8 It can be seen that the present invention includes a cylinder 1 placed vertically and with its upper end closed and its lower end open. A drive shaft 2 is installed in the center of the cylinder 1. A fixed plate 3 that can move up and down is set on the drive shaft 2. The fixed plate 3 does not rotate with the drive shaft 2. The upper end surface of the fixed plate 3 is provided with an arc-shaped protruding block 4 along its circumferential direction, one end of the arc-shaped protruding block 4 is flush with the upper end surface of the fixed plate 3, and the other end protrudes from the upper end surface of the fixed plate 3 and both ends are smooth connection, the transmission shaft 2 is fixed with a vertical bar 5 placed above the arc-shaped raised block 4 and can slide the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com