Transformer oil temperature detection system

A technology of transformer oil and detection system, which is applied in the direction of transformer/inductor cooling, thermometer, transformer/inductor parts, etc. It can solve problems such as unsatisfactory detection requirements, transformer insulation hazards, transformer short circuit, etc., and achieves simple structure and easy to use Convenience, detection and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

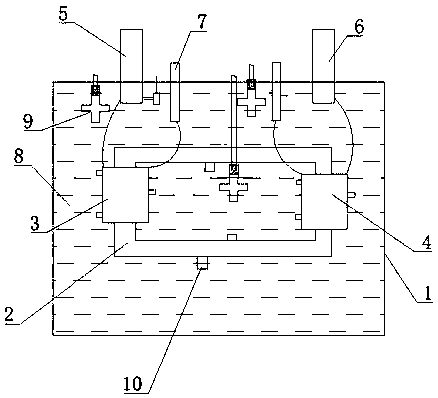

[0016] Such as figure 1 As shown, the transformer oil temperature detection system includes an oil tank 1 with an iron core 2 inside. A high-voltage coil 3 and a low-voltage coil 4 are wound on the iron core 2. The upper part of the high-voltage coil 3 is connected to the high-voltage insulating bushing 5 on the oil tank 1. 4 is connected to the low-voltage insulating bushing 6 on the oil tank 1, and the upper part of the oil tank 1 is also equipped with a tap switch 7 for adjusting the number of coil turns. The oil tank 1 is filled with transformer oil 8; the oil tank 1 is equipped with a plurality of ceramic heating plates 9 The iron core 2, the high-voltage coil 3, and the low-voltage coil 4 are wound with a plurality of thermal radiation optical fiber sensors 10, and the thermal radiation optical fiber sensors 10 are respectively arranged on the upper, middle and lower parts of the iron core 2, the high-voltage coil 3, and the low-voltage coil 4, and the thermal radiation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com