Mortar stirring machine

A mixer and mortar technology, applied in cement mixing devices, food science, clay preparation devices, etc., can solve the problems of affecting the quality of pulp, blocking the outlet, and agglomerated materials, so as to ensure the quality of pulp and prevent blockage , The stable effect of pulping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

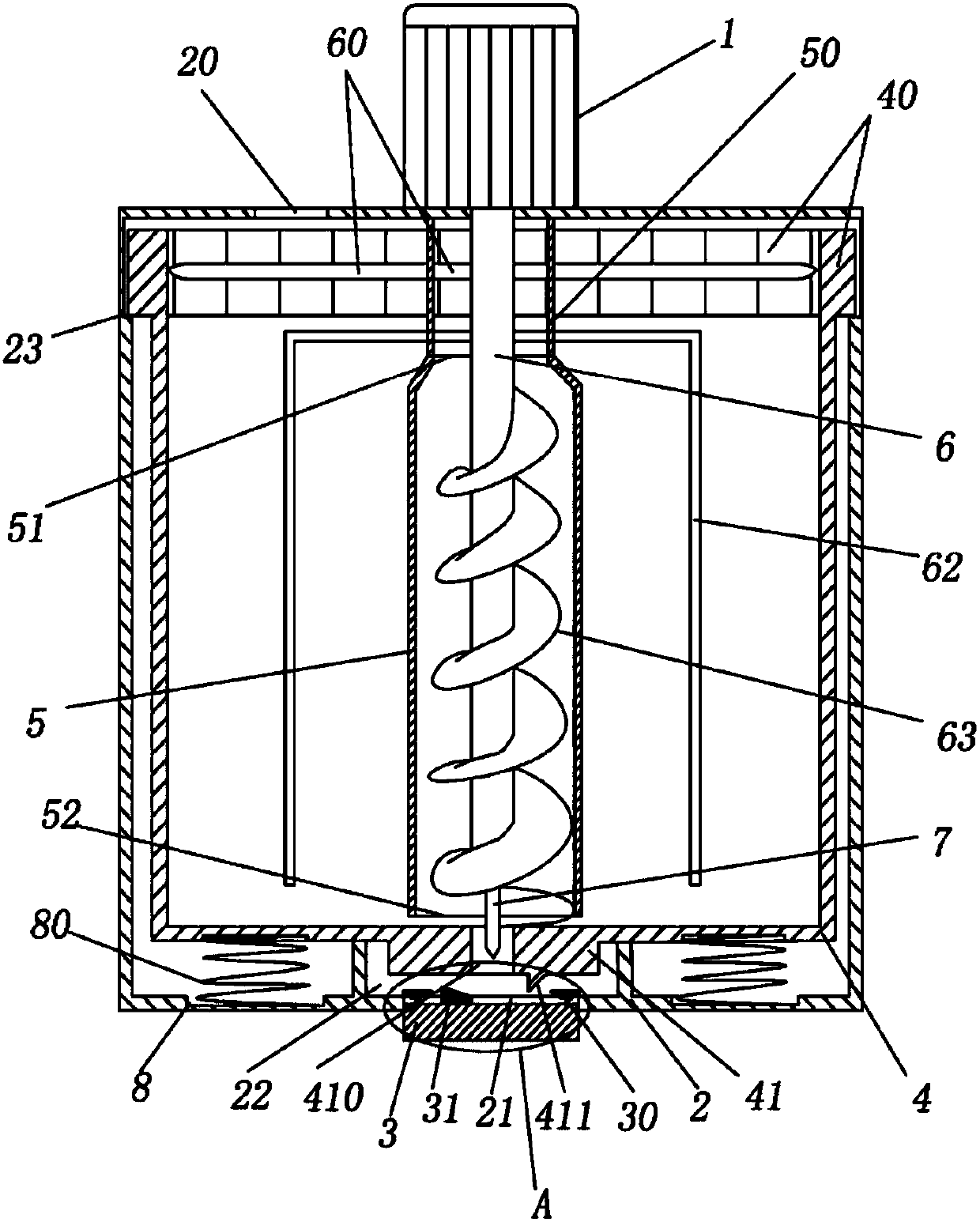

[0022] The reference signs in the accompanying drawings of the specification include: motor 1, fixed barrel 2, feed port 20, discharge port 21, grinding chamber 22, groove 23, sealing plug 3, return tension spring 30, moving block 31, rotating barrel 4. Ratchet ring 40, grinding disc 41, connecting hole 410, toggle block 411, traction barrel 5, fixing strip 50, discharge port 51, material introduction port 52, stirring rod 6, pawl 60, limit extension spring 61 , Stirring blade 62, spiral blade 63, dredging rod 7, annular groove 8, stage clip 80.

[0023] The embodiment is basically as attached figure 1 Shown:

[0024] A mortar mixer, including a motor 1, a stirring paddle and a mixing bucket.

[0025] The mixing bucket includes a fixed bucket 2, a rotating bucket 4 and a pulling bucket 5, the rotating bucket 4 is located in the fixed bucket 2, and the pulling bucket 5 is located in the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com