Heat-not-burn cigarette

A heat-not-burn, cigarette technology, applied in the direction of tobacco, e-liquid filter, application, etc., can solve the problems of sour taste, burnt taste of acetate fiber filter rod, and small smoke volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] Liqun (Sunshine) cigarette shredded tobacco is selected as the design object in this embodiment. The method for designing heat-not-burn cigarettes based on traditional cigarettes, the specific implementation methods are as follows:

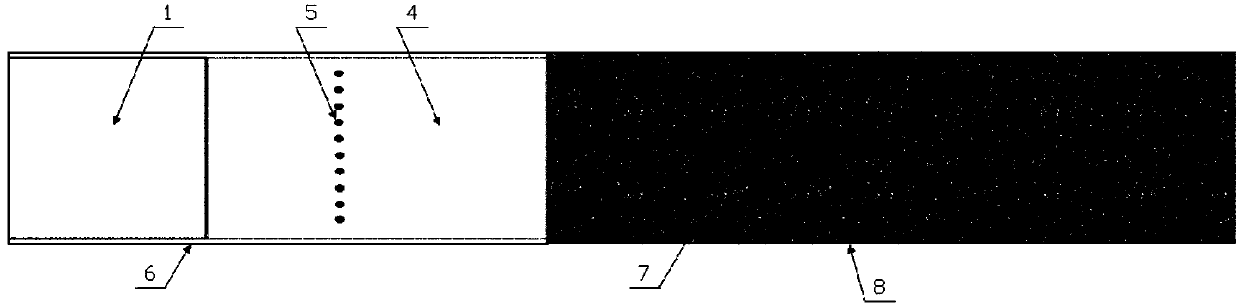

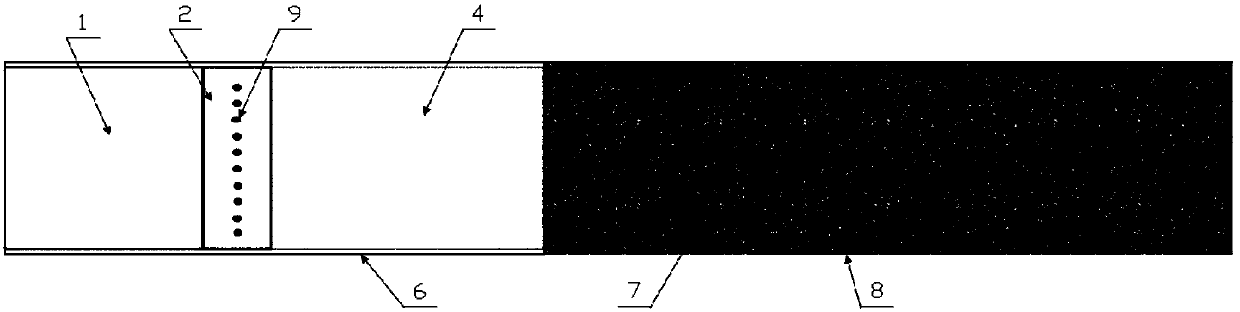

[0023] Such as figure 1 The shown heat-not-burn cigarette includes a shredded tobacco section and a filter section. The length of the shredded tobacco section is 50mm, the length of the filter section is 34mm, and the circumference of the cigarette is 24.5mm.

[0024] The cut tobacco section and the filter section are bonded and connected by tipping paper; the basis weight of the tipping paper is 39.5g / m 2 , the air permeability is 400cu, the length is 40mm, and the glue-free area is (10×21)mm.

[0025] The shredded tobacco segment includes shredded tobacco 7 and cigarette paper 8 wrapping the shredded tobacco 7. The shredded tobacco 7 is made of Liqun (Sunshine) shredded tobacco, and the air permeability of the cigarette paper 8 is 60cu....

Embodiment 2

[0035] In this embodiment, the expanded shredded tobacco is selected as the design object. The method for designing heat-not-burn cigarettes based on traditional cigarettes, the specific implementation methods are as follows:

[0036] Such as figure 1 The shown heat-not-burn cigarette includes a shredded tobacco section and a filter section. The length of the shredded tobacco section is 56mm, the length of the filter section is 28mm, and the circumference of the cigarette is 24.5mm.

[0037] The shredded tobacco section and the filter section are bonded and connected by tipping paper 6; the weight of tipping paper 6 is 80g / m 2 , the air permeability is 300cu, the length is 36mm, and the glue-free area is (10×21)mm.

[0038] The shredded tobacco section includes shredded tobacco 7 and cigarette paper 8 wrapping the shredded tobacco 7 , the shredded tobacco 7 is expanded shredded tobacco, and the air permeability of the cigarette paper 8 is 60cu.

[0039] The filter section i...

Embodiment 3

[0046] Liqun (Sunshine) cigarette shredded tobacco is selected as the design object in this embodiment. The method for designing heat-not-burn cigarettes based on traditional cigarettes, the specific implementation methods are as follows:

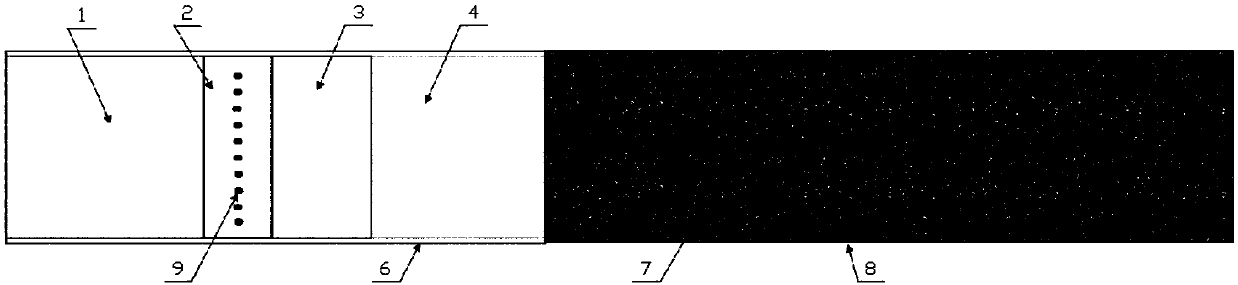

[0047] Such as image 3 The shown heat-not-burn cigarette includes a shredded tobacco segment and a filter tip segment, and the shredded tobacco segment and the filter tip segment are bonded and connected by tipping paper 6; the weight of the tipping paper is 80g / m 2, the air permeability is 300cu, the length is 40mm, and the non-adhesive area is (10×21)mm.

[0048] The shredded tobacco section includes shredded tobacco 7 and cigarette paper 8 wrapping the shredded tobacco 7. The shredded tobacco 7 is shredded tobacco from Liqun (Sunshine) cigarettes, and the air permeability of the cigarette paper 8 is 60cu.

[0049] The filter section includes a filter 1 and a paper empty tube 4, and the paper empty tube 4 is connected to the end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com