Preparation method and application of drone pupa small-molecular antioxidant peptide

A technology for antioxidant peptides and small molecules, which is used in the preparation methods of peptides, chemical instruments and methods, and medical preparations containing active ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a drone pupae small-molecule antioxidant peptide, comprising the following steps:

[0031] 1) Mix and homogenize the drone pupae powder with water, adjust the pH value of the homogenate to 6-7, mix it with a compound enzyme, and enzymolyze it at 50-60°C for 1-3 hours to obtain an enzymolysis solution, and the compound Enzymes include endoprotease and exoprotease; 2) Centrifuge the enzymatic hydrolyzate obtained in the step 1), filter the obtained supernatant to obtain a filtrate, and the speed of the centrifuge is 4000-5000rpm, The pore size of the filter cloth used for the filtration is 1-5 μm; 3) The filtrate obtained in the step 2) is subjected to the first step of ultrafiltration to separate the peptide segment to obtain an ultrafiltrate with a molecular weight of the peptide segment <1 ku, and the first step The molecular weight cut-offs of the ultrafiltration membranes used in the step ultrafiltration are 10ku, 5ku, 3k...

Embodiment 1

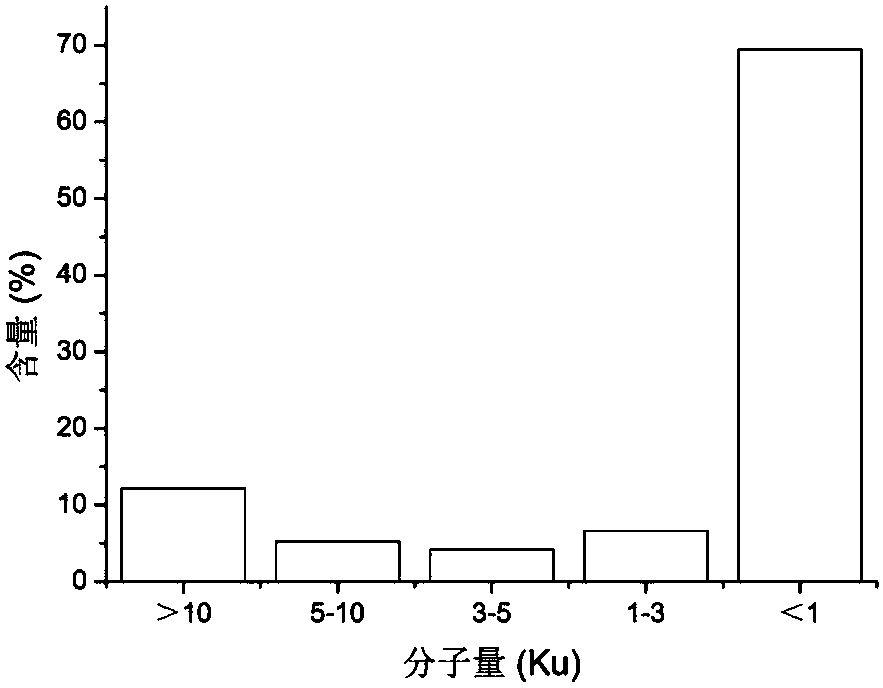

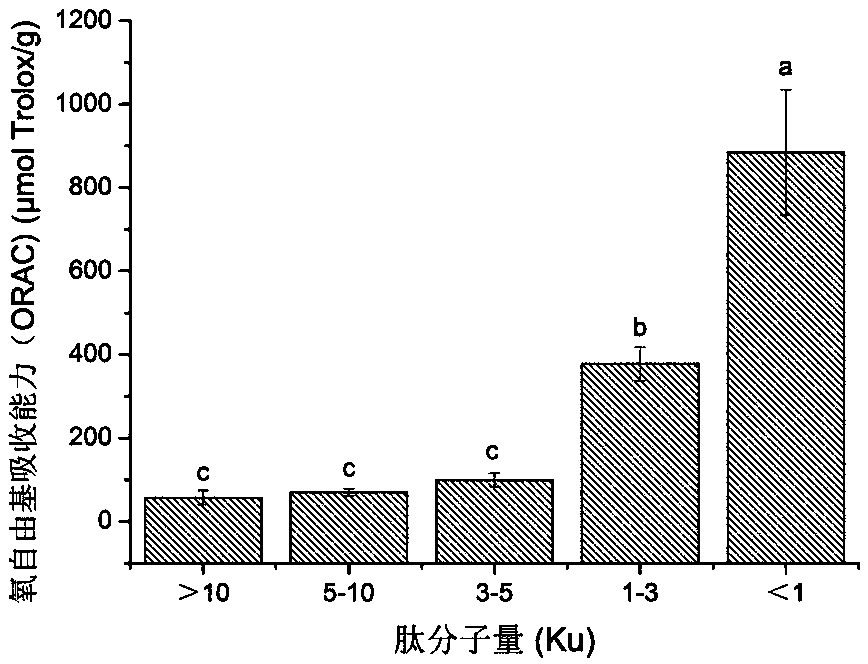

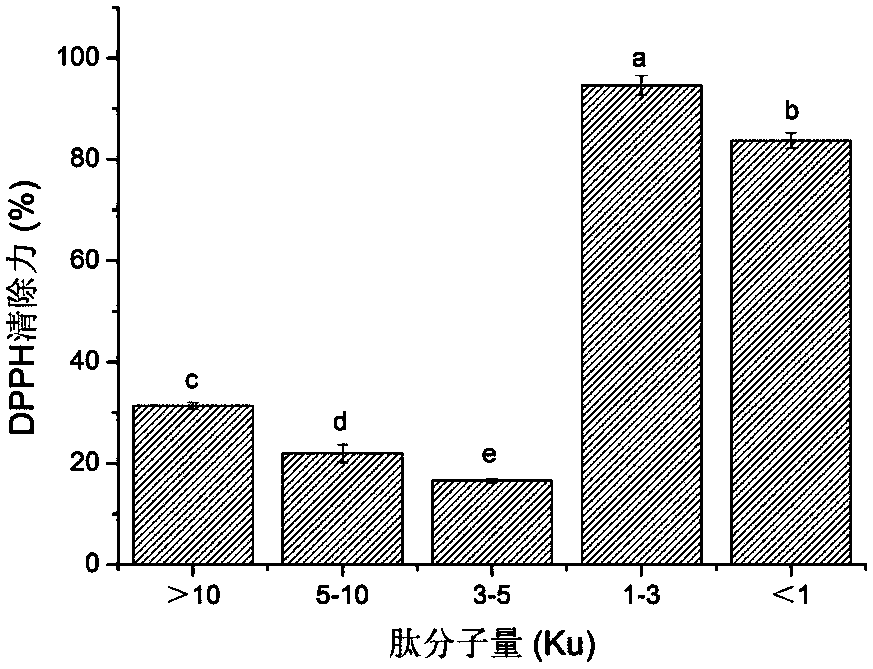

[0056] Grind the freeze-dried drone pupae into powder, pass through a 80-mesh sieve, add water 15 times the weight of the freeze-dried drone pupae, and homogenate, adjust the pH to 6.5 with dilute hydrochloric acid and low-concentration sodium hydroxide solution, add compound enzymes at 60°C Under enzymolysis for 2h, the enzymolysis solution was obtained (see figure 1 ), the compound enzyme is neutral protease and flavor protease, and every 1g of drone pupae powder is added with a compound enzyme whose total enzyme activity is 1760U, and the enzyme activity ratio of neutral protease and flavor protease is 3:1.

[0057] Centrifuge the enzymatic solution at 4000rpm for 15min, discard the upper layer of grease, take the supernatant and pass it through a 5μm filter cloth, and use the ultrafiltration membrane with a molecular weight cut-off of 1ku to perform the first step of ultrafiltration to separate the peptide segment to obtain the peptide segment For the ultrafiltrate with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com