Roller micromotion adjusting device of elasticizer

A technology of adjusting device and texturing machine, which is applied in the direction of textiles and paper making, can solve the problems of only utilization, slow speed, poor clamping effect, etc., and achieve the effect of expanding the range, prolonging the service life, and changing the degree of compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

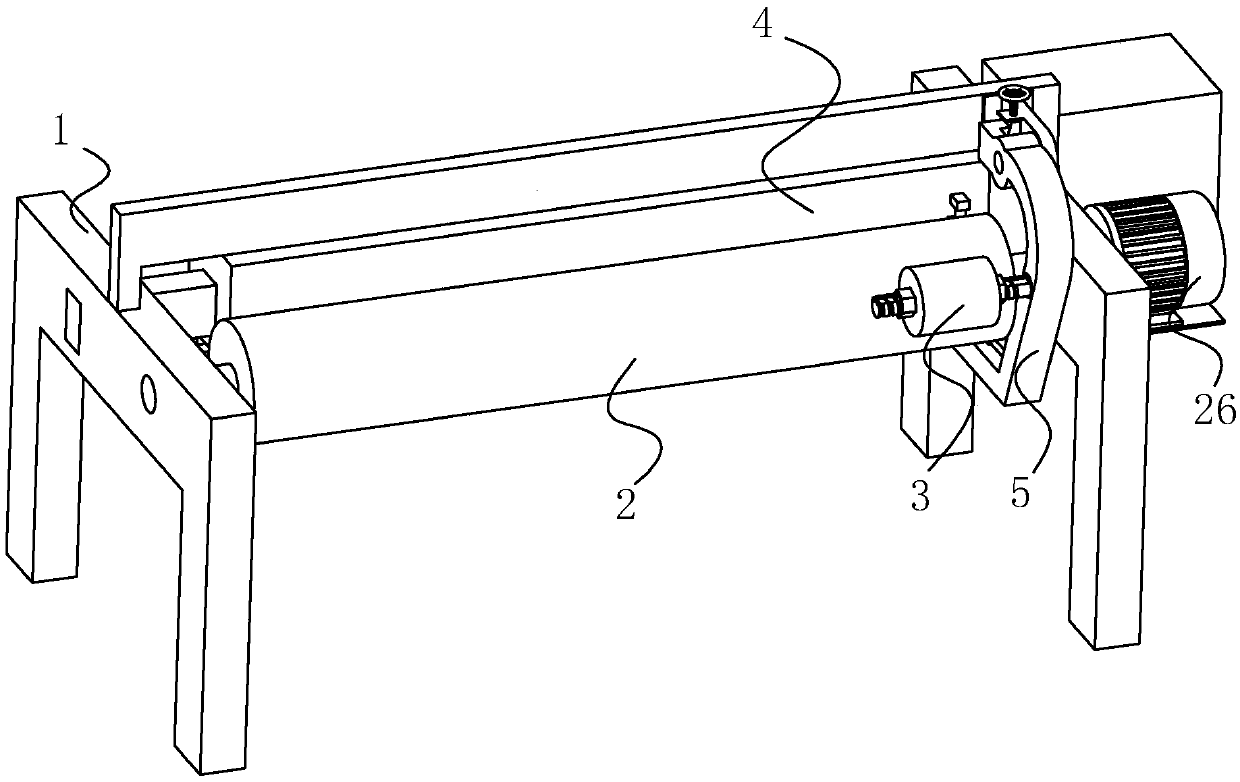

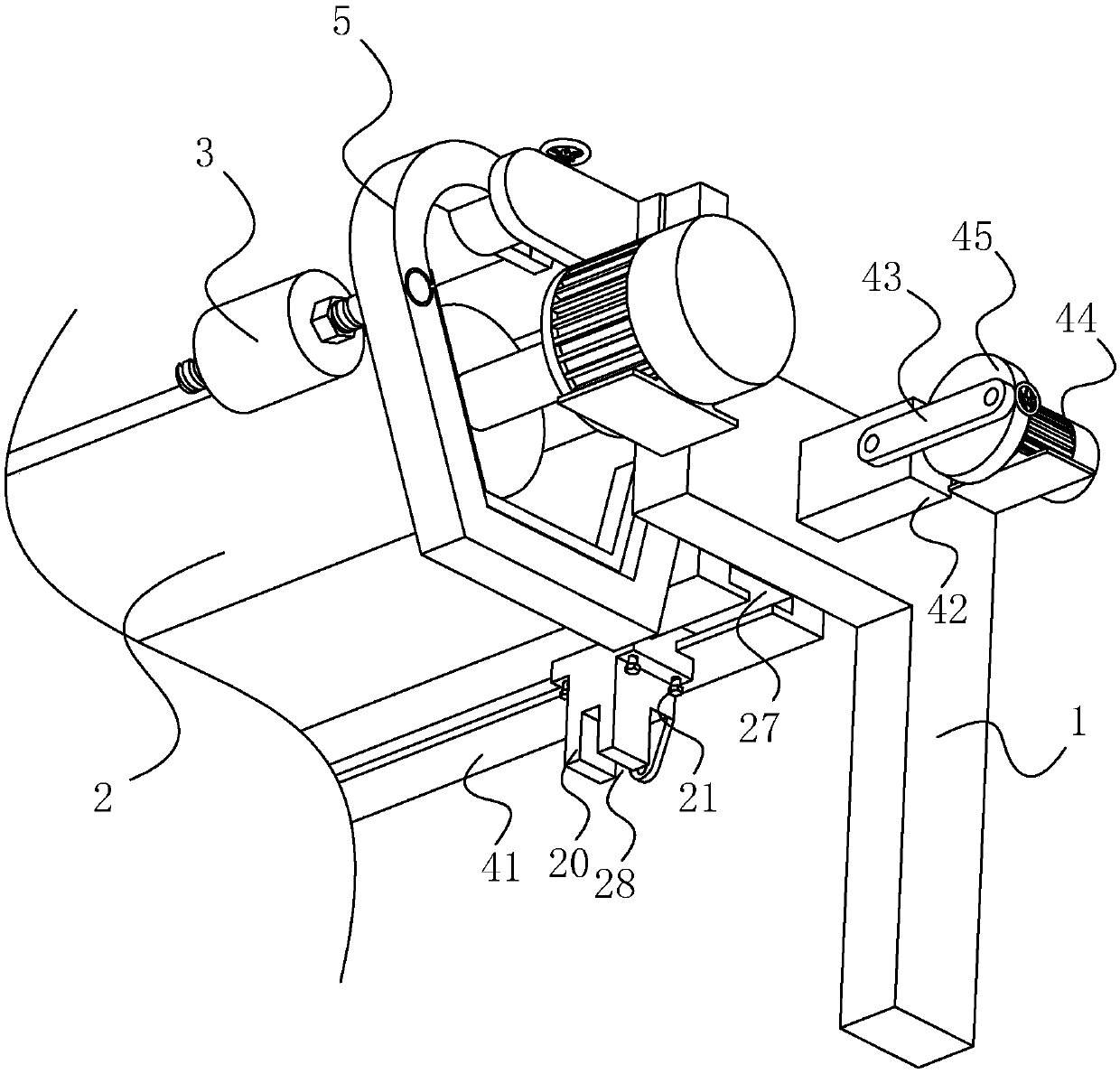

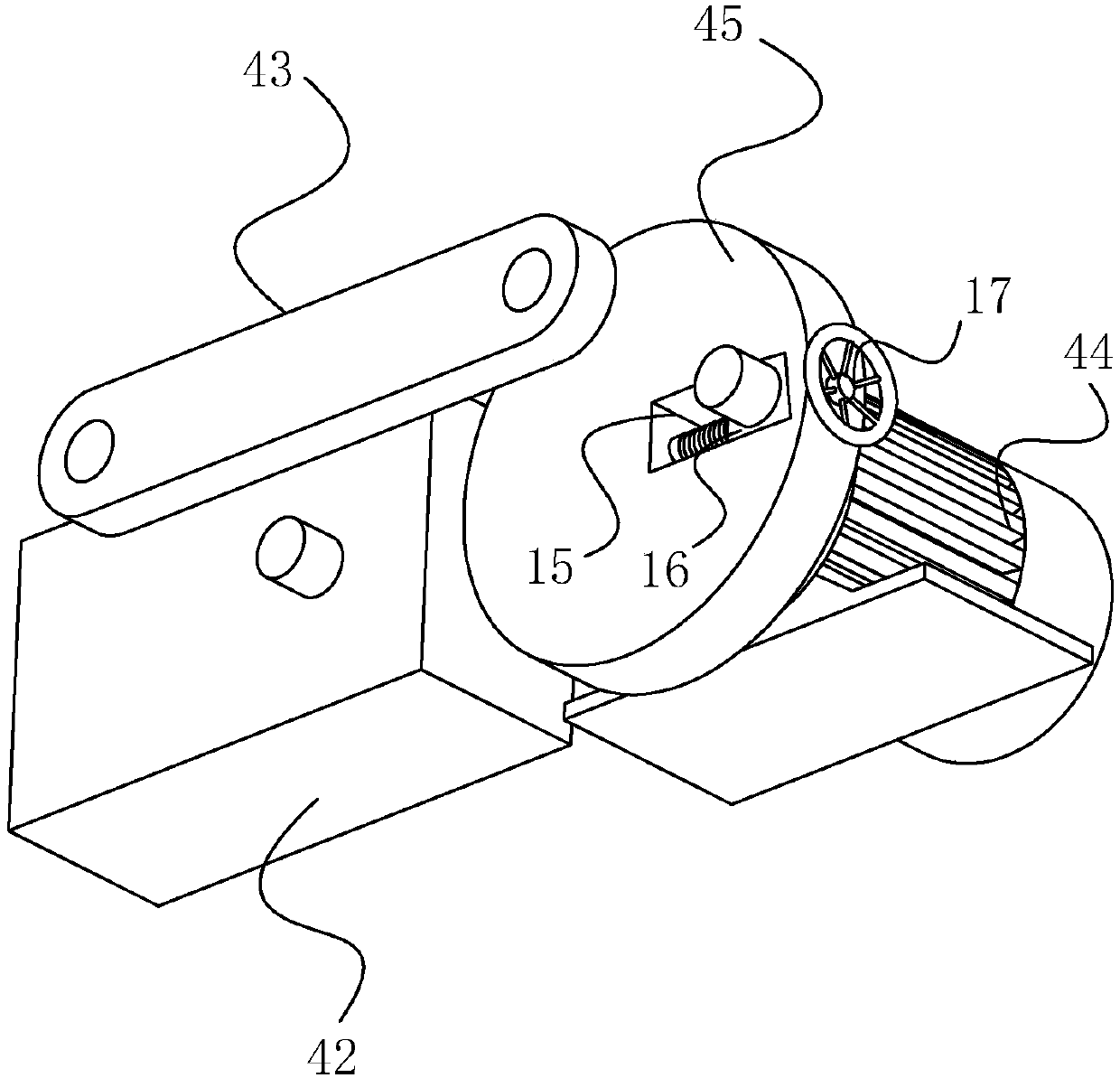

[0037] A roller micro-adjustment device for a texturing machine, refer to figure 1 Shown, comprise support 1, on support 1, be connected with a roller roller 2 that is horizontally arranged in rotation, be positioned at the rear of roller roller 2 in support 1, be provided with wire-moving device 4, be provided with mounting frame 5 in front of roller roller 2, The mounting frame 5 is hinged to the bracket 1, and the mounting frame 5 is rotatably connected with a top roller 3 whose axial direction is parallel to the axial direction of the roller roller 2. During the process, the yarn is driven by the wire transfer device 4 to move along the axial direction of the roller roller 2, so that the yarn does not only touch the same position on the outer wall of the roller roller 2 and the top roller 3.

[0038] The roller roller 2 is driven by a main motor 26 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com