Aluminum magnesium alloy for casting two-breadth-type steering wheel framework and preparation method thereof

A technology of aluminum-magnesium alloy and steering wheel, which is applied in the field of metal materials and magnesium-aluminum alloy preparation, can solve the problems of magnesium alloy oxidation, burning loss, high cost, etc., and achieve improved alloy strength, excellent formability and corrosion resistance, and good high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

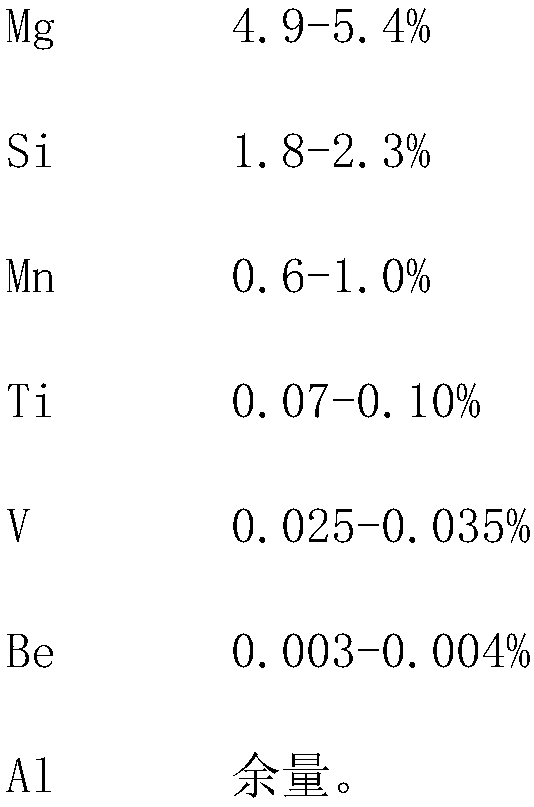

[0032] An aluminum-magnesium alloy for casting a two-spoke steering wheel skeleton. The innovation of the present invention is that the components and weight percentages are as follows:

[0033]

[0034] In this embodiment, impurity element control:

[0035] Fe≤0.13%, Zn≤0.03%, Cu≤0.01%, Cr≤0.0005%, P≤0.001%, Na≤0.0005%, Ca≤0.0005%, Li≤0.001%, Al balance.

[0036] In this embodiment, the raw materials used include:

[0037] Electrolytic aluminum with grade Al99.85 is used, and its impurity element requirements are: Fe≤0.12%, Zn≤0.03%, Cu≤0.005%, and other individual elements≤0.005%;

[0038] Primary magnesium ingots with a grade of Mg99.95 are used, and the requirements for impurity elements are: Fe≤0.003%, Zn≤0.01%, Cu≤0.002%, and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com