Bubble overflow preventing washing machine

A washing machine and anti-foaming technology, which is applied to other washing machines, washing machine control devices, washing devices, etc., can solve problems such as motor stalling, powerlessness, floor damage, and impact on hygiene, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described now.

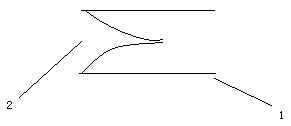

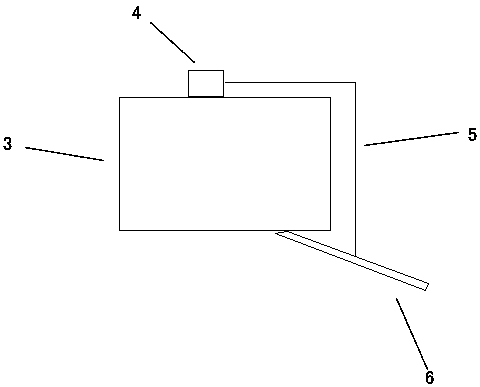

[0023] An anti-foam overflow washing machine, the washing machine has a casing, an outer tub 3 with a front door opened inside the casing, and a rotatable drum arranged in the outer tub 3, the water inlet valve leads the washing water to the detergent box, the The detergent box is connected to the outer tub 3 through a hose 1, and the feature is that the hose 1 has a normally closed structure 2, and the outer tub 3 also has a foam suction pump 4 for discharging foam.

[0024] Preferably, the normally closed structure 2 is an elastic rubber tube arranged in the hose 1. One end of the elastic rubber tube is connected to the water inlet end of the hose, and the other end is an elastic closed structure. When entering, the elastic closing structure is flushed away from the incoming water, and the foam cannot overflow into the hose 1 from the reverse direction and enter the detergent box.

[0025] Preferably, the foam su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com